Mines on an RF45 known as many others inc Chester Super Lux, Warco and many others.

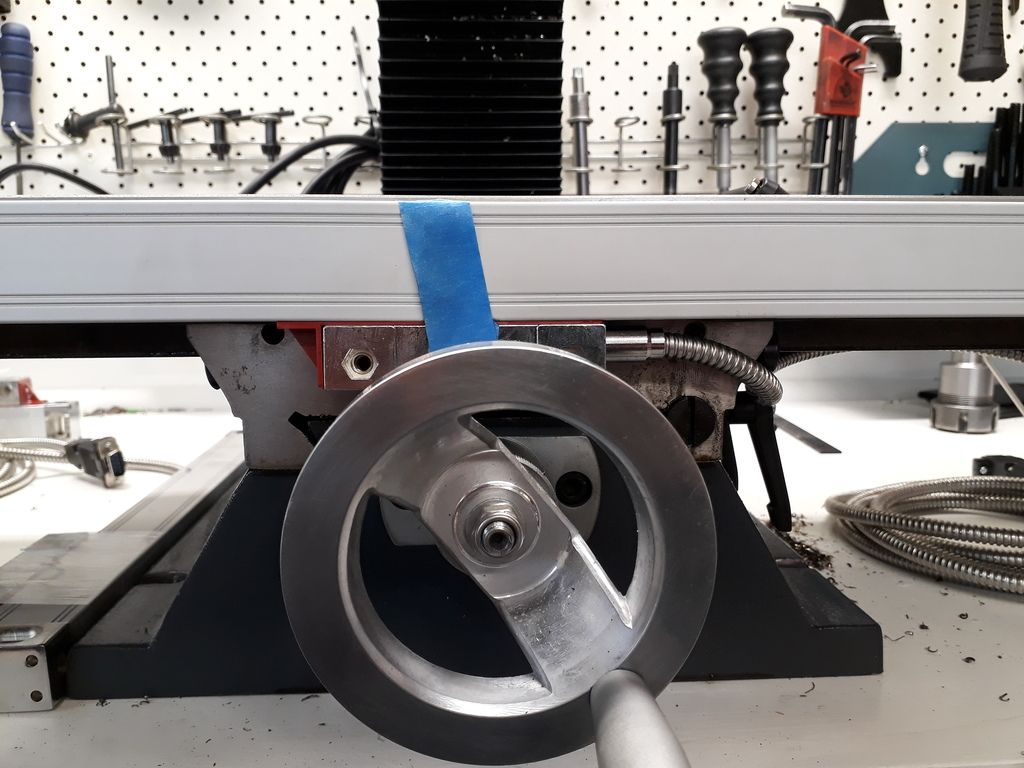

Short table on yours Clive, mine did have a true 23 3/4" X travel now around 21 1/2" with power feed.

Trust me you will need the bed locks and mounting on the front negates that.

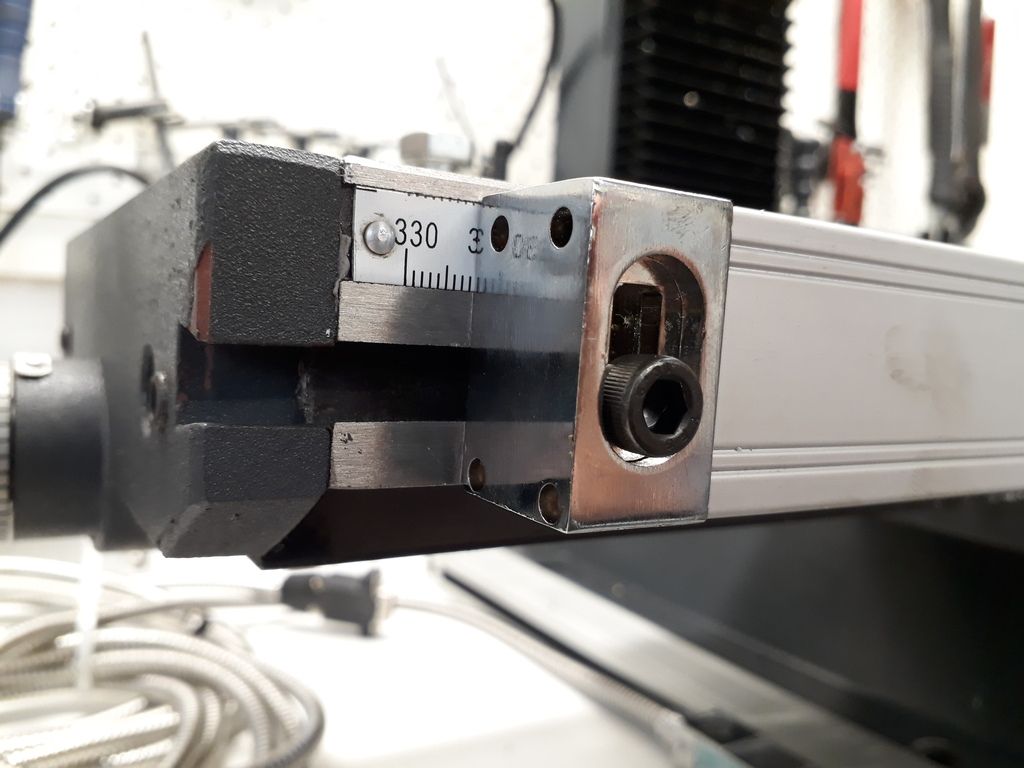

Stops may be ok to do using the originals, just pull away the scale to tighten up in place.

Power feed stops on mine use hex head screws so could go in vertically with an open ended spanner but painfull.

Also means cant fit a proper power feed with trips on front T slot with any access, mine has 34mm stand off.

So far that means inner scale would have to be min 35mm stand off plus an extra 2" for covers. Means handle Y axis handle goes underneath the outboard scale remotely approaching full width of travel.

For me additionally i have an 8" RT, dividing plates drop down below the T slot and only have around 3/4" to do so just clearing the one end stop!

Its actually easier to fit on rear, four or five drill and taps, fit and away you go. Been 13 years.

If fit on front it has to be beefy with the stand off even more so with the reader. I did a compare some years back on the errors factory cheap vernier type scales have using supplied mountings. Though seem rigid can have an easy 0.26mm error, mouting out board will amplify any flex or movement which defeats the object. Got piccies some where.

Wish the magnetic were around when i did mine and would have gone inside along the lead screw, best of both worlds but hard to fit.

Thaddeus Swarfburn III.