Iain –

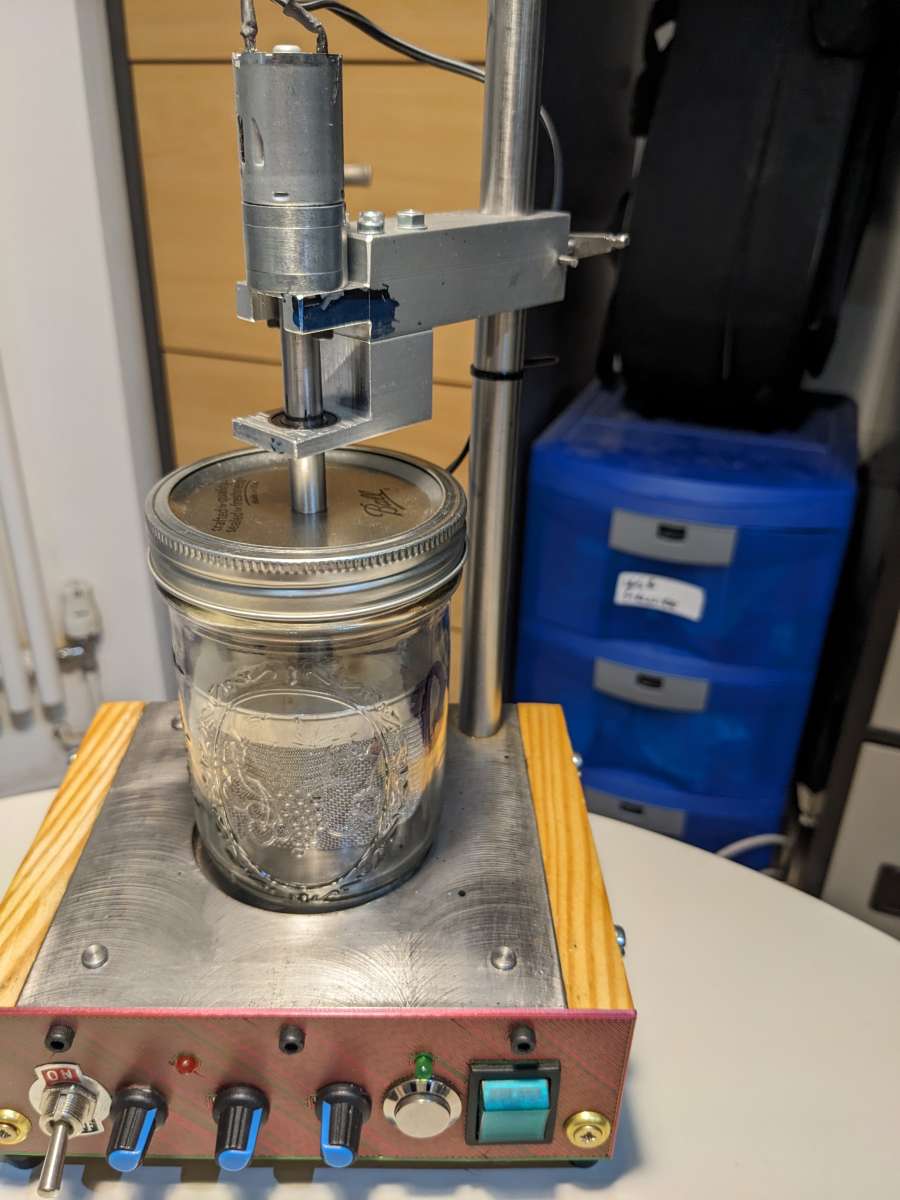

Fine piece of work! Is the jar a Kilner jar?

…

Duncan –

I doubt I could justify the cost of a plated and reground spindle though I don’t know what it would cost, nor who would carry out a small, non-trade task like that.

The lathe is basically in pretty good condition apart from the loose spindle, and that it having sentimental value is one but not the only reason for refurbishing it.

The lead-screw nut is probably quite worn as it is the only way to move the saddle for turning as well as screw-cutting, but would be moderately easy to replace. It is cast-iron, keyhole-shape in section (cylinder with a lug along its length), so could be sculpted from a rectangular block, or a steel strip secured to a cylinder by several small screws.

The flat bed seems to have been surfaced by fly-cutter, and though there is a patch where the arcs have worn off, much of it is still visible.

The tailstock screw is rattly but the barrel is still a reasonable fit in the casting. Its graduations are worn but recoverable – e.g. use a larger lathe to hold it and hand-swing the barrel against a thread-cutting tool as a graver.

My thought for holding the two separate headstock castings is to make a short version of the bed to which they can be clamped, and the assembly either fitted vertically to an angle-plate on the mill for the boring-head, or to a larger lathe for boring-bar access. The tailstock is in sufficiently good condition to use as the centering jig.

The advantage there, especially if made for horizontal boring, is creating a jig that could be useful for making further accessories such as steadies for the EW.

.

The lathe has its full suite of change-wheels, chucks, faceplate, boring-table and vertical slide so is a versatile little thing that would appreciate a little fettling! I may experiment with making a new spindle before going much further with the lathe itself. That’s a task for the Harrison lathe for which I have a collet-chuck, and which gives extremely fine self-acting feed rates.

Finishing the register, nose-thread and taper-reaming of course is done on its own lathe.

It’s clear from this site that there are quite a number of we EW Lathe owners about, some Doing Things that enhance their lathes though I prefer to make clamp-on accessories fitting what exists, to modifying the machine itself.

‘

Sentimental?

And restoring long-case clocks, Holtzappfel lathes, vintage cars and steam-locomotives isn’t? 🙂

Dalboy.