Comments.

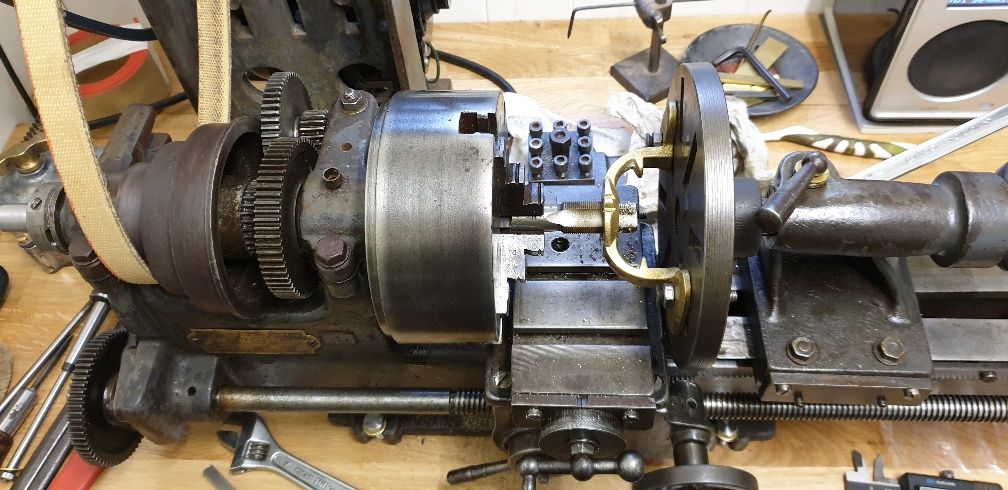

The Myford M Series have dovetail beds, so wear on the dovetails may be less easy to recover, than on the flat top of the bed.

So your check with a straight edge needs to include the dovetails, (The rear dovetail may be even more difficult! ) as well as the flat top of the bed.

There will be backlash between the pinion and the rack. This is the normal method of moving the saddle, manually. Which is what you would do most of the time. In any case it is quicker than winding along with the Leadscrew, which will need 8 turns to advance the Saddle by an inch

The half nuts will be engaged with the Leadscrew if you wish to set up the change gears to provide a power feed for turning, to cut screwthreads, or to advance the Saddle by a measured distance.

For what my advice is worth, I would check one thing at a time, staring with the rear dovetail; then the front dovetail, and then the flat top of the bed, correcting the wear in each feature.

But remember that you will have difficulty putting on metal, if you remove too much. So proceed VERY carefully.

My first purchases would be a tin of Micrometer blue, and a good 12 " straight edge, plus laying in a good stock of clean rag, and Swarfega, with which to clean my. hands.

SLOWLY SLOWLY CATCHEE MONKEE!

When you happy with the bed, then clamp an accurate bar in the chuck, (1/2" minimum dia Silver Steel possibly ) and check that the Headstock is aligned with the bed. Unless your lathe is a very early one with a cast in Headstock, it should be possible to correct any misalignment by slackeinng the 1/4 BSF nuts that hold the Headstock to the bed.

Once that has been done, fit centres, and with a properly centre drilled bar and starting checking the Tailstock for alignment in first the horizontal plane, and then in the vertical plane. Adjusting for Zero deflection horizontally should be fairly easy, using the 1/4 BSW adjuster on the far side of the Tailstock. Recheck after locking with the nut!

If the centres are out vertically, you may have to scrape the underside of the Tailstock to bring the centres into alignment. If the tailstock centre is low, you will need to find some means of adding shims.

Again,BE CAREFUL, not to make matters worse! You do want a Tailstock barrel that points towards the sky, or the floor.

Either way, you will need to check that when the vertical alignment is correct, that the horizontal has not been changed since first set up.

Once you have got the lathe into alignment with as little backlash as possible, you should have a useable, mand useful, machine, even if it has foibles compared to a modern machine.

Howard

Chris V.

….. slidewayservices.co.uk of Nuneaton seem to offer regrinding services. A call maybe? What would it be worth to get it done? I'm guessing on a chinese mini lathe…. not so, but a lathe passed down from family generations, with some sentimental value… ?? This is purely hypothetical, and may well not apply to you Chris, but got to be worth a call?

….. slidewayservices.co.uk of Nuneaton seem to offer regrinding services. A call maybe? What would it be worth to get it done? I'm guessing on a chinese mini lathe…. not so, but a lathe passed down from family generations, with some sentimental value… ?? This is purely hypothetical, and may well not apply to you Chris, but got to be worth a call?