Posted by SillyOldDuffer on 13/05/2017 09:43:54:

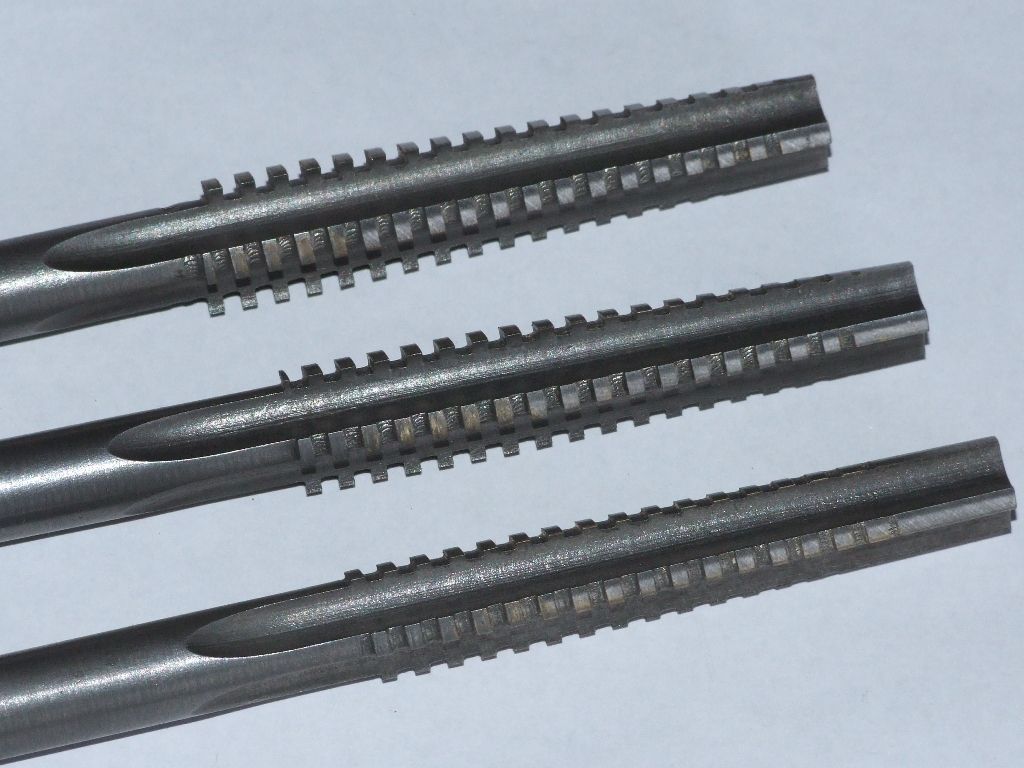

It occurred to me that the amount of burring on the thread would be reduced if I cut the taper before cutting the thread. Apart from light deburring I didn't clean up my Mk1 tap at all. That's worth doing too especially if I'm in a beauty competition with Andrew's professional efforts.

Michael's comment about heating for 40 minutes per inch for full hardening has got me thinking. That's much longer than I heated the tap. A happy accident perhaps. Would leaving the core of the tap unhardened compared with the teeth make it tougher?

Playing with screw-cutting has added several new toys to my wish-list. 5C collet chuck; quick-change tool-post; carbide threading tool with inserts; and now a small ball cutter as well. Fortunately I already own a Dremel and needle files…

Since I have a secondhand electric furnace I usually leave silver steel/gauge plate to soak at hardening temperature for about an hour per 1" of thickness. However, the single most important factor in hardening is the quench. I normally use brine. Experiment (aka I got it wrong the first time) has shown that simply plunging into the brine results in a hardness of around 45Rc. To get full hardness, >65Rc, you need to agitate the part. And I mean agitate, don't just stir it around, think cat on a hot tin roof!

I have a proper hardness tester but haven't got to grips with it yet. Currently I use these files to assess hardness:

It took me hours to clean up all the burrs on the taps after fluting but before hardening and grinding.

