bending small bore copper pipe

bending small bore copper pipe

- This topic has 14 replies, 10 voices, and was last updated 19 December 2017 at 09:38 by

David Carpenter 4.

Viewing 15 posts - 1 through 15 (of 15 total)

Viewing 15 posts - 1 through 15 (of 15 total)

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

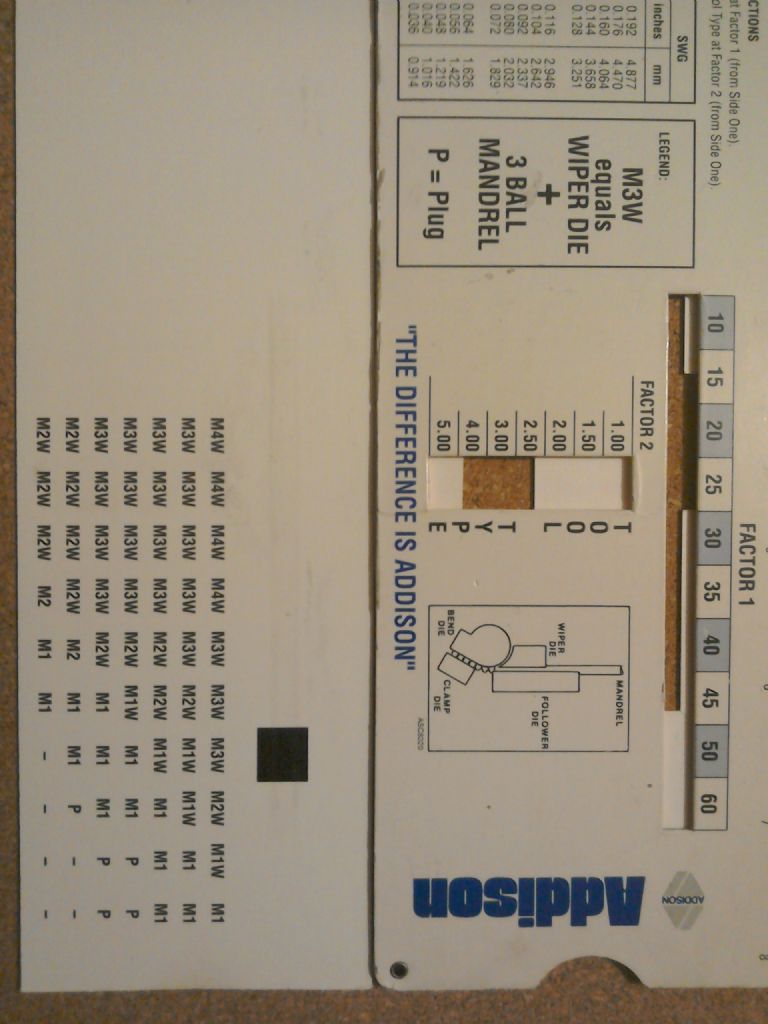

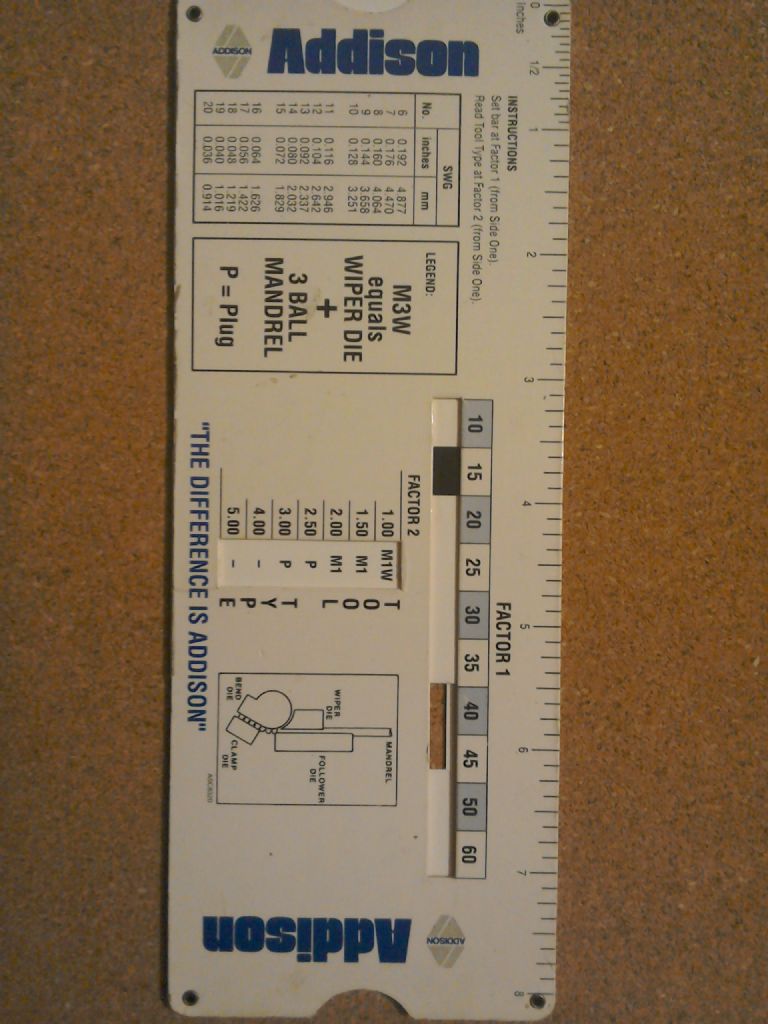

