Posted by Martin King 2 on 26/02/2019 17:08:11:

Hi All,

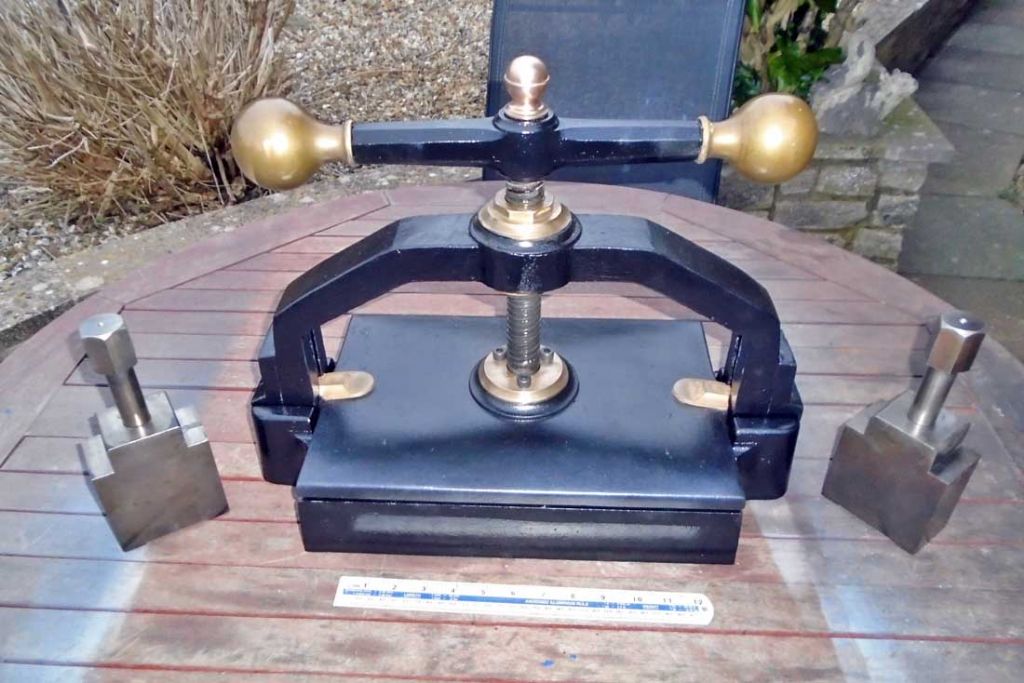

Just made these two large bolts for an antique book press that was fiitted with riser blocks so the bolts were too long.

This was my first attempt at a serious thread 7/8" by 9tpi, 36mm AF and it did not go without incident!

I decided to cut both threads using either end of a single bar; the first one went absolutely fine and I was very pleased at how easy it was!

Turned the bar around and did the scratch pass into the dykem and checked the pitch just to be sure. Started taking 5 thou cuts in back gear.

Halfway through the next cut or so I got distracted and turning round I must have caught the cross slide and accidentally wound on 15 more thou! Result was a big bang and my Tufnol tumbler gear disintegrated! Wrecked the HSS cutting tool also.

Got a new one a couple of days later and installed it. Everything else had been left exactly as it was so I carefully did a blank no cut run to see that the alignment was all OK.

At this point my brain deserted me as I reset the next cut at 2 thou to check alignment again TOTALLY FORGETTING that the disaster happened halfway along the work and I should have started the check cut at the high point to the left of the previous cut!

YUP, another bang and wrecked tool and tumbler gear!

Walked away in disgust for a day or two when someone on here very generously lent me a gear so I could finish the job while waitng for a new one. ( Thanks Brian! its on its way back to you!)

Some serious lessons learned and finally got it done.

I am now the owner of what must be the two most expensive bolts ever!

Cheers, Martin

Martin, in spite of your frustrations, I'm very impressed with your restoration work. I hope the press goes to a deserving home.

For the record, these sorts of presses were originally marketed as copy presses for document duplication, not as bookbinding presses, though many ended up being used as binding presses, particularly the ones with generous (i.e. above about 3.5 inches) "daylight" between the platens.

In the pic is one of two dedicated bookbinding presses (known as nipping presses) I own. Its platens are 21" x 15" and daylight is 15". I've also got four copy presses dotted around the house.

Steviegtr.

Steviegtr.