My word – Aladdin's Cave!

First off – the orange assembly – I suggest is a 2-axis direct-indexing table for use on a drilling-machine. I am not sure it would be sturdy enough for heavy milling. The handle simply lock the table but the associated metalwork looks complicated enough for it to have operated an indexing-feed.

The four larger holes in the face-plate appear owner-drilled for a specific work-piece or jig, suggesting a career in a batch-production or single-product machine-shop. The smaller holes seem more random but don't look like carelessness so might have had a similar purpose.

The little oops! on that innermost ring, and the broken T-slot edge, make me think them isolated accidents in a machine-shop that generally used its equipment properly and carefully. (A lot more carefully than I have seen…) That colour is unusual for machine-shop equipment, so possibly owner-applied, maybe as a form of asset code.

Not part of a wood-working machine, perhaps?

'

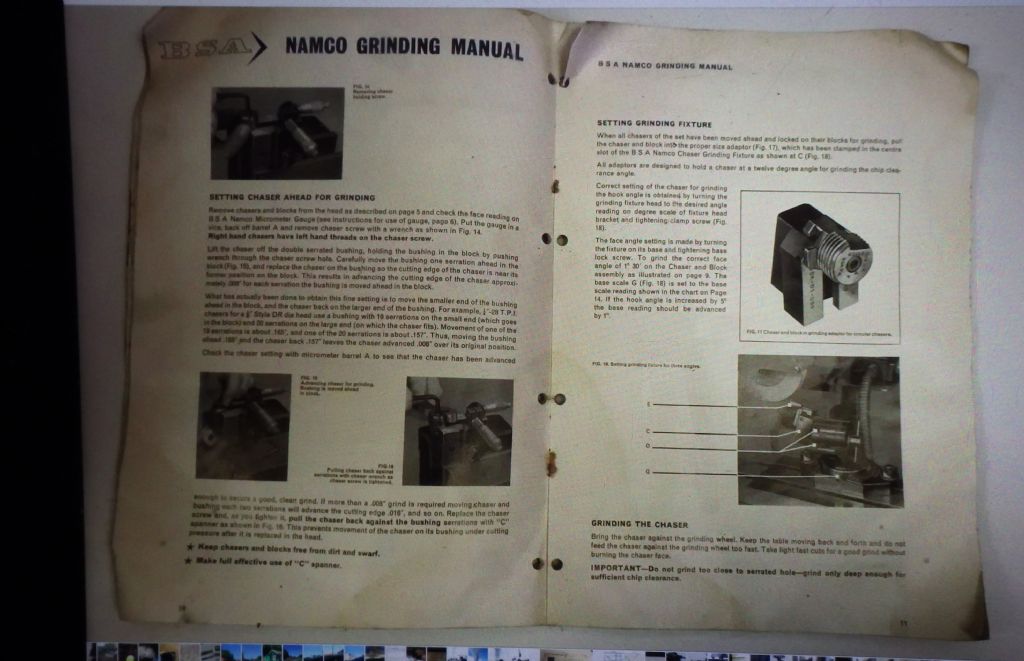

I'd guess the BSA-made item is part of a tool-&-cutter grinder – I assume the box next to it holds something related and is not just co-incidence. BSA was a major British manufacturer of motorcycles and tools, but started in armaments – British Small Arms – hence the rifles trade-mark on the box.

'

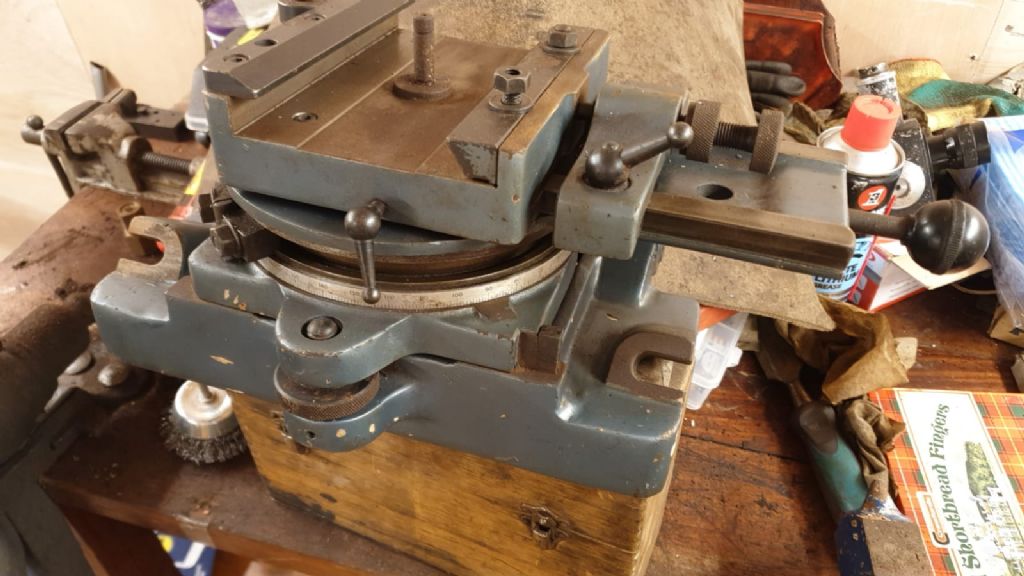

I'd say the assembly in the last two photos is from some sort of jig-borer.

The entire upper works seems adjustable through a small angle for level. Is it an optical illusion or are the mounting-lugs actually at an angle from the vertical?

The rotary function has what look like angle-stops. The left-right slide has a relatively massive, but micrometer-adjustment, travel-stop. I am puzzled why its slide-ways are offset from the rest of the device.

The top-slide's hefty dove-tails suggests it took the brunt of the moving for whatever the thing did, but I can't think what the projecting stud was for. It seems an odd place for it.

Whatever it is, exudes very high precision work!

Nicholas Farr.

Nicholas Farr.