Today – three us on an expedition to collect a Warco milling-machine one of the others had bought from t'other's brother.

As we were securing it to the trailer, we spotted a distinctive, large fork-tailed hawk fly over the neighbouring houses. The sister-in-law told us it was a Red Kite, recently introduced (or re-introduced?) to the UK and now common in some areas.

Yesterday – some Urban Engineering….

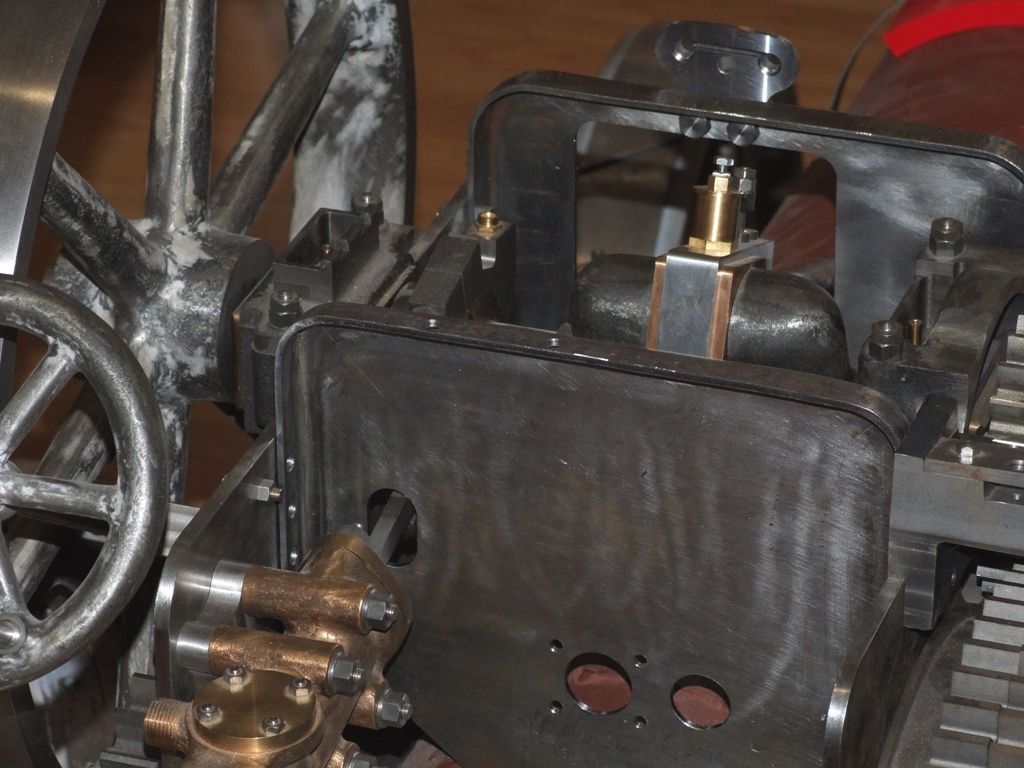

The front roof down-spout of my Edwardian end-of-terrace discharges into a concrete invert to the gate-post, thence a rectangular-section, concrete duct sunk into the pavement, to the road gutter.

Or thence, if not choked solidly with earth. I resolved to un-choke it.

