Seems good reasoning Jason, mine has the DRO.

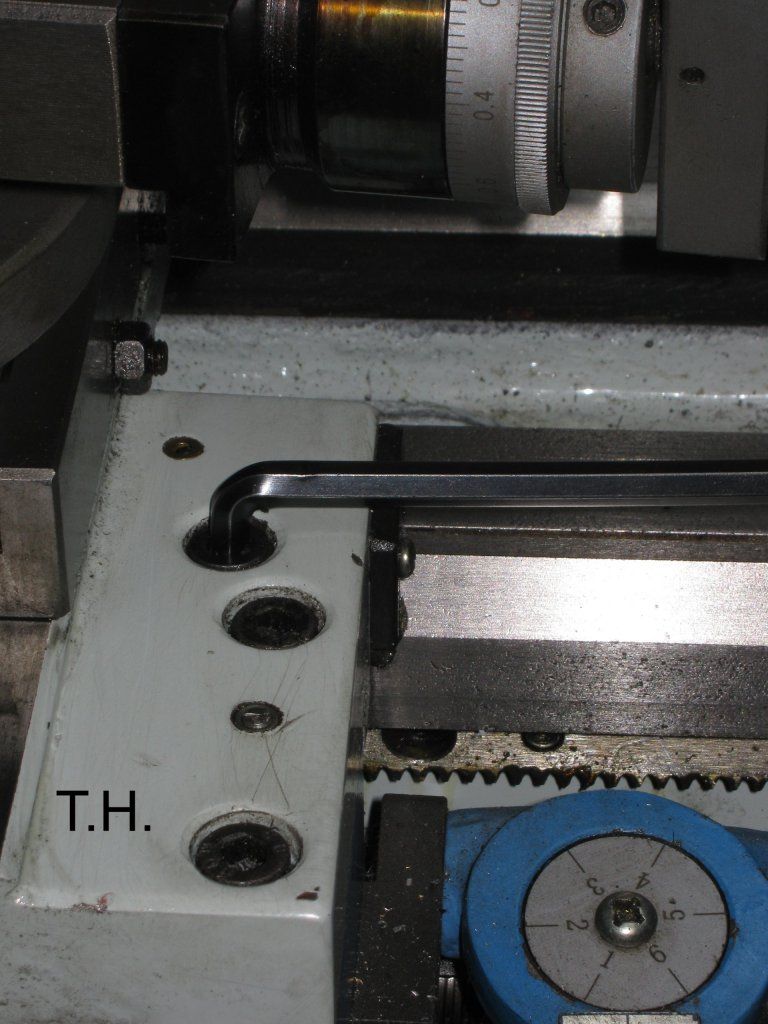

Thanks for the pic Thor, mine looks much the same but with the DRO on the right of the cross slide. In in the manual it indicates the locking screw on the left side.

