You know those jobs you wish you had never started!!

So when pushing the mill, the gears can make a tremendous knocking sound.

Being the inquisitive type I really wanted to find out what's going on. With a view to identifying any potential issue early and thus prevent any further, potentially irrecoverable, damage.

On my Harrison M300 lathe, viewing the gearbox is a simple matter of loosening a few cap-head screws and lifting off the top plate.

The Mill looked a little more involved, but not a lot more (spoiler: I was wrong)!

Remove face plate and dials:

Remove the motor:

Remove the 6 cap-heads and simply lift the top plate.

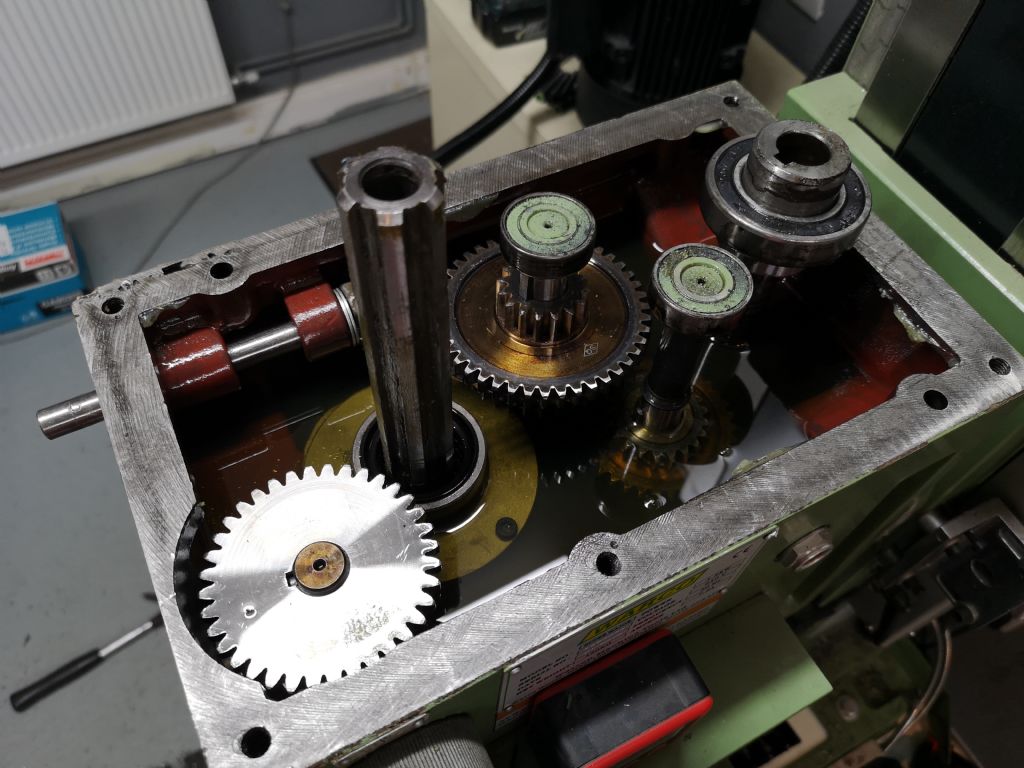

Ah, balls! Looks like the gears get lifted out with the top plate.

Have a quick peek inside, then put the plate back on.

After much; pushing, pulling, bashing (rubber mallet) and screwing (using them as a press, it went back on.

Put everything back together and forget the the whole thing.

