Jason has said it!

The feed per tooth will reduce, if the feed rate is reduced, for the same cutter rotation speed.

Feed per tooth is determined by the type of cutter in use, and the material that it is cutting. This, combined with the speed of rotation, will give a MAXIMUM feed rate, i.e. ,the speed at which the cutter traverses the workpiece.

With a feed per tooth of 0.002", a single tooth flycutter operating at 100 rpm will travel at 0.2 inches per minute relative to the work.

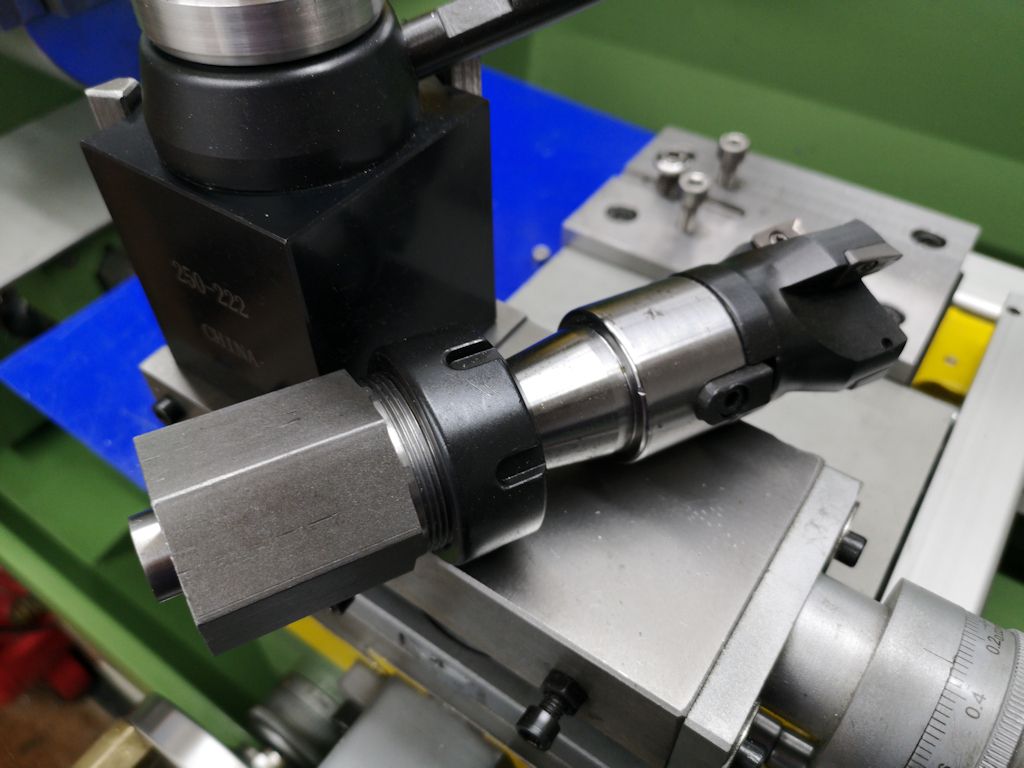

An inserted tooth cutter with 20 teeth will travel at 4 inches per minute, all other things being equal. They won't be, in that a 20 tooth cutter will, be larger, and so likely to rotate at lower rpm, for the same cutting speed. So the actual rate of travel is likely to be less than 4" / min..

But it will remove metal a lot faster than the flycutter, and need more power to do it.

If the 6 inch vertical slide is made of parts with the same section as the 4 inch, it is likely be more flexible.

Hopefully, being taller, it will be made of thicker section components. IF in proportion, (say 0.1 is increased to 0.15 ) the individual parts will be 3.375 times as stiff, but being half as large again, the stiffness, overall is only likely to be 2.25 times that of the 4 inch one. Having said that, a doubling of stiffness is to be most beneficial!

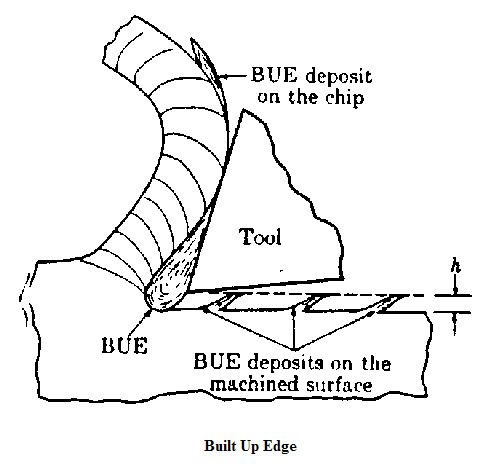

Blunt cutters have nothing to recommend them, in my view. A sharp cutter, properly aligned, requires less power, and cuts more cleanly, with less tearing.

Howard

.

Anonymous.