Posted by peak4 on 26/10/2021 22:05:24:

Re filing guides, I was watching this video earlier; the whole thing is quite interesting, but the bit from 2:20 in might be applicable to your requirements. If I've done this correctly, it might even start in the right place.

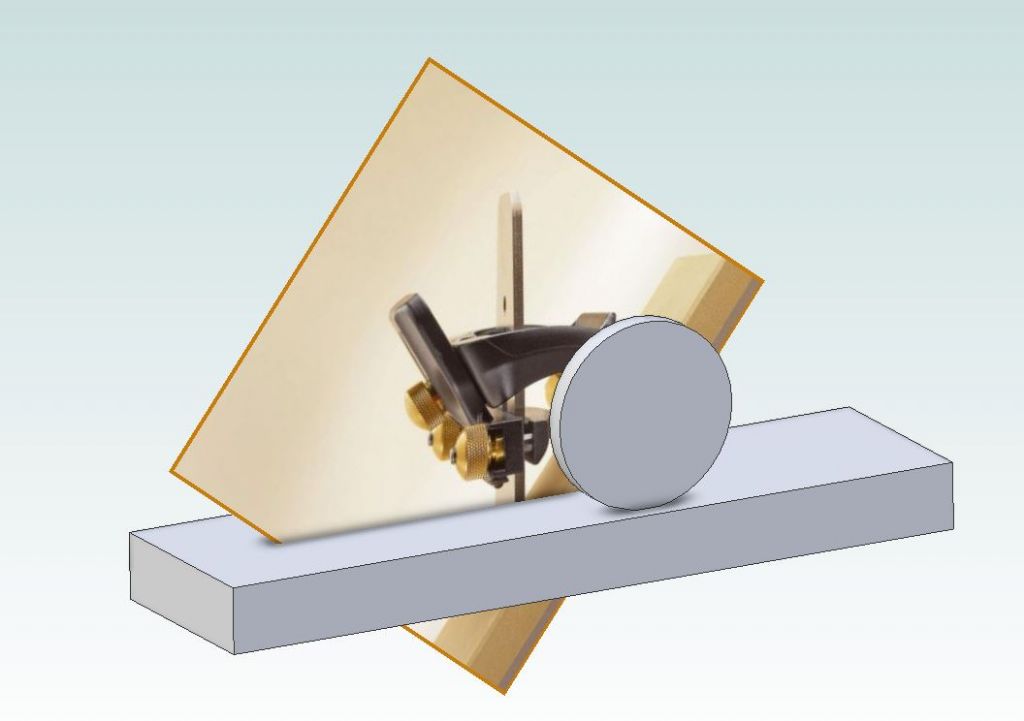

Something like this gizmo, a square, and a micrometer, should get you excellent accuracy.

Thanks, I enjoyed that video – almost rather meditative…

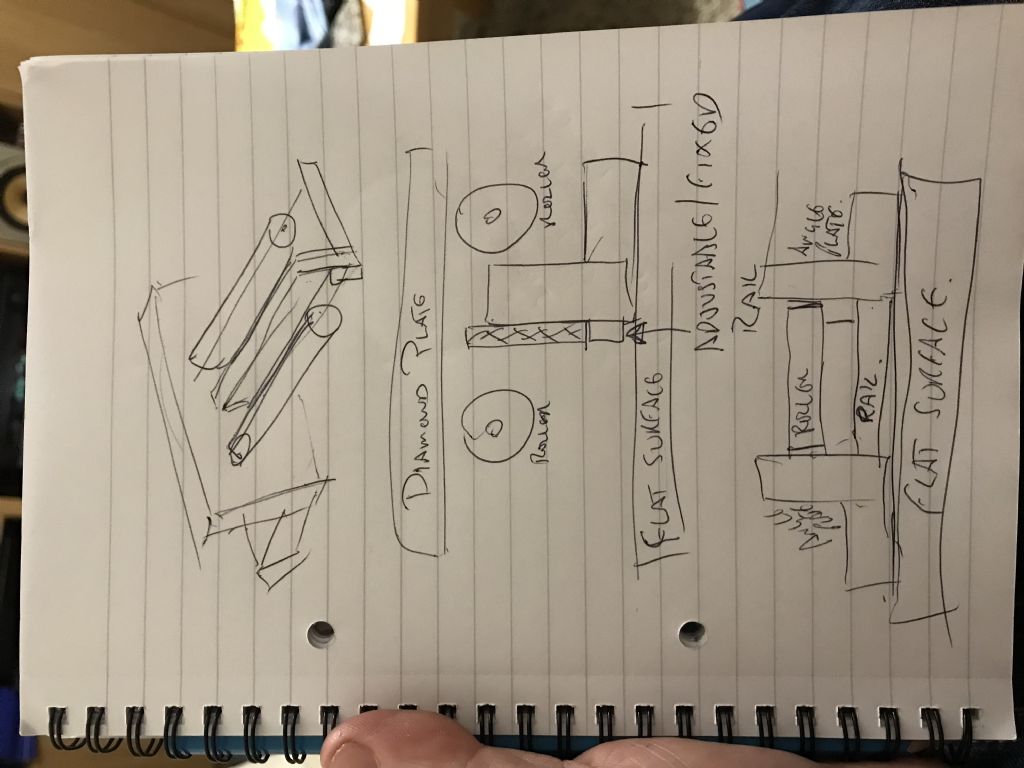

But no way am I letting carbide go anywhere near my highly treasured hand files! I don't have any old ones. And I'm not sure I much want to buy some new ones just to trash on some carbide. In principle rollers sound much more sensible, no?

Fwiw, I am located in Oxfordshire.

Questions:

1. Have any of you good folks tried the "Boeshield T-9" corrosion protector that he raves about?

2. What is that black pen he his using for his rough measurements? I need to find something better than my fine black Sharpie marker pens which keep drying out. FWIW, sometimes I have used a fine white pen which I find works better that black in some lighting conditions.

3. I have never come across Layout Blue. Who often & when would you use it? It looks like a really good idea for making scriber lines 'pop' (which unless it is a mirror finish I find really hard to see). Is there a reason why it has to be blue, or is that just a convention? I like the idea of a brush in the cap (no paintbrush to clear) Is Dykem's Steel Blue Layout Fluid the best?

But all of which is rather a long way from my original question:

Machinery not withstanding, is there really no good way to make an accurate 90° grind using a diamond whetstone?

[If all else fails I was thinking of possibly using the side of a large V-bock to which I had stuck a layer of protective, low friction film/paper (e.g. waxed paper?) to create a vertical surface, and then running my steels up and down the side of it as I grind one edge of the steel… ]

Edited By John Smith 47 on 27/10/2021 00:42:09

John Smith 47.