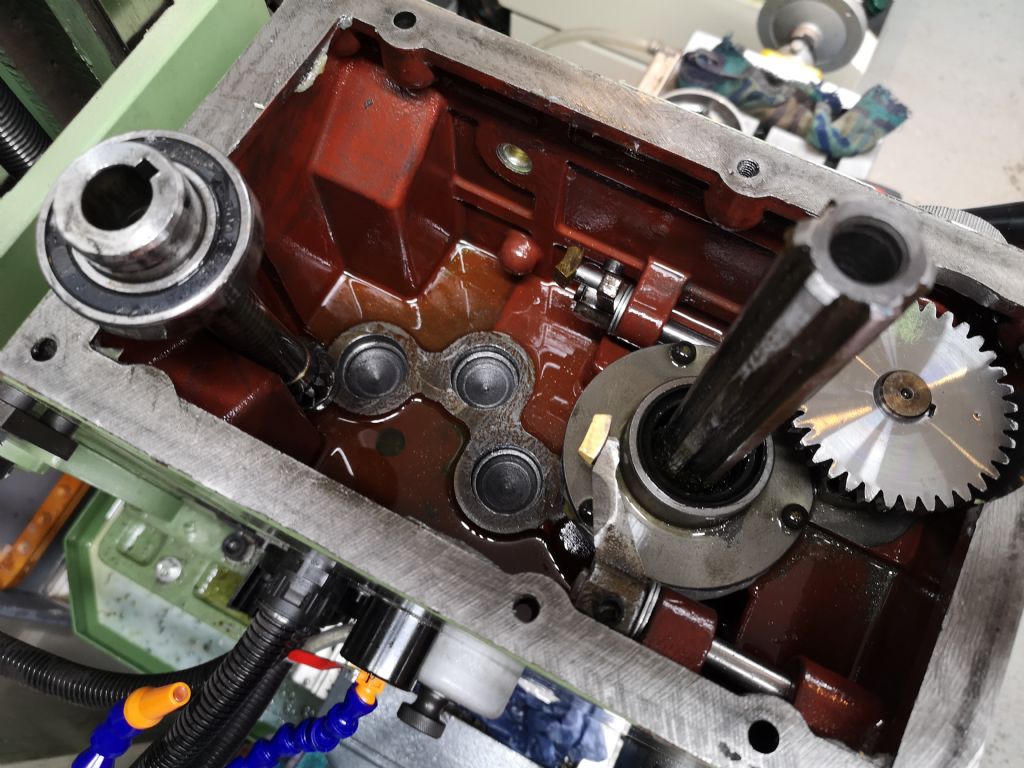

Ah balls! The 1, 2, 3 gear selector has disengaged !!!

Re-strip – this time we need to go big. In for a penny …

Taking another look at the exploded view parts list to locate all of the curclips and bearings.

