3D CAD is a complex program to learn, much like learning a new language and the better CAD systems are difficult and time consuming for a new operator. Once learnt, would never go back to the manual method.

I have been a mechanical draftsmen (draftperson to be politically correct) for 35+ years. Starting work on a drawing board and then Autocad 2D. My introduction to 3D was Pro Engineer. Training for basic level operation took 1 week full time at a training centre. 3 or 4 weeks later I returned to the centre for another week of training for the advanced level modelling course. Then again later for an advanced drawing course. It was estimated that it would take 3 to 6 months for a compitent draftsman to be as efficient producing drawings than he had been doing them by hand. After this time it was far quicker to produce drawings than before. Especially if it was only to make midifications to and existing drawing. Modern CAD system are much more use friendly but still take a while to master.

Accurate dimensions on hand made drawings has to be calculated. Overall lengths of multiple parts had to be added together, sometimes with mistakes, To eliminate mistakes before production, the drawings were sent to a second person for checking. CAD drawings are extremely accurate and therefore often do not need to be checked for correct dimensions. The top line CAD systems can automaticall check for interference between parts. They can also calculate the mass and centre of gravity. Some also have finite element analysis modules to calculate stresses.

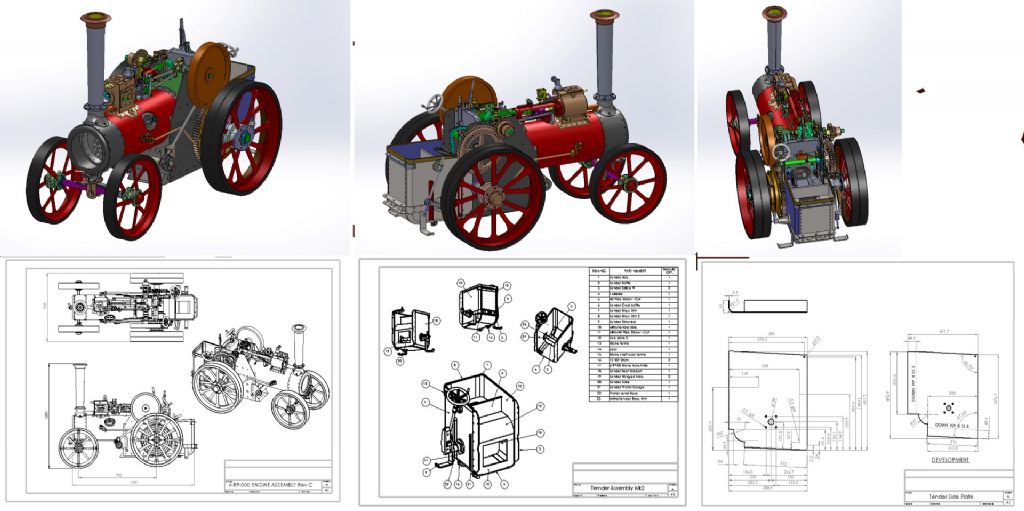

As projects get more complex there is a high risk of making mistakes. Parts which have to be modified or scrapped. The traction engine which I am building has many parts and everything is modelled on the computer before I commence machining and wasting time and money.

After the model is complete, assembly and individual part drawings can bequickly produced. Dimensions for parts can be automatically (or manually) added to the drawings. When any change to the model is made, all of the associated drawings are automatically updated. Even possible to change the model by changing dimensions on the drawings. Assembly drawings can be automatically populated with item numbers and a Bill of Materials.

I use Solidworks which has a sheetmetal module which can create layout drawings of bent plates in the flat state with position of the bend line for pressing.

Paul.