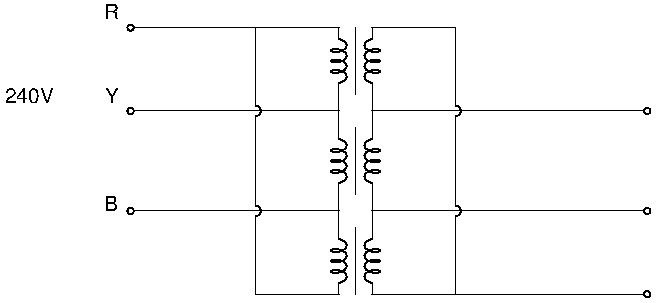

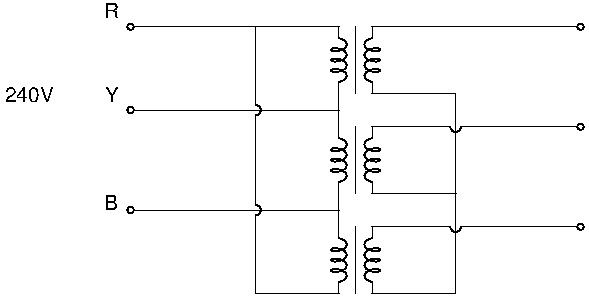

Yes, the transformers will need to be in delta on both sides, and it will be important to get them all the right way around. There is no star point, so it is not floating. The inverter does not have a star point and neither will the delta connected secondaries. I don't think that will matter, even if the load is connected star. I vaguely recall some aspects to do with unbalanced loads and harmonics being affected by connecting star to delta, but hey, that was 37 years back, and I don't think it would be important in this application.

Colin, these inverters are arranged to vary the output voltage linearly with the frequency, at least from the lowest frequency up to 50Hz. Above that, the frequency keeps going up but the voltage does not. So below 50Hz the flux density in the core will be at the design level, same as if it was on the rated voltage and frequency. Above 50Hz the flux density will fall off Same occurs in a motor, which means the available torque will fall off above 50 Hz, but the available power will remain about the same. If the frequency goes too high, you will start to get lots of iron losses, but ordinary motors can typically be run up to what the bearings will stand without any problem. Since it is to be a fixed frequency, all this is moot anyway.

You can do some funny things. I have a ahaper with a 460 Volt delta connected motor. That means that I can't reconnect it to get a lower voltage. I have run it two different ways, one with a step up transformer to double the 230 Volt and apply it to two connections. This works fine but does not self start, You have to kick the pulley at the right moment. In theory I would be getting maybe 2/3 of the rated power. The other way is to just connect it to an ordinary 240 Volt inverter. This means that the motor is run on half its rated voltage, but can (Inverter permitting!) draw up to its rated current. So we would get half the rated power. In practice, that seems to be plenty, if you want to take a quarter of an inch off a slab of steel in a single pass.

If someone decided to test the insulation of the transformer, both between windings and from winding to frame, they would probably apply a 600 Volt Megger. They would have been designed with this in mind, so should be OK connected as above.

John

John Rudd.