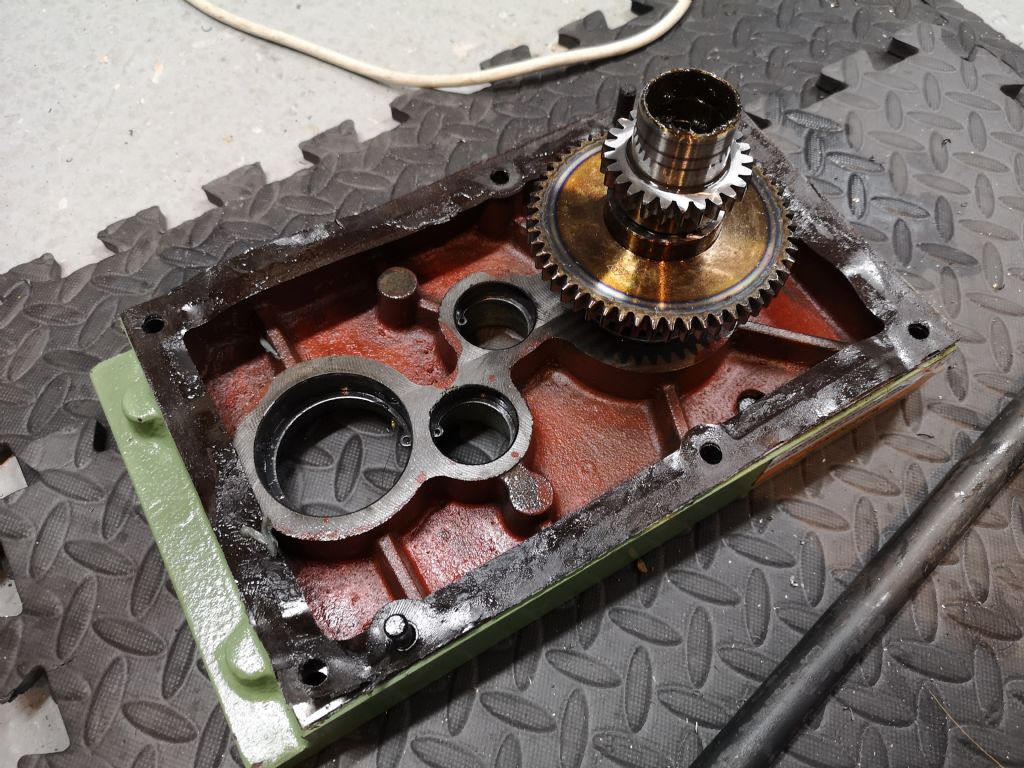

Now we play a little game of 'jimmy up the plate and bash down the gear shafts' using pin followers (so as to avoid lifting all the gears out before I've had a good look at them).

Success:

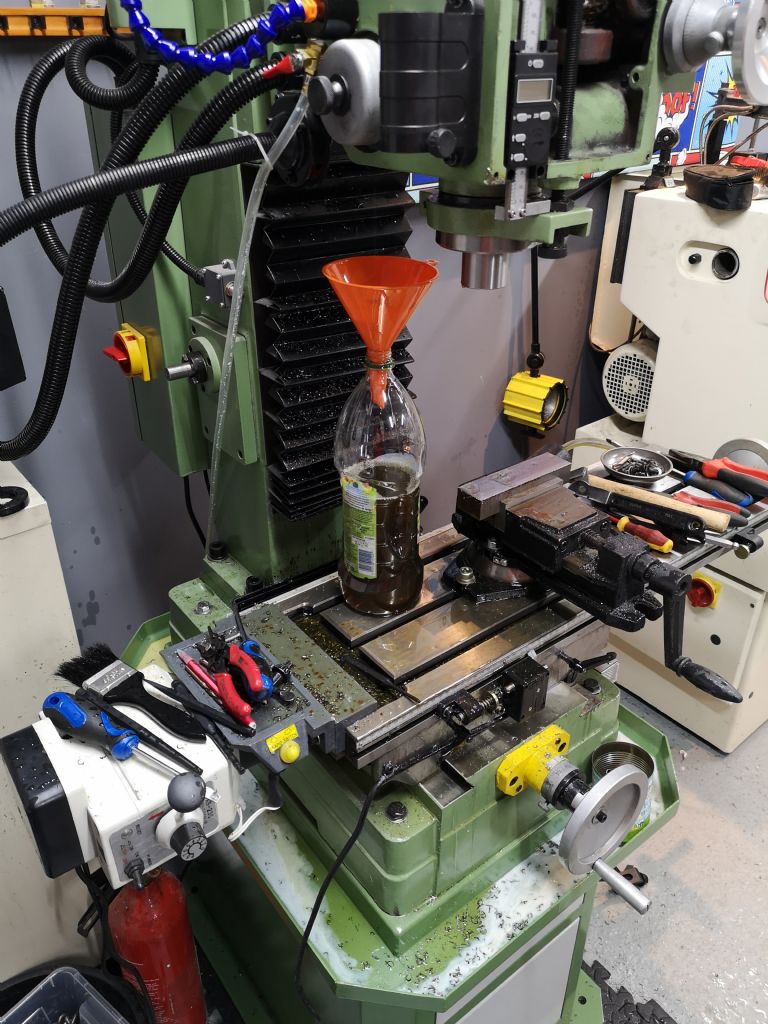

Now time to drop the oil.

Ah balls! Dropped the plug and overwhelmed the funnel.

Oil everywhere. All over the floor and contaminated the cutting fluid system:

Gears out:

Nothing appears out of sorts. No worn teeth. Everything looks tight and in good order.

Time to put it all back together again.

Also think I found the source of the clattering. There's a plate at the back of the mill head which protects the screw. A little grub screw keeps it in place which was pretty loose:

Once we're all back together, I'll give it a test by removing it during a heavy cut.

Fingers crossed!

larry phelan 1.