As for the wish list:

Collet chuck:  I've got a Crawford multisize collet chuck, which I use for all turning up to 1½", after that I use the 4-jaw. I very seldom use the 3-jaw chuck.

I've got a Crawford multisize collet chuck, which I use for all turning up to 1½", after that I use the 4-jaw. I very seldom use the 3-jaw chuck.

Quick-change toolpost:  Way back I bought a secondhand Dickson toolpost and holders. But I've never fitted it; it still sits on the shelf. Reasons for not fitting are that it wouldn't be as rigid as the existing 4-way toolpost. My current toolpost has an indexing ring underneath, which is surprisingly useful. I don't really want to lose that facility. I use very few tools, probably 90+% of my turning is done with four tools. Specials are just that, specials; and I wouldn't keep them in a holder even if I was using the QC toolpost. I don't worry overly about setting tool height either. I just line it up by eye with a centre in the tailstock. Granted I tend to machine larger diameters, where it is less critical, but I just don't see the need to sweat over the last few thou. It's interesting to note that a very common phrase on the forum is that as amateurs/hobbyists we're not in a hurry and therefore don't need to worry about industrial techniques/shortcuts, yet QC toolposts are just that but seem to be 'essential'.

Way back I bought a secondhand Dickson toolpost and holders. But I've never fitted it; it still sits on the shelf. Reasons for not fitting are that it wouldn't be as rigid as the existing 4-way toolpost. My current toolpost has an indexing ring underneath, which is surprisingly useful. I don't really want to lose that facility. I use very few tools, probably 90+% of my turning is done with four tools. Specials are just that, specials; and I wouldn't keep them in a holder even if I was using the QC toolpost. I don't worry overly about setting tool height either. I just line it up by eye with a centre in the tailstock. Granted I tend to machine larger diameters, where it is less critical, but I just don't see the need to sweat over the last few thou. It's interesting to note that a very common phrase on the forum is that as amateurs/hobbyists we're not in a hurry and therefore don't need to worry about industrial techniques/shortcuts, yet QC toolposts are just that but seem to be 'essential'.

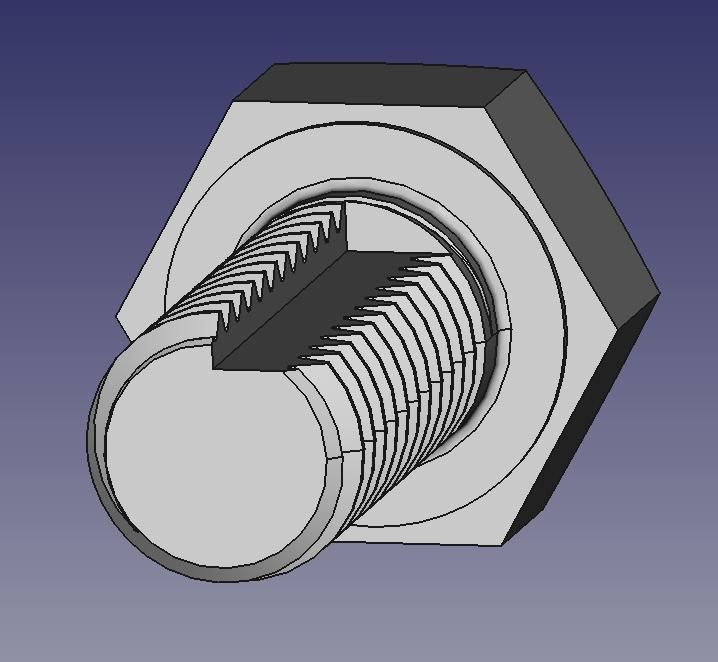

Insert threading:  I use these as standard for most threads. I use HSS for specials. Being square thread the taps shown previously were cut with a HSS toolbit.

I use these as standard for most threads. I use HSS for specials. Being square thread the taps shown previously were cut with a HSS toolbit.

Ballnose cutter:  I've got a good selection, as I use them a lot on the CNC mill

I've got a good selection, as I use them a lot on the CNC mill

I have several sets of Vallorbe needle files, but no Dremel……….

Andrew

SillyOldDuffer.