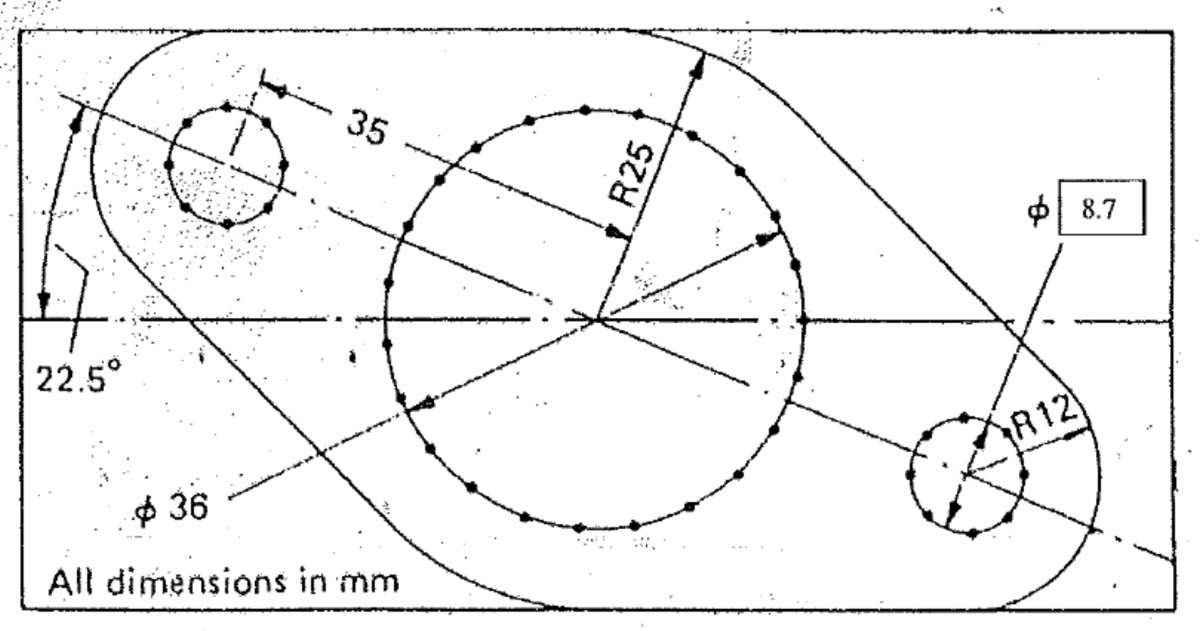

I think it’s probable that this part was hand drawn and expected to be made out of 50mm wide bar stock by someone wanting to keep machining of the flat sides down to a minimum for whatever reason, possibly cost in a factory. …

Martin C

I agree Martin is probably right. So also is Jason – the draughtsman made a mistake!

Just possibly though, maybe the drawing was tilted as an exercise just to extend the students skills, and not worked out fully. The creator didn’t know his example would be tested by a CAD package that highlights issues humans might miss.

In my innocence, I would draw this with the centre line horizontal and do the sums later as necessary to make the item from bar stock. Martin is smarter than me, spotting the thing is essentially 50mm. Actually I make the distance between parallels to be 49.6694mm. Not investigated yet why they aren’t exactly 50mm apart, in accord with the drawings largest diameter:

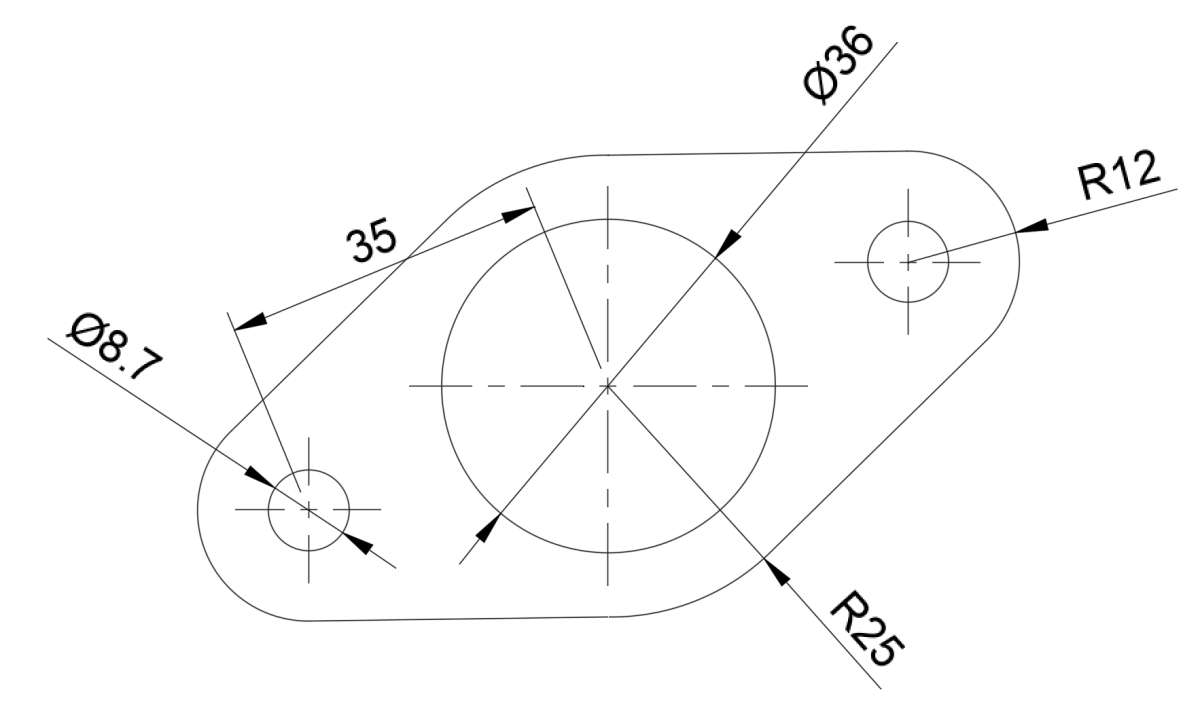

Anyway, to get the tilted version, I simply rotated the whole drawing by 22.5°. Rotations are trivial in most CAD applications, but hard work on a mechanical drawing board! But rotating by 22.5° reveals that the lower straight line is off-horizontal by 0.696°:

I no longer have F360, discarded in favour of SolidEdge, because AutoCAD altered the licence conditions and are able to enforce new rules because the product has to phone home periodically. SolidEdge is harder to learn, but it runs locally. My examples are QCAD; no problem, Jason has answered John’s original F360 question.

Does this drawing being slightly faulty matter? Not when making a few parts from it in my workshop, where only the hole sizes and coordinates are important, and could be gently bodged if need be. More serious if the part is mass-produced as an interchangeable spare. Fireworks if an engine builder orders 100,000 of them, and finds they don’t quite fit into a tight space on his engine…

Dave

blowlamp.

Thanks guys, I haven’t been as clear as I should have. I can get the reference line to appear in the sketch as Jason has displayed in the post above this, it’s in the final drawing page I’m wanting it to display. I suspect that it’s not possible because it’s not needed to create the part as such, but I thought I should check.

Thanks guys, I haven’t been as clear as I should have. I can get the reference line to appear in the sketch as Jason has displayed in the post above this, it’s in the final drawing page I’m wanting it to display. I suspect that it’s not possible because it’s not needed to create the part as such, but I thought I should check.