The machine is up and running as Myford intended, power feed and all. I got involved because I like myfords and being an owner of a nice VMC fancied a good look in to what makes the bigger brother here tick, and as I'm sure Clogs will agree – I got more than I bargained for! It is in no way similar to the VMC, my VMC doesn't even have any buttons or switches. This VMF is a fantastic bit of electrical engineering – although I'm sure its all pretty standard stuff to an electrician, it wooed me.

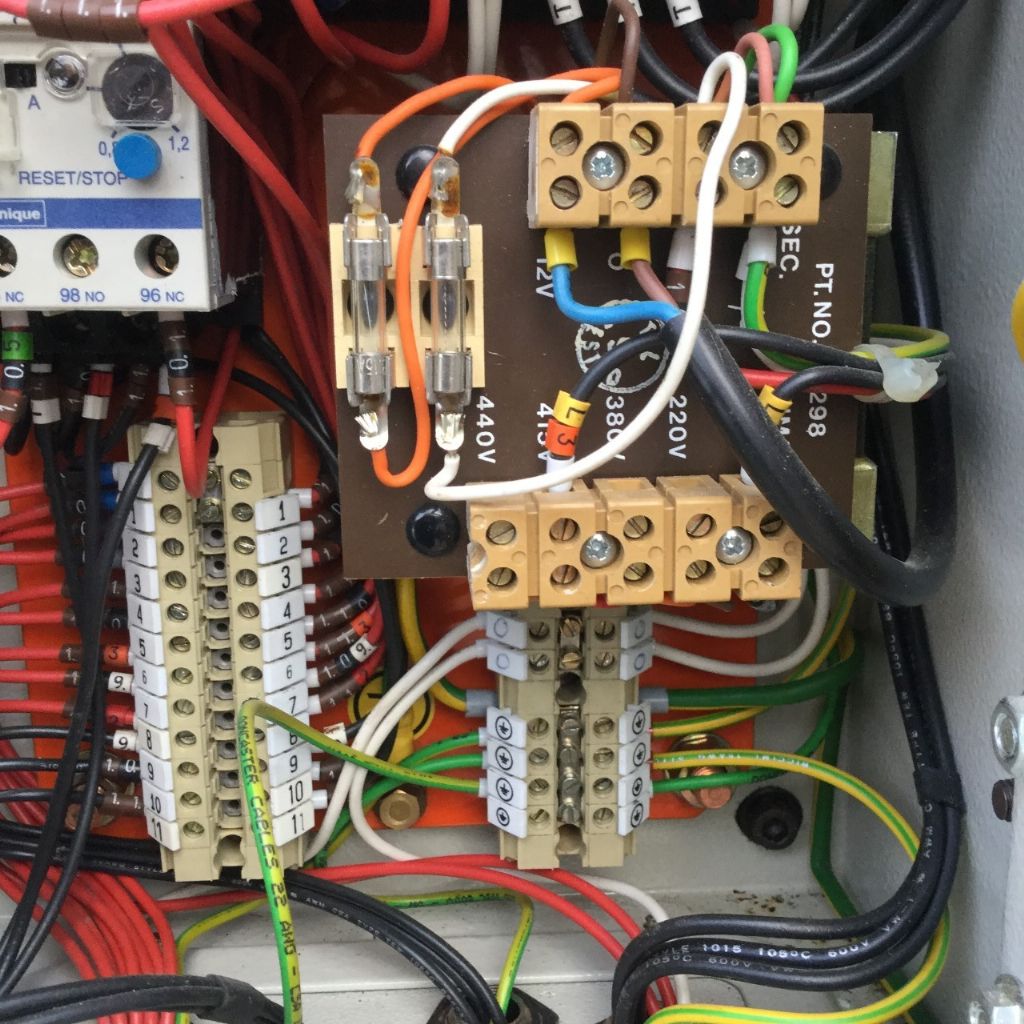

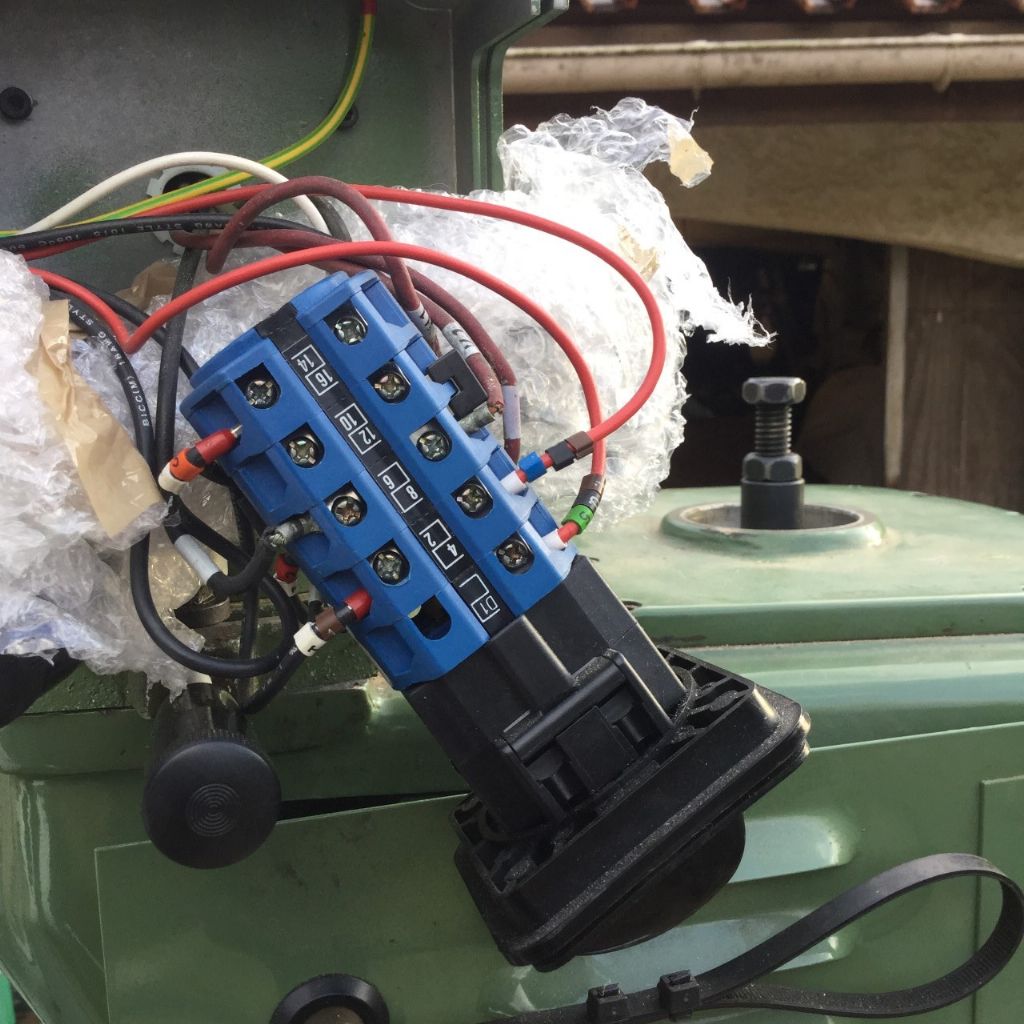

The cabinet on the VMF is quite advanced. The spindle is a single direction, dual speed type. Speed is handled in a traditional fashion switching wye/delta via a rotary switch on the milling head near the motor. This rotatry switch has a no volt release which is supplied, via an overload, with the cabinets control voltage (110v).

