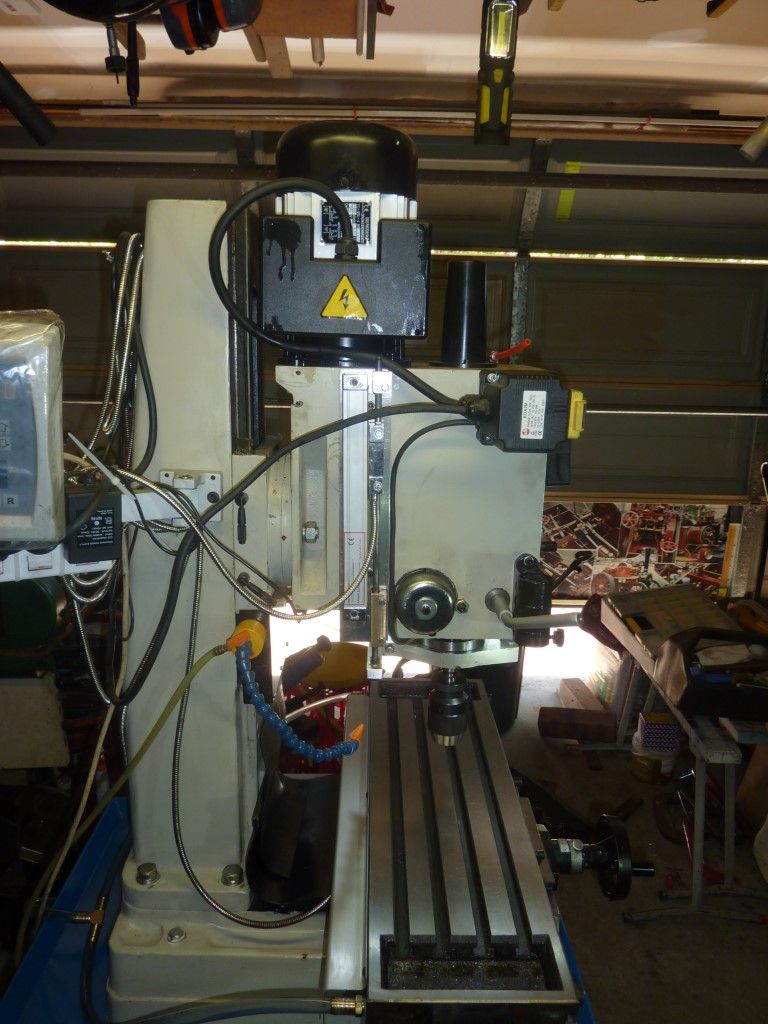

You will have problems if run the Luxs faster than they come 1250rpm.

If you go back some years about 14 there was a US reseller modifying these heads, quills and spindle to accept bigger better beefier bearings that then could handle 2500rpm.

Has happened a few times on mine even with the best SKF bearings fitted they get hot. Extended use may see spindle slow down – its seizing and thats only at 1250rpm.

