Posted by Simon Williams 3 on 22/04/2019 17:05:10:

I don't understand the force indicated on what I take to be the plastic wrapping for the strut in Nm? Am I missing something?

Rgds Simon

Offered as a suggestion!

I think the force needed to operate the strut is given as a torque measurement because they're most commonly sold to support car tail-gates or boot lids.

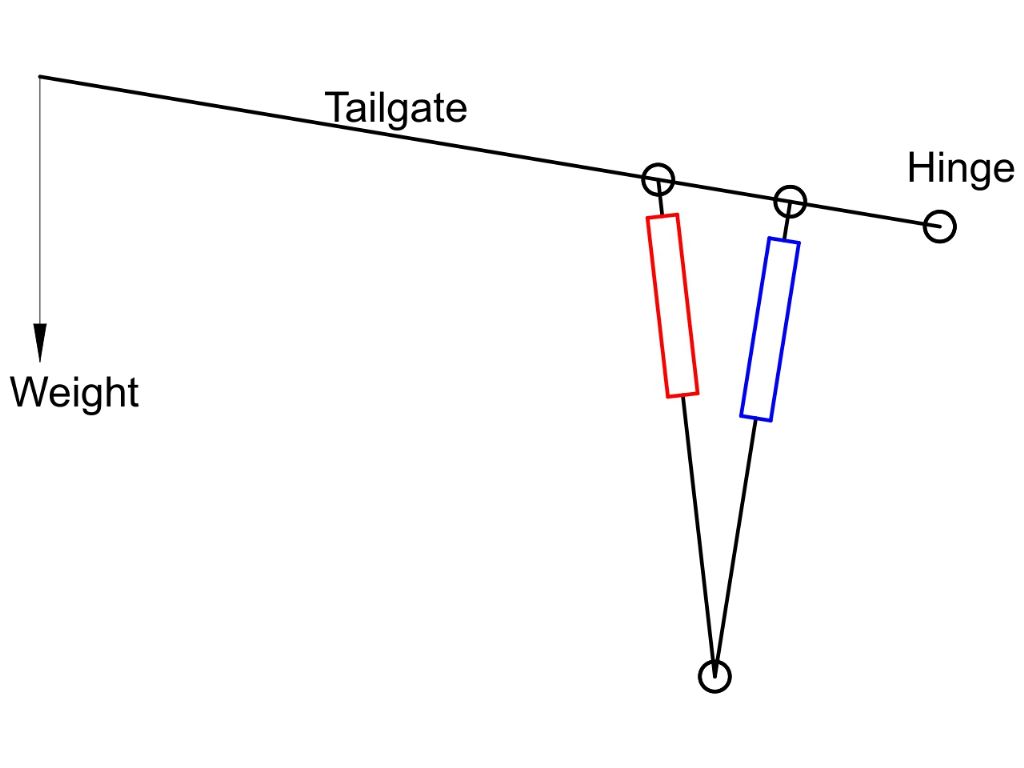

The diagram shows a tail-gate applying a weight to a gas strut. More force would be applied to a strut mounted in the blue position than one mounted in the red position. So choosing the right strut depends on the weight of the tailgate and the struts position along its length. As the tail-gate is hinged, a turning force is applied to the strut and, like a torque wrench, it's expressed in Newton metres.

I won't attempt the maths needed to translate 850Nm torque into the equivalent weight of an up down milling head. My maths is terrible at the best of times and I've got hay fever. 85 Newtons is roughly 85kgf, or 190lbf.

Dave

Nick Hulme.