I spent my time today ensuring that my measuring systems were as good as I can get them before attempting to carry out any of the Edwin White process.

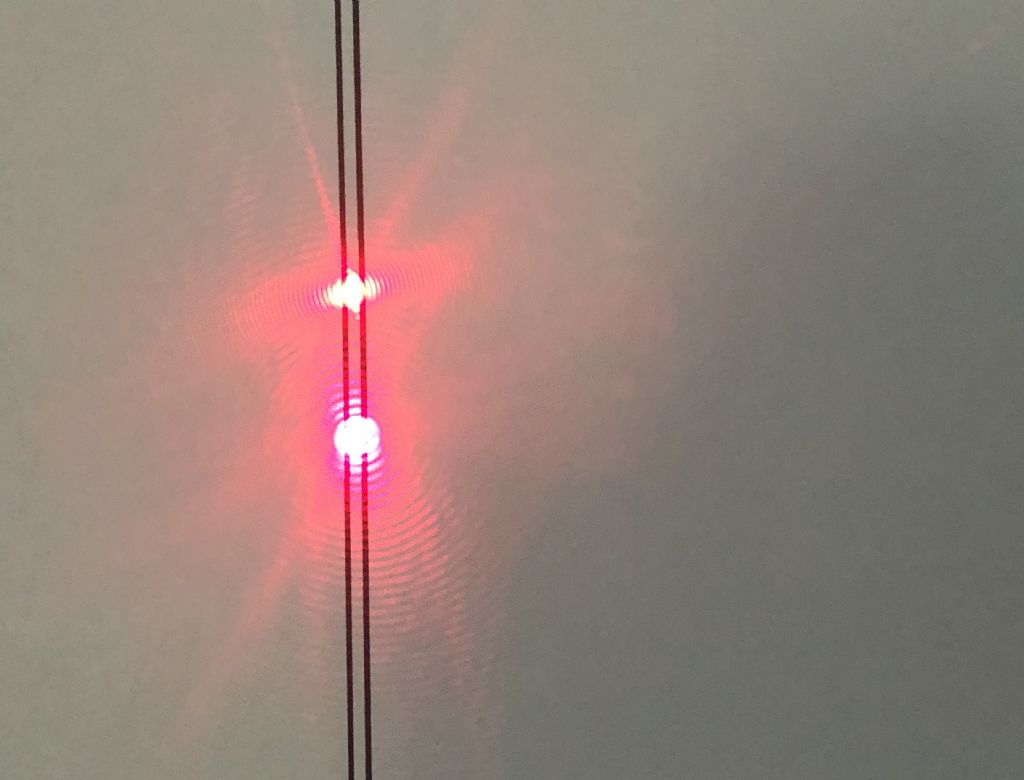

