Anyone care to scrutinise some drawings?

Anyone care to scrutinise some drawings?

- This topic has 17 replies, 9 voices, and was last updated 20 January 2016 at 19:46 by

John Hinkley.

John Hinkley.

Viewing 18 posts - 1 through 18 (of 18 total)

Viewing 18 posts - 1 through 18 (of 18 total)

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

Latest Issue

Newsletter Sign-up

Latest Replies

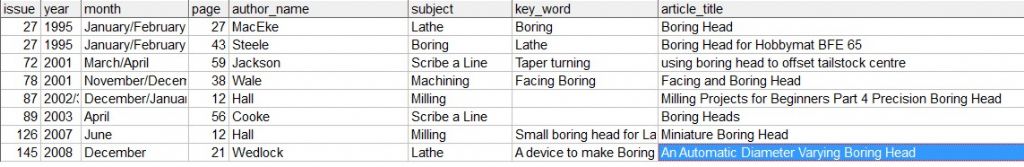

- Miniature Boring bits

- Help Please: IT Not Engineering

- What Did You Do Today 2025

- Harold Halls Workshop Projects book?

- De winton quarry loco 71/4 new member.

- The Perpetual Demise of the Model engineer

- How to sharpen expanding reamer blades & how to adjust them?

- Milling in the lathe – Vertical slide

- Help needed to price a Myford lathe going for sale

- ER25 Collet holder @ 2MT w/ 3/8″ BSW drawbar?

Probably needing to lock it in position when not facing too but things can be spring loaded.

Probably needing to lock it in position when not facing too but things can be spring loaded.