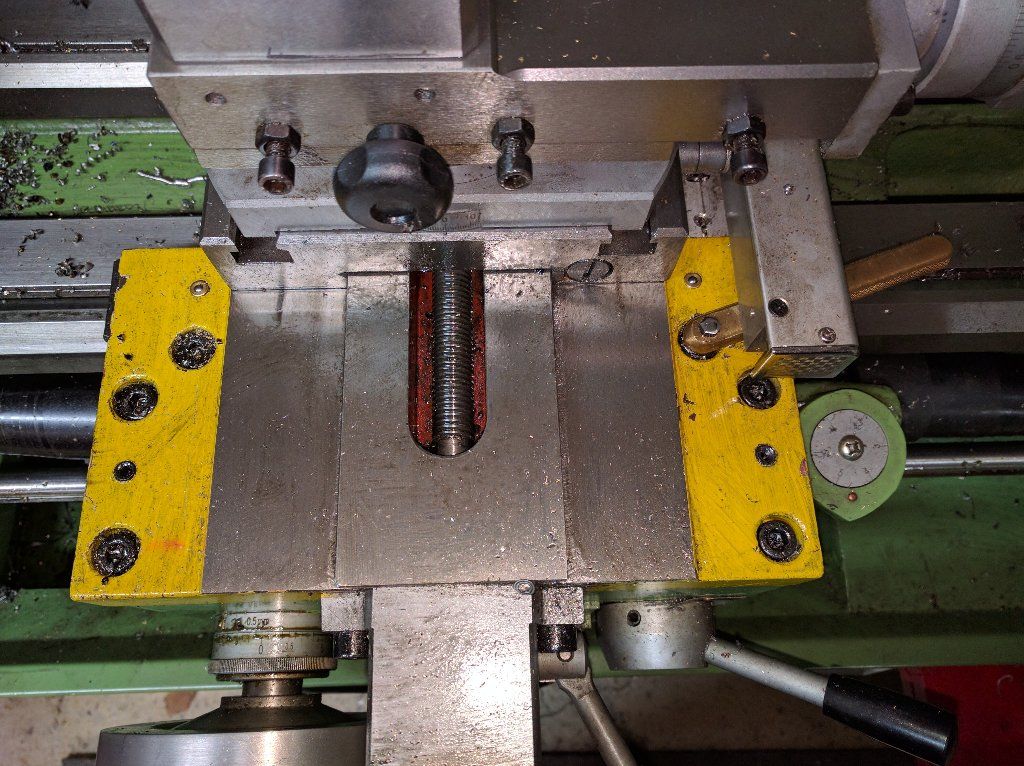

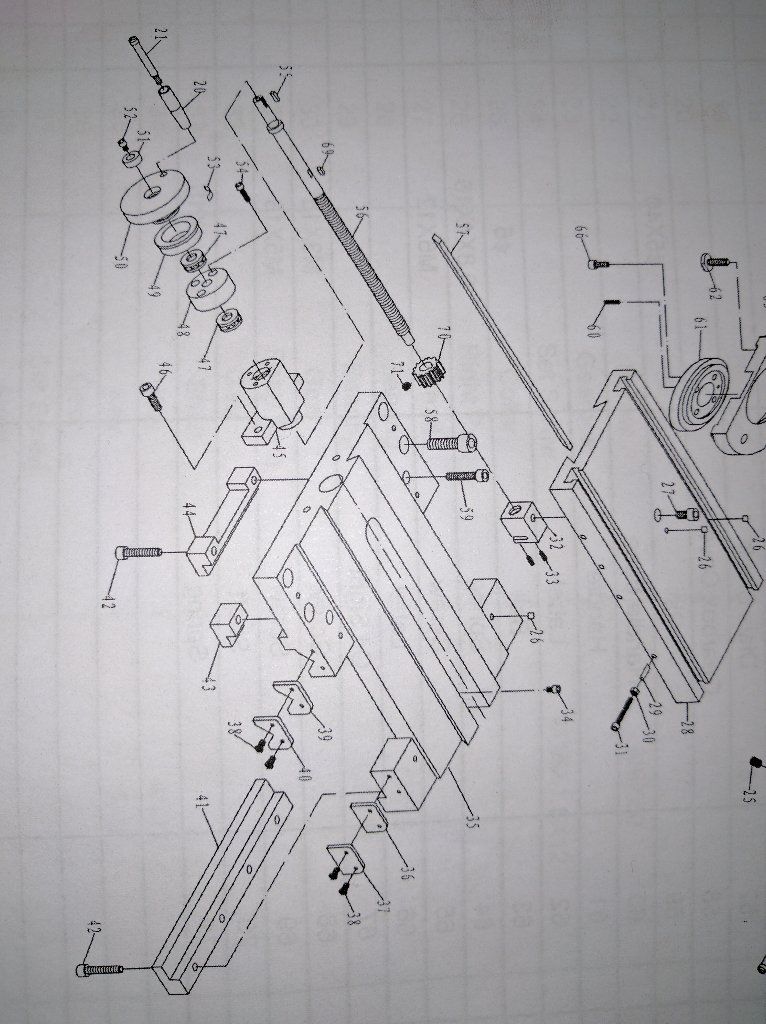

Having another look at mine the two screws outer screws on each side appear to bolt the carriage to the apron, sticking a finger under the carriage the single inner ones screw into a block that locates under the slide, I assume to stop carriage lift. As they are fully tight I guess that the blocks are machined to give just the right running clearance.

I suppose I could remove one of the blocks and machine a bit off so that it locks when full tightened but that would probably mean that you will have to carefully set it when not locked so that there is not too much play causing lift, even then it could move with vibration, I don't think I will bother, as far as I am aware I have not actually had a problem with carriage moving when doing a face cut.

Other than that I love it, a big improvement on my Clarke lathe I had previously, the biggest joy for me as silly as it sounds is having the carriage on a rack rather than furious winding of the power feed screw to move the carriage back and forth all the time, plus the DRO which is excellent

Thanks guys for feedback,

Bill D.

mechman48.