Posted by Ajohnw on 02/01/2017 17:28:23:

Rather than the usual ME designs I'd suggest the Myfordboy one that can be found on youtube. That one seems to work extremely well and I doubt if it's expensive or difficult to build.

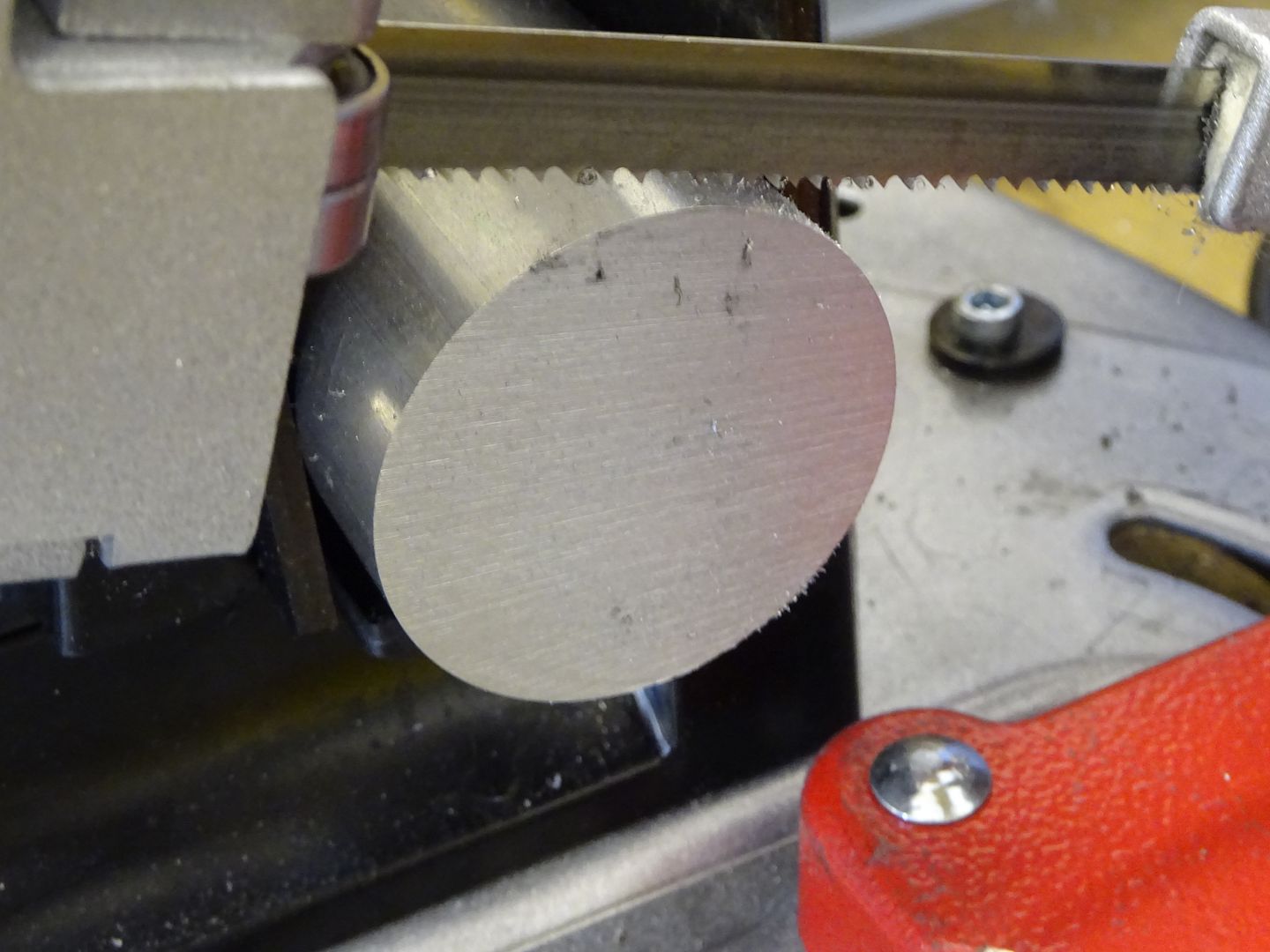

Bound to need a hacksaw though or any of the other ideas. I have cut stuff with an angle grinder at times. Usually thin stuff. It takes time. If I needed to cut stuff that wouldn't fit in the bandsaw often I would probably buy one of the metal cutting circular saws. Myfordboy demo's the use of one of those in one of his video's. Think it's on a some metal rolls that didn't work out as good as his own design.

Bound to need a hacksaw though or any of the other ideas. I have cut stuff with an angle grinder at times. Usually thin stuff. It takes time. If I needed to cut stuff that wouldn't fit in the bandsaw often I would probably buy one of the metal cutting circular saws. Myfordboy demo's the use of one of those in one of his video's. Think it's on a some metal rolls that didn't work out as good as his own design.

John

–

I have seen the myfordboy auto-hacksaw design, and even a few castings for sale to help you make one, it would be a novel idea and quite a rewarding project if you planned it in advance. You could certainly say "not many have got one of these!" It would probably be quite mesmerizing to watch too.

My only argument against it being the "best" would be the time and effort involved into making one materialise, and possibly ironing out any niggles from our own homemade components in service! For a quick, remedial bought solution, the D.I.Y bandsaw certainly fills the brief. It does have one plus over the bandsaw, and that is size. So if that's a big problem for you, then maybe a project would be a better option for a bespoke solution.

I have considered anglegrinders as well and my main objection to them would be the flurry of dust and noise the abrasive action would make, cutting with the bandsaw on the other hand, although creating swarf, is much more manageable because it cuts at a relatively low speed, just like the auto hacksaw,

interestingly, the chopsaw suffers from the same downsides as the grinders, lots of noise and mess, I have had to clear heaps of aluminium swarf away from a little "cutting booth" created in a workshop I worked at simply because the chop saw so messy, you would end up with a metallic spray all over your overalls. However, it does cut far quicker than the bandsaw, however we are not time constrained on this end of the market, and perhaps care a little more about our interior spaces.

Michael W

Edited By Michael-w on 02/01/2017 18:21:50

Edited By Michael-w on 02/01/2017 18:23:32

Howard Lewis.

They will also cut timber ideally with a coarser blade.

They will also cut timber ideally with a coarser blade.