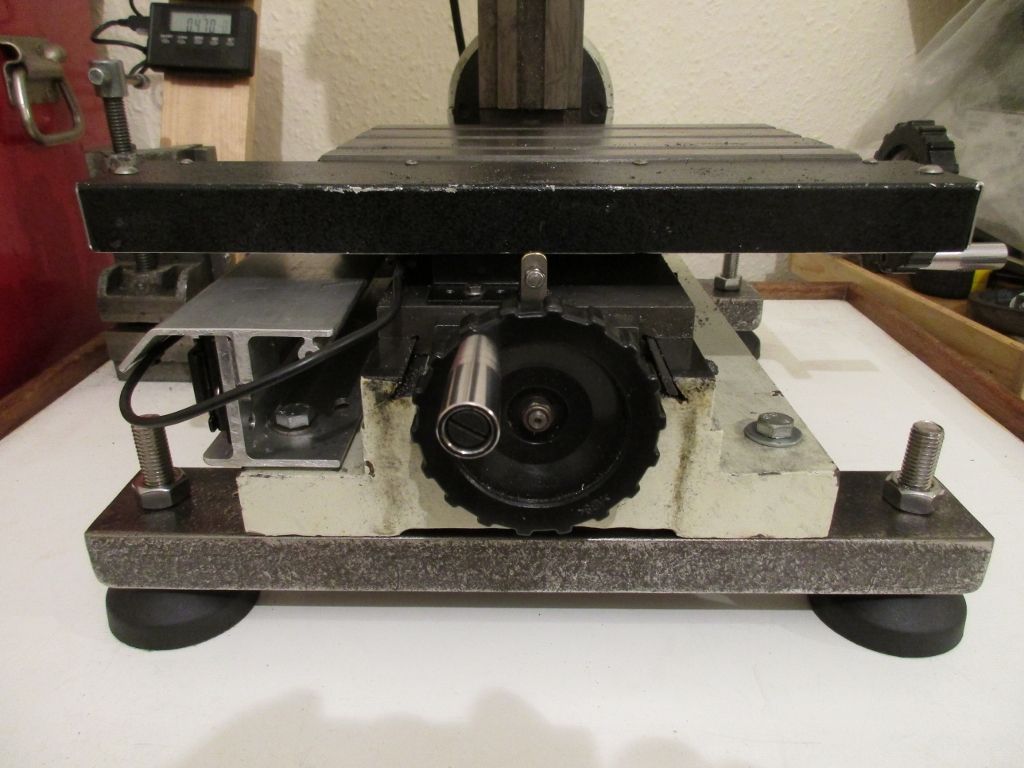

Hi, yesterday afternoon I drilled a couple of pieces of 50mm x 25mm steel channel and welded 12mm nuts on two of the holes on each one.

These are for my Cobra milling machine, which I've decided to unbolt from the stand so that it can be moved into different positions and which will allow it to be lifted off to make it easier to clean underneath and also give a little more clearance to operate the Y axis handle when used with machine mounts. Hopefully the machine mounts will suppress vibration, that I sometimes get, into the stand as well.

They have yet to be painted, but the above photo shows the front one in position. The machine mounts should also help prevent any twist in the base by not being bolted down. I believe the machine's weight will give enough friction on the machine mounts to stop it from moving around during use.

Regards Nick.

JasonB.

JasonB.