I mentioned in another thread that I was purchasing a small 3 jaw chuck to fit my Flexispeed lathe. Here it is with a 14 x1 mm thread: No mention of origin anywhere on the documentation but Ketan said the chuck is Chinese.

First I took a steel dog end and turned it to about 1/2" to be concentric with the Myford spindle

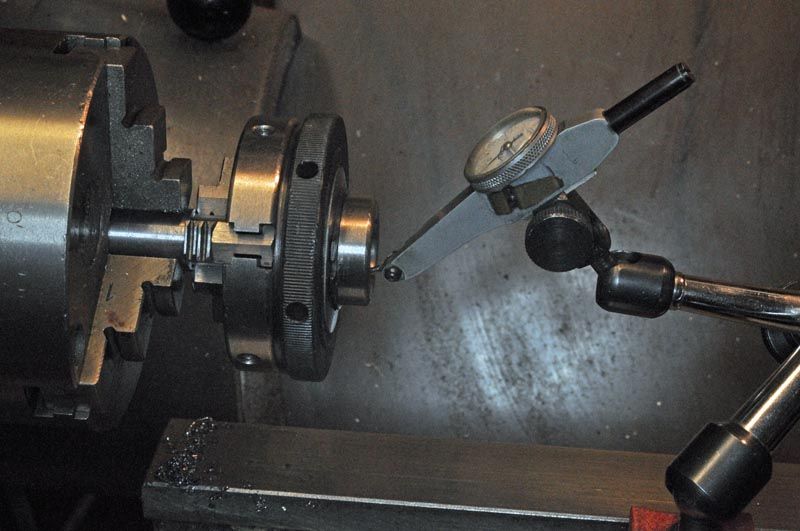

Then mounted the new chuck, in reverse, on the stub. I measured the run out here and the TIR was 3 thou.

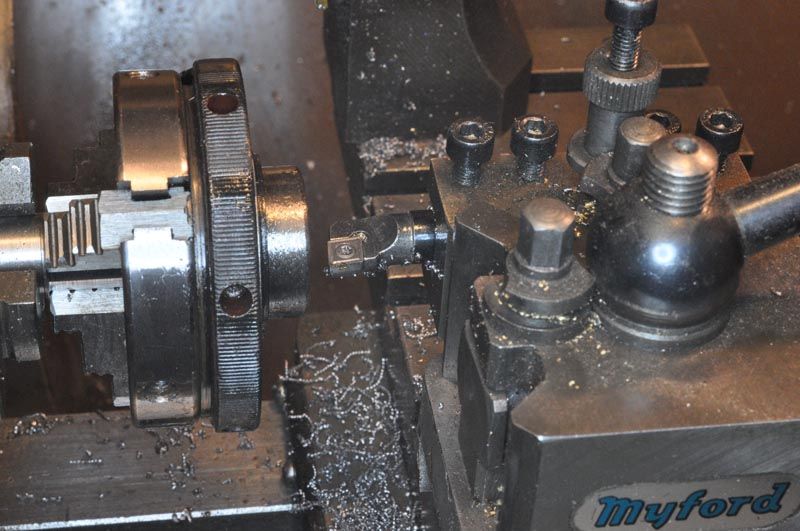

The body of the chuck was tough but machined OK so I turned away the 14mm thread and and opened the hole out to 3/4".

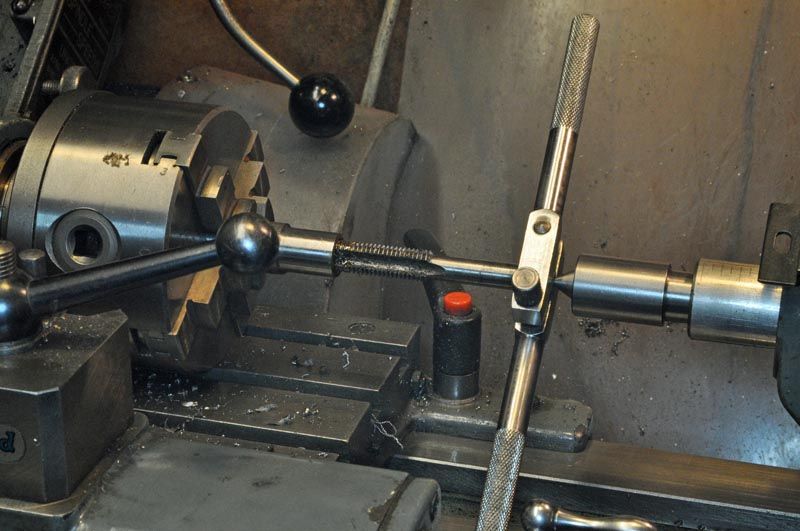

Another dog end was mounted in the Myford chuck and the OD turned to be a light press fit in the new chuck body. The Flexispeed spindle nose is 1/2" BSF (16 tpi) so I partially screw cut that, finished off the thread with a tap and then cut the 1/2" register before parting off.

The insert was annointed with Loctite retainer and pressed into the chuck with the bench vice.

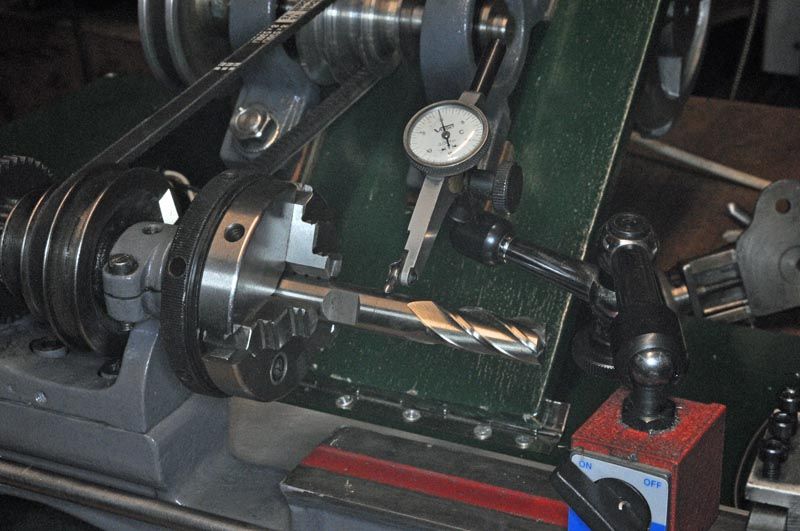

24 hours later I mounted the chuck on the lathe

Run out on this 1/2" endmill was a shade less then 1 thou TIR. Checking with 3/16" and 1" mill shanks, the TIR drifted out to 3 thou in both cases. I'm happy with this as being within specification – I don't expect a 3 jaw sc check to be collet accurate.

I hope this helps some others needing chucks for their Flexispeeds.

Rod

James Alford.