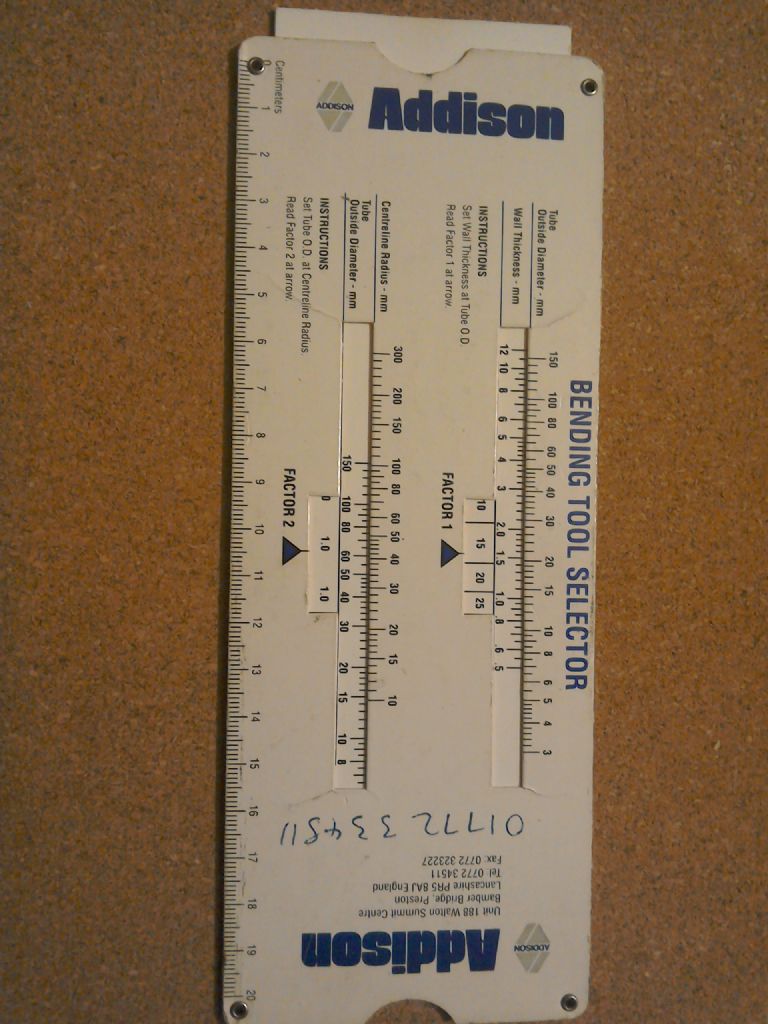

the factor 2 value is 3. The result is the table says this bend needs a plug mandrel but no wiper die. Reduce the bend radius to 3/4" and it says a one ball mandrel with wiper die.

the factor 2 value is 3. The result is the table says this bend needs a plug mandrel but no wiper die. Reduce the bend radius to 3/4" and it says a one ball mandrel with wiper die.