Neil;

I see no other way of fixing the replacement dovetails in place, short of making a whole new head.

Jason;

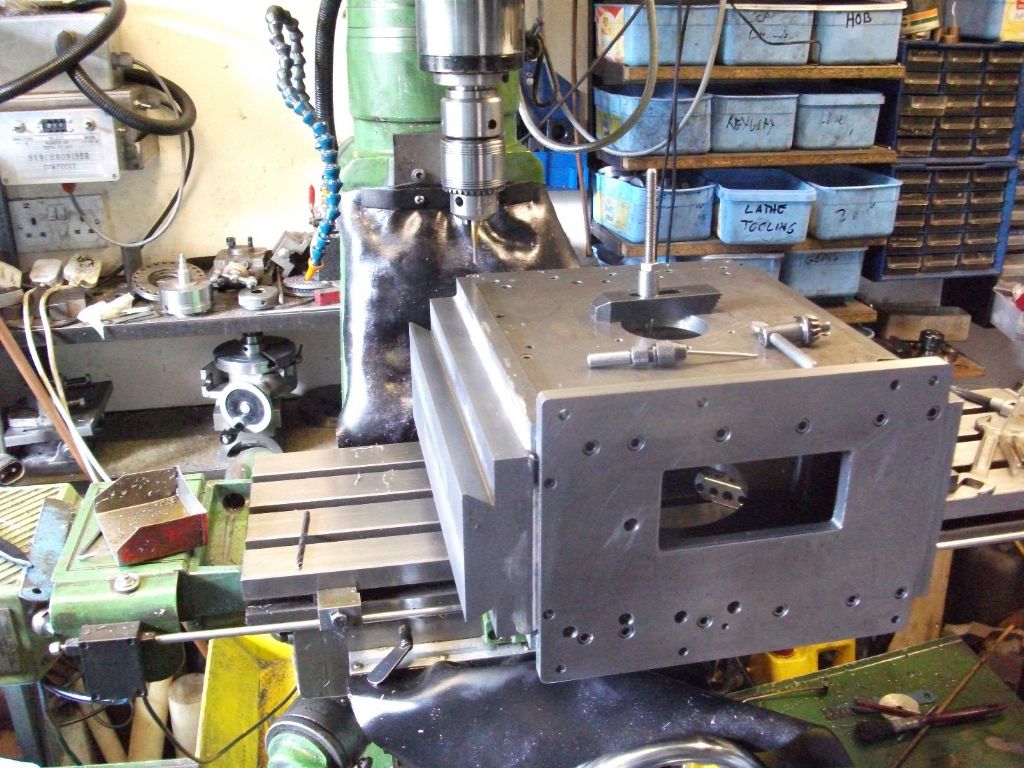

I thought of tangling the part and using an end mill – problem is getting the new part to align properly with the remaining old part. Dovetailing in situ would allow correction of any linear misalignment of the new block.

John;

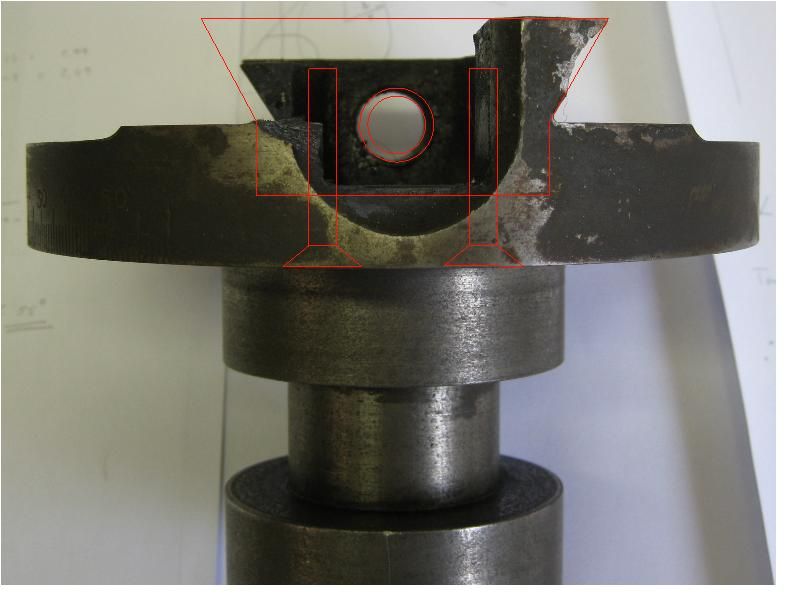

I am intrigued by the dovetail cutter you made. Can you explain a bit more for me please? How did you do the cone before slotting in the carbide rods? Was it just a , say, 45mm diameter 55deg cone , holes drilled at 55deg very close to the periphery, almost breaking out but not quite, and then machine the cone down to expose the holes, ie, remove half a hole, slot in the rods and silver solder and then grind the cutting edge open? I think you did differently, since in the first photo I see the soldered length of the rods are already almost fully exposed, not siting in 'half-holes'.

I have a quantity of 4mm square HSS , about 150mm long each. I could cut those and mill slots in the cones sides to fit, but would silver soldering the HSS not ruin the temper/hardness? Re-hardening/tempering in-situ would not be easy.

I like the idea and am interested to try something along these lines. I was looking at making a cone, milling flat faces to take the rhombus shaped carbide inserts, the smaller included angle is about 52 deg. I was thinking of silver soldering the inserts on to give more rigidity to the backing. The inserts are small, about 12mm long x 7mm wide, so I would have to work down the dovetail sides – could not cut the hole dovetail length. But your implementation is very attractive. Please tell me more!

Regards

Joe

Malcolm Foster 1.