Ok Michael, some info on the motor and Drive..

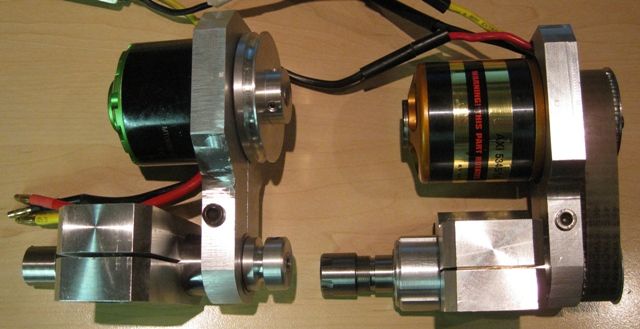

The Motor is an AXI ( East European) brushless 3 phase Model aircraft motor – 280 RPM/Volt. It is capable of 2.5KW output in an aircraft, sort of 40V in at 100 amps…But not in this application! The max speed of the Grinder results in no more than 4 amps drawn from the DC supply.

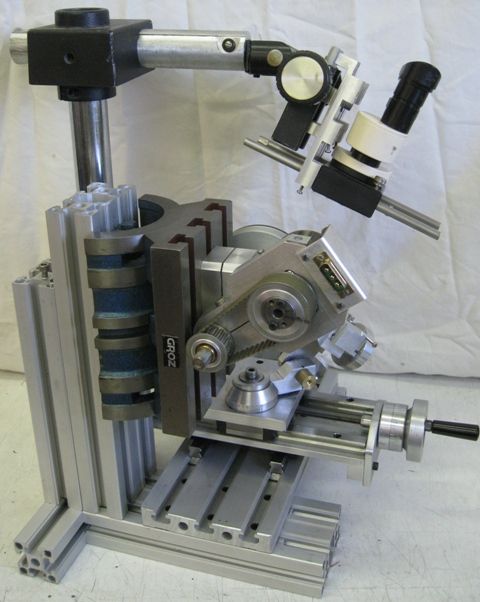

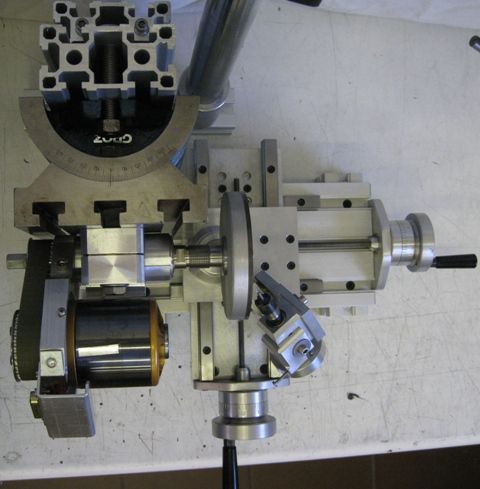

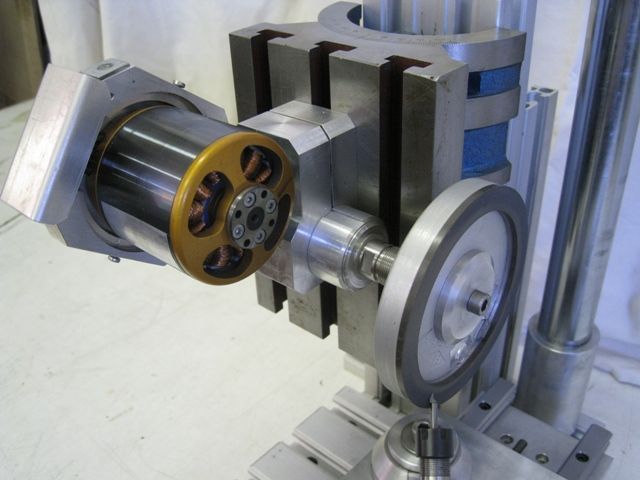

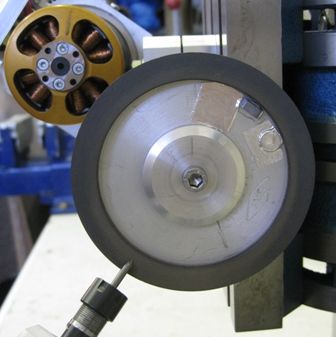

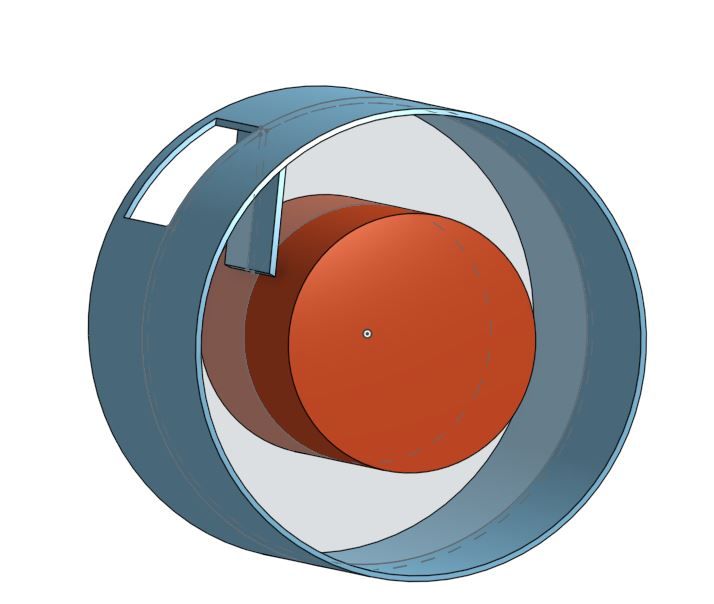

The motor is about 52mm diameter and 60mm long, and is of the 'outrunner' type, ie, the outer casing, containing the magnets, rotates. This gives high torque capability.

