Posted by STK2008 on 02/04/2018 09:29:40:

T

…

…

Well I think you lot have made my mind up I shall be ordering these two machines up ASAP  .

.

To next issue then LOL my machine shop is small I measured up and the machines will JUST about fit.

Only thing now is the milling machine with the head all the way up it says it measures about 1050mm and on the stand it measures a total of 1800mm or so. the roof in my garage is only 2000mm high.

When lifting the milling machine does the head HAVE to be at the very top to lift it or can I lower it as close to the bed as possible then slap a sling around it just behind the chuck?

this will allow me a lot more clearance for the crane and the roof of my garage..

…

Manoeuvring a heavy lathe and mill in a tight space with a crane can be tricky. Don't rush it, rough out a plan of campaign and have a dress rehearsal. Depending on the layout of your workshop it may pay to put the mill in before the lathe or vice versa. I drew a scale diagram of my garage on some squared graph paper and used cut scale rectangles representing workbench, mill and lathe to check fit and operating convenience in various combinations. Doors and windows have a strong influence on layout: how I wish I'd bought a house with a double garage!

Despite careful planning l came unstuck positioning my lathe with it's back to the wall because there wasn't quite enough width in my garage to turn the crane. Actually that did me a favour, because I realised that plonking the lathe down sideways gave me much better access to the headstock for changing belts and gears and passing long work through the spindle. I can also get to the back of the lathe easily which has been handy on the few occasions I've wanted to look at the electrics. My original assumption that saving floor space by putting the lathe hard against the wall lathe was misplaced!

Milling machines are less fussy but don't forget to allow enough space on either side of the mill for its table to fully traverse right / left.

The milling head should be as low as possible when you lift it, not at the top. One issue moving machine tools is that they are liable to be top-heavy and unbalanced. Stopping them tilting and slipping in the harness is probably more trouble than simply lifting the machine with a crane. Much easier if there are two of you – the assistant doesn't have to be anyone special. Position the straps carefully to get good balance and lift the tool just off the floor to check it's secure.

If you have any trouble come back and ask again. Many chaps on the forum much more experienced with moving heavy kit than me. They can advise on other ways and means should the crane approach become problematic. (For instance, due to limited head-space.)

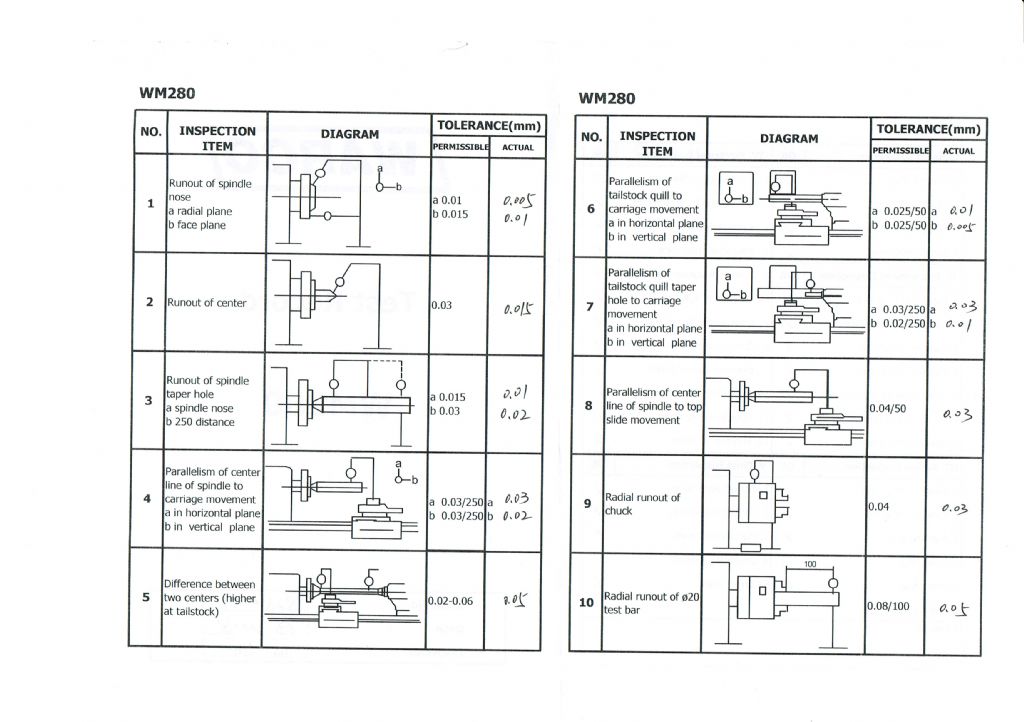

I have a WM280 and a WM18 and they do everything I've asked of them. Fit for my purposes and value for money. Be prepared to do some expectation management though! They are not tool-room accuracy, nor are they made for production work. Remember that a professional machine will cost you between 6 to 20 times as much.

There will be cosmetic issues and don't be too surprised if some aspects of assembly need minor TLC. Beware lots of elderly internet advice that Chinese machines all have to be completely stripped down, fettled, and rebuilt before they're any use. Unlikely! True that the occasional dud slips through the net; if you find anything unacceptable talk to Warco.

Good luck – I hope you have as much fun with your purchases as I am!

Dave

Edited By SillyOldDuffer on 02/04/2018 11:33:21

Edited By SillyOldDuffer on 02/04/2018 11:34:16

David Standing 1.