Good pieces of work, Anthony & Phil.

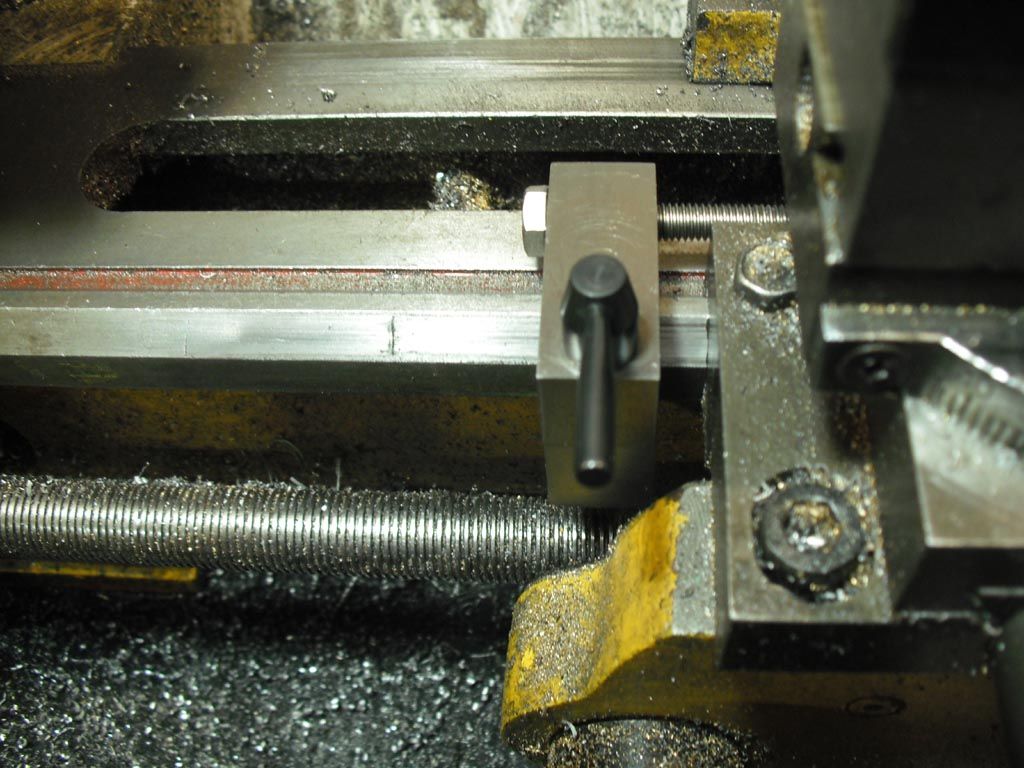

I like the idea of the bolt on the saddle-stop, for swarf clearance.

@@@

Me? Today?

Tired to place an order with ARC Euro only they have closed for the duration. Let's hope they – and so many other businesses including my local bakery – weather this storm.

After a late start resumed making my wagon boiler's lifting-cradle. It's a plywood fabrication that locates inside the firebox, with steel side angles drilled for Maillon Rapides (or equivalent small shackles) on four rope slings. A cord tied round the slings just below the top of the firebox keeps the boiler steady, and to my delight and surprise the load was in balance when suspended on the block-and-tackle.

The cradle also holds the boiler sufficiently stable to stand it on one of those "skateboards" on 4 castors – Aldis or Lidls, and I bought two, joking with the cashier about panic-buying trolleys.

The slings are lengths of ordinary 8mm dia. 3-strand hawser-paid polypropylene rope. (Polyprop is one of the stronger rope plastics, but has the lowest melting-point and has low UV resistance.)

I tried to splice the eye in the lower end as a splice is far more compact, better-looking and stronger than a knot, and better for the rope. Eventually I gave up in frustration, made a brew, and tied bowlines instead. The top end is clove-hitched (easily-adjustable) to a triangle folded and welded from 12mm stainless-steel rod. I had picked that up somewhere as something useful somehow.

(I learnt those two knots while in the Scouts – bowlines were also once a near-universal knot used in caving – and they are among the barely dozen knots I have ever had to use for all manner of things.)

Splicing is of the hermetic arts. The basic eye-splice in 3-strand rope starts with a move that very easily makes the rest all wrong. Intuitively, it weaves three strands through two gaps with no two ever sharing one gap or leaping over two adjoining strands. No wonder Escher stuck to drawing staircases and mill-streams.

Ironically my stock length of rope came with a professionally made, thimbled and seized, eye-splice at one end.

Nigel Graham 2.