How much wear is worn out? It varies. But Myford literature specifies that .005" of bed wear is enough to need the bed regrinding. So your half a millimetre is probably cause for concern. However, you do need to measure exactly how much wear is there, either with a straight edge and feelers, or a depth micrometer if there is an unworn section next to it, or by mounting a dial indictor on a long extension from the saddle, then running the saddle back and forth on the relatively unworn tailstock end of the bed while tracking the dial indicator on the worn section at the headstock end.

Noisy headstock is indicative of perhaps headstock bearings worn out, something that will also cause misalignment and tapered turning.

If you put your lathe back together and sell it for the 1000 pounds you paid for it, then put together the 1200 pounds bed regrind price and the cost of possible headstock bearings which can be as much again I hear, you are on the way to having enough money to buy a better lathe. Plus you have to figure on a lathe that has worn out its bed and bearings, there will be other worn out things that need money spending on too. EG, tail stock base and barrel, tops slide ways, cross slide ways, leadscrew (both main and the cross slide) , half nuts, drive gears etc etc.

+1 on really sit down and list out all the actual expenses and inspect every tiny part of the lathe to determine just what those expenses will be. Then compare with the cost of selling the lathe for what you can get and buying something ready to use. Beware of putting serious money into old machinery that ends up needing more, and more and more every time you look at the next stage. It's a slippery slope!

Edited By Hopper on 02/02/2017 07:45:12

Edited By Hopper on 02/02/2017 07:45:54

thaiguzzi.

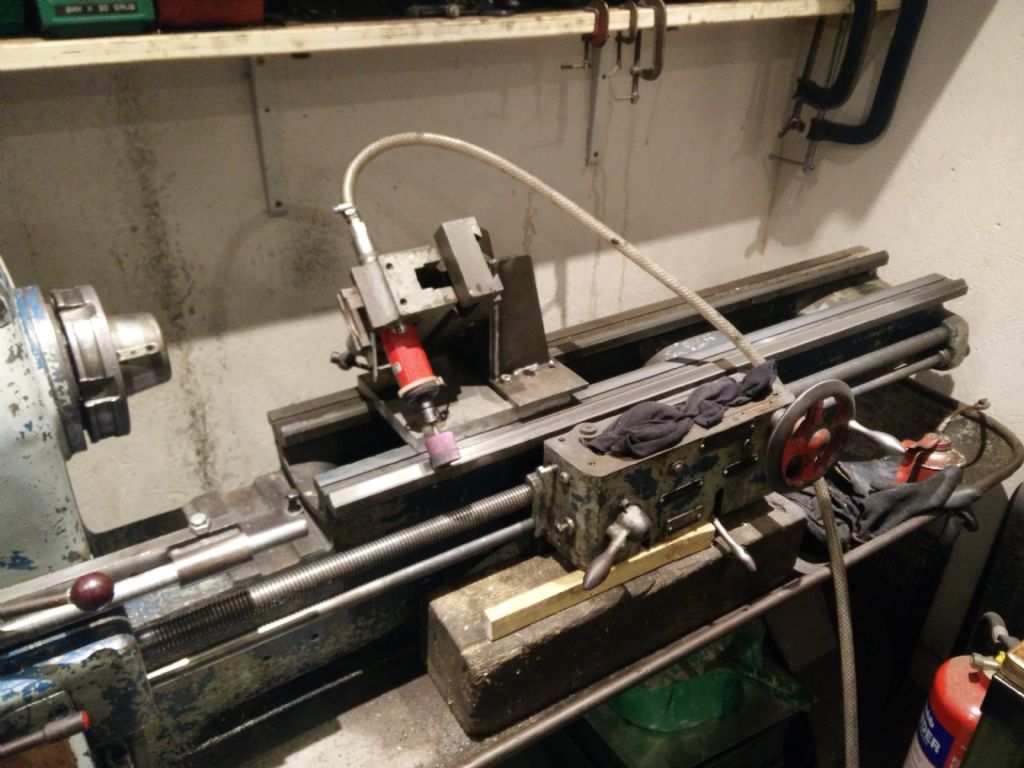

![img_20171102_212643[1].jpg img_20171102_212643[1].jpg](/wp-content/uploads/sites/4/images/member_albums/172610/788548.jpg)

![img_20171029_184406[1].jpg img_20171029_184406[1].jpg](/wp-content/uploads/sites/4/images/member_albums/172610/788546.jpg)