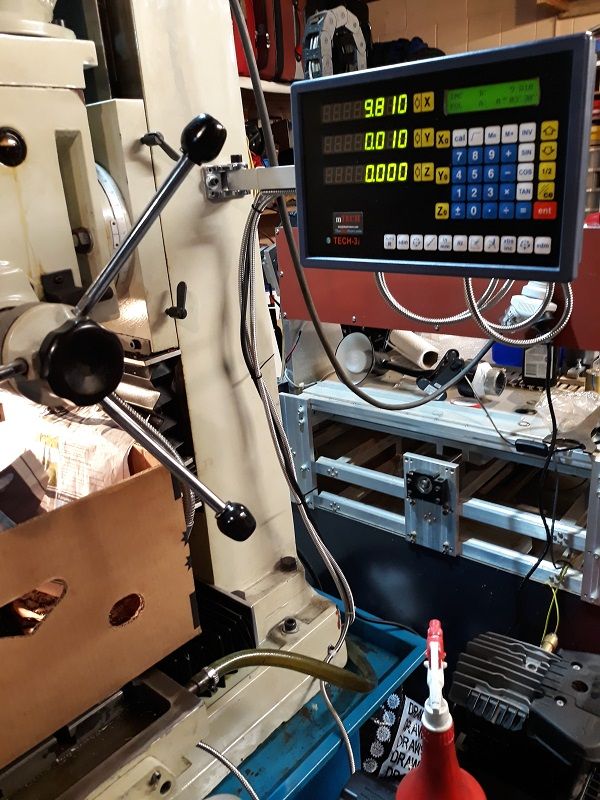

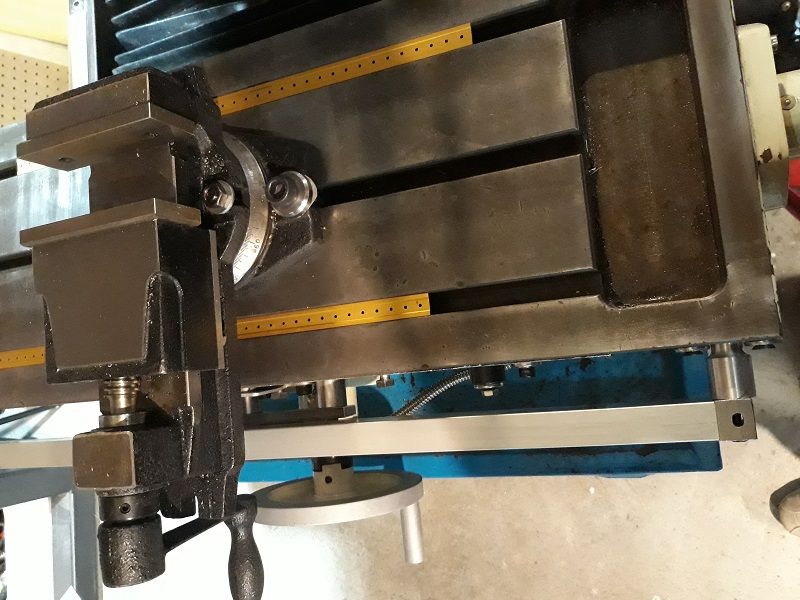

Quite easy to get a C type glass scale on either side of the head, done it 13 yrs ago positioned near where Pauls is, credit where its due. Also needs the pin sizing in to reduce quill rotation.

Needs a strip down twice a year to clean up the dust on the glass.

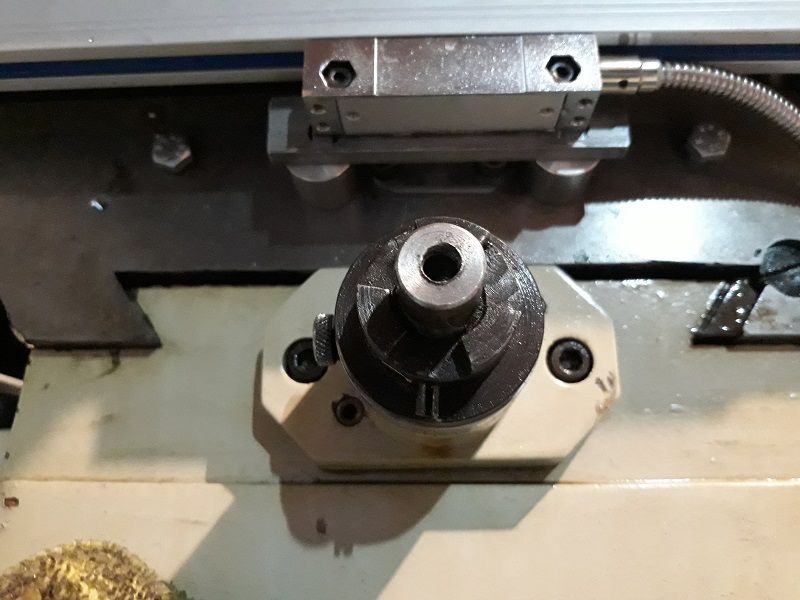

Spindle locks in same place as mine, pushes quill to the right and back when tightened up.

Hydraulic 68 plenty good enough from Smith and Allen about £17 delivered for 5 ltrs, changed mine for sealed SKF bearings 8 yrs ago, the oil dont froth like the stuff that comes with it and if its good enough for Harrison head stocks its more than good enough for chinese.

Nothing will really quieten them down without sacrificing power. Even if you run a heavy tar like oil its viscosity will change to become much like all other thinner oils when it warms up.

Neil i wouldnt be putting X axis there you cant use any stops, poweer feed (trips 2 and stops) and cant use a rotary table with dividing plates or even use the must have bed locks without socket, extention and bar on tap.

Power feed packed up on mine yesterday mid job didnt want to spend any more on it, as good as scrap 8 yrs ago. Turned 3pm ordered from Goodwin saves me a trip to Brum or Tamworth, delivered by 10.15am next day. Shame could have been £360 put towards something decent now may be able to use it as a knee lift or Y axis motor.

Neil Lickfold.