Hello Michael

I have been pondering your quest for a small shaper design. I think one could be made with castings made from epoxy concrete, otherwise known in industry as mineral castings.

The same processes I posted on the write up here on the MEW forum for the Epoxy Worden could be applied to this design.

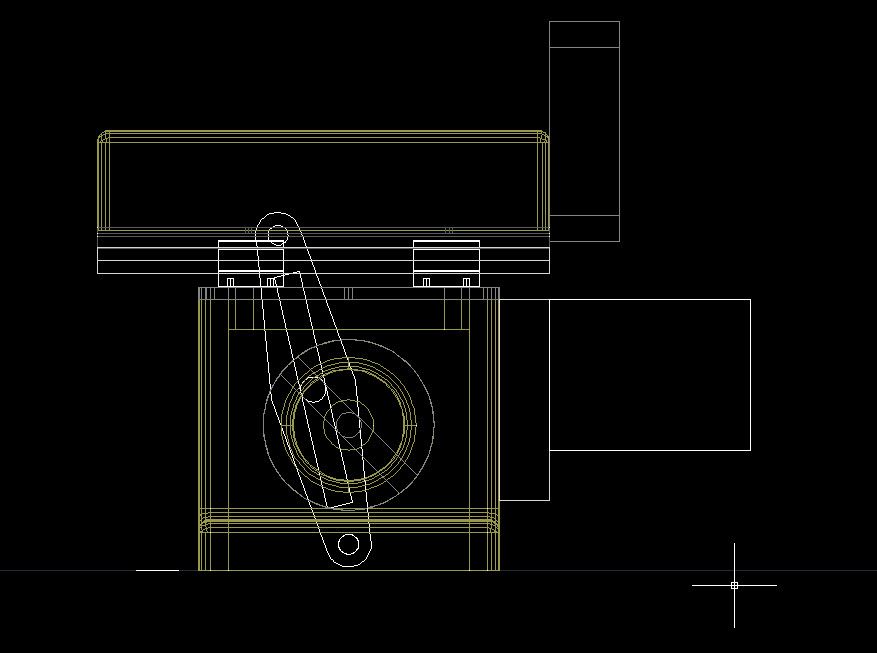

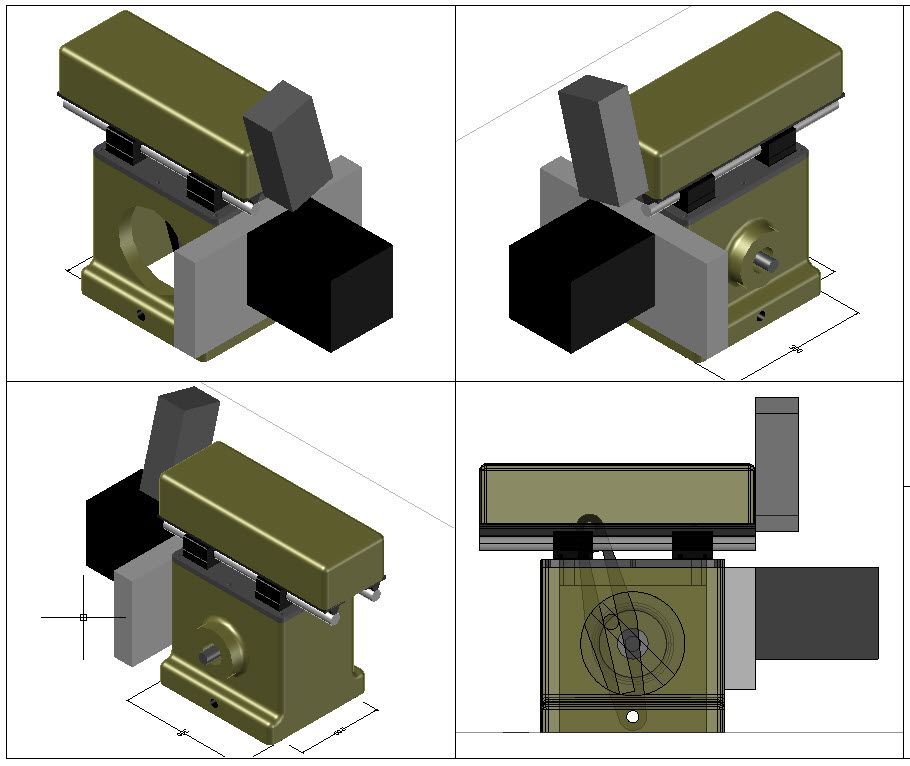

Below are a couple of rough concept sketches of a small machine. The base footprint in as drawn is 200 x 300 Although It can be made smaller if you only want to work on a 100mm cube. (In fact the whole machine needs to be refined), I have only spent a couple of hours on it so far, clearly there is work to do.

The frame and top slide coloured green, and the cross slide coloured mid grey could be epoxy

I have placed the ram on linear shafting and linear bearing blocks for ease of construction, They could be replaced with dovetails for those with the right equipment to make them. They sit on a 12mm metal plate to make attachment and adjustment easier.

the cross slide and tool slide / clapper box are only shown schematically at this stage. They also could use linear bearings or dovetails?

The ram would be driven in the usual way via an adjustable crank arm. It is also shown schematically. It would be great if someone had plans for a full size crank mechanism, it would save a lot of time reinventing the wheel.

Being such a small machine a litre of epoxy should be enough to make it. For those with reasonable woodworking skills the patterns and formwork would be no problem A square metre or two of MDF and a tin of body filler to make the chamfered corners and some sandpaper would suffice.

The various steel components are within the capability of a bench lathe. and ideally a milling machine or a mill drill.

Oh…. and some quality enamel to make it smile.

Regards

John

Edited By John McNamara on 30/10/2013 15:17:03

John McNamara.