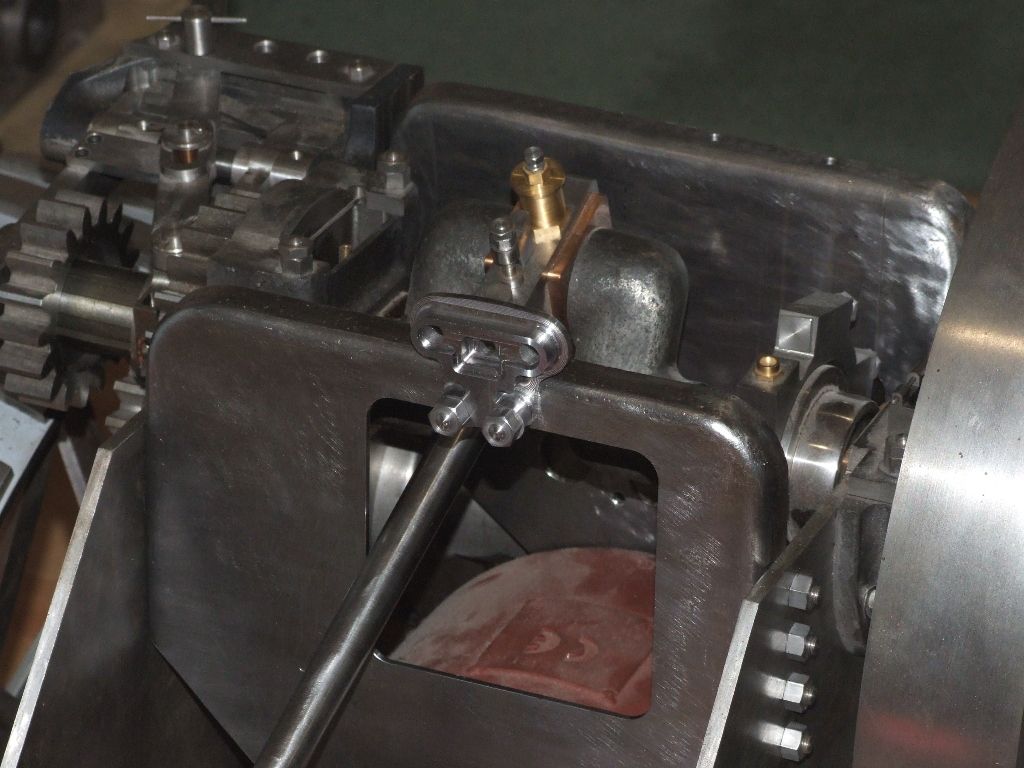

The three cast-iron cover sections were each held with a central M8 hex-headed mild-steel set-screw that, predictably, had rusted into whatever it engaged beneath. Despite optimistic Plus-Gassing, the first screw simply sheared, but that allowed me to lift the lid to reveal a simple but ingenious arrangement.

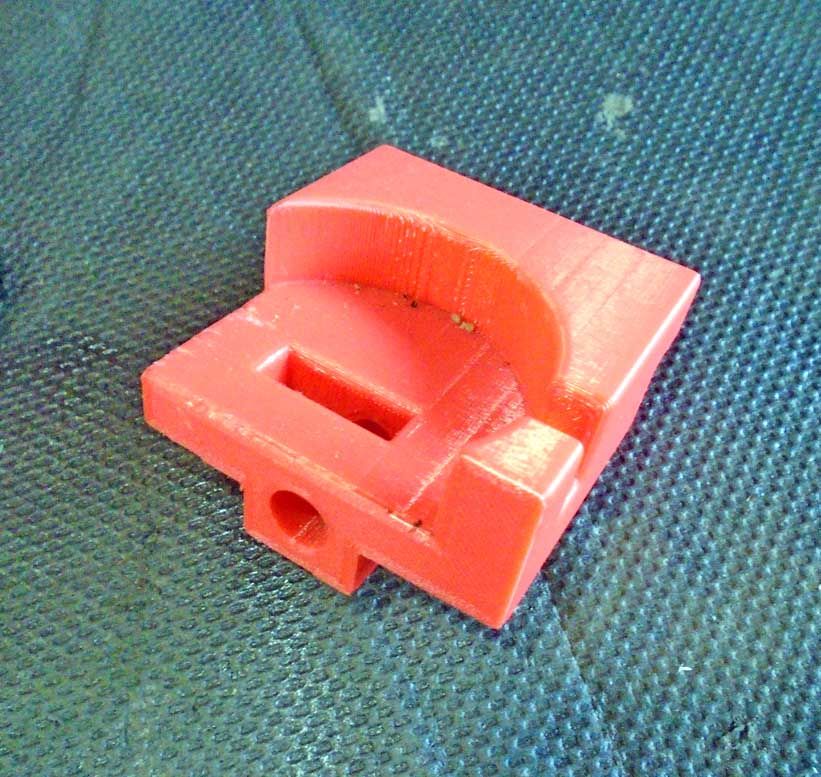

The "nut" was a tapping through a pressed-steel channel cross-bar resting in two plastic pockets in the duct walls. One end of the pocket is square, the other arcuate, further, the pockets are in diagonal opposition; so the engaged screws turns the cross-bar turns clockwise until it stops at the square ends, then allowing the screw to be tightened.

Needless to say, the remaining two screws and cross-bars were corroded palimpsests, but I salvaged enough to measure.

A little band-sawing, bench-drilling and hand-tapping turned a bit of hot-rolled m.s. bar (some scrap bar-rail) into three new cross-bars.

Ferreting in the unsorted come-in-handy deposits found three M8 hex-headed screws, and in stainless-steel.

With the duct all nice and clean, it was easy to complete the work with lashings of anti-seize grease on the new cross-bars and screws.

The finishing-touch was a simple strainer on the inlet – cut from a piece of Packaging, Plastic Plate, Perforated, Pliers for the Presentation of, from Aldi or Lidl

Can I claim a Council Tax rebate – or will They query my lack of hard-hat, shiny jacket and project-managerial meetings?

Nigel Graham 2.