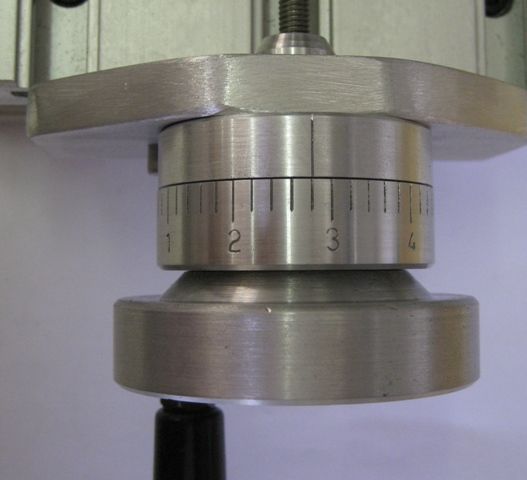

The DC supply, run from the 220VAC mains, can give 8 amps at voltage from 10 volts up to 36volts. This is fed to a brushless motor electronic speed controller (ESC). This connects to the three phases of the motor. Since the ESC requires a Pulse Width Modulated input to control the motor speed, this is provided by a simple 555 timer, generating a pulse every 20 milliseconds, the pulse width being variable between 1 milliseconds and 2 milliseconds ( max speed). The motor has best performance when the PWM value is at 2 milliseconds, so normally I just set it to 2ms, and vary the motor speed using the variable voltage supply. Actually, its the ESC that works best, least losses, when the PWM value is max, so better to give max and vary the DC voltage supply.

This PWM signal is the signal that in a model plane would normally come from the radio control receiver module.

At 36volts the motor RPM is around 10000 RPM. The pulley ratio between motor and spindle is 1.25, giving a spindle RPM of around 12600 RPM, more than enough!

That all there is to it. These motors make very attractive drive units – they are inexpensive, the larger ones have very good torque capability, and the ESC is likewise inexpensive. A source of PWM signal, if you are not up to fiddling with 555's or the like, is, from the same model Shop, a model servo tester – a little box, with a control knob on it, giving said pulse out.

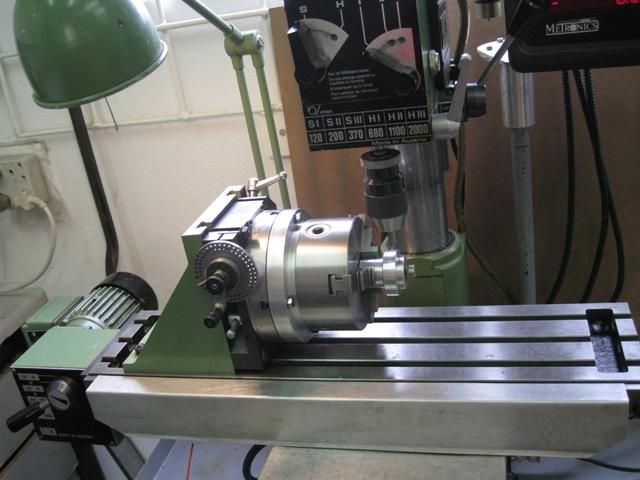

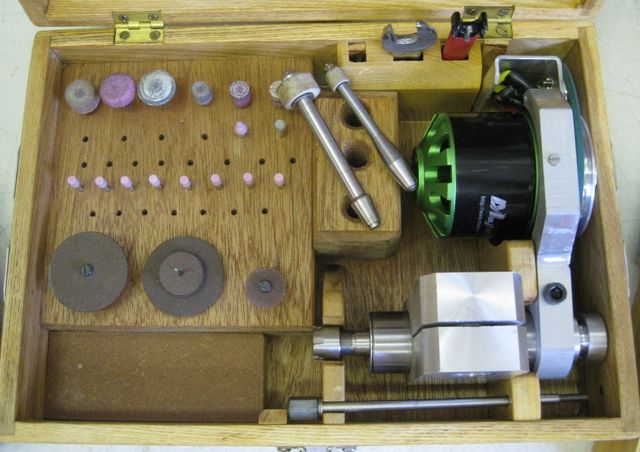

I have used the same concept on the toolpost grinders, the Hi-speed spindle of my CNC PCB engraver, and on the Sensitive Hi-Speed drill. The one variable power supply / PWM signal generator is used on each machine when required.

Will try make a post of these as well…

Regards

Joe

Gene Pavlovsky.