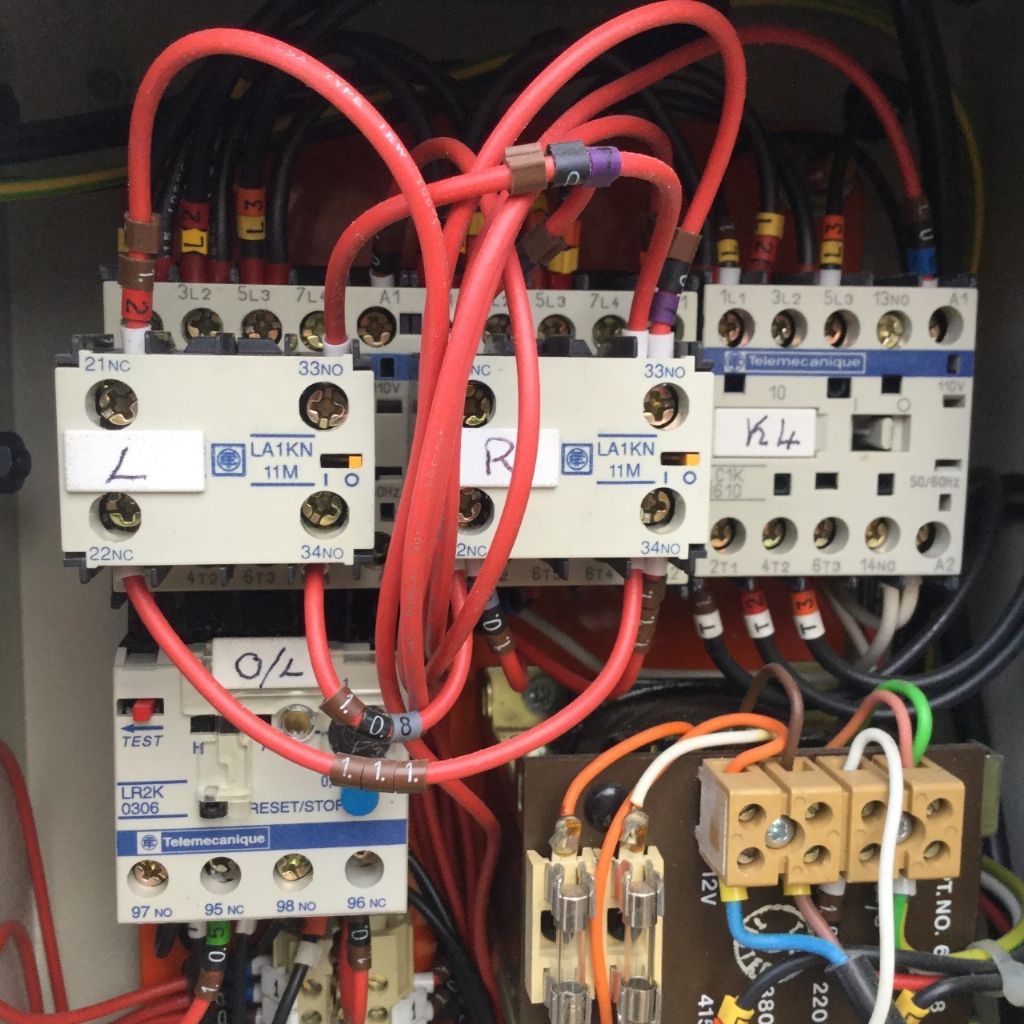

The pair of contactors in the cabinet which have aux modules mounted on top is actually one double din contactor which is handling the left stop right for the table traverse. The left and right buttons are momentary N/O and pressing them latches the contactor via the limit switches on the table which are N/C so the contactors drop out when pressed.

It was a bit of a challenge, we went through everything give or take almost nothing. Trying to work out what went where and how everything was intended. I worked how how the rotary switch internals could/should link up in position 1 and 2 to give both speeds given the position of 6 motor wires, the 3 phases and a couple of bridges and it was indeed setup in a way that could switch wye delta (no manufacturers information on this switch, it was a special). I then noticed, that the wire in terminal 4, shouldn't be there, it would probably want to be over the other side in D2, or at an unmarked terminal nearby. This error was effectively connecting the solenoid of the motor contactor to a phase on the motor – and catch 22, it was never going to start (although putting 440v to a 120v contactor probably wouldnt end well)

Once this ONE wire was moved to the correct position – the whole dam thing sprang to life, finding that one wire, was quite literally, a needle in a bloody hay stack but we got there, and I think secretly, we both enjoyed it.

Neither of us are really electricians  – but we're both quite nifty at it now! We solved this about a month ago, but it probably took over a month of emails back and forth with us both spending a little time here and there to progress thing.

– but we're both quite nifty at it now! We solved this about a month ago, but it probably took over a month of emails back and forth with us both spending a little time here and there to progress thing.

All the best to Clogs and his VMF, hopefully, I'll get first dibs if he ever sells it

Edited By Russ B on 19/12/2016 14:19:21

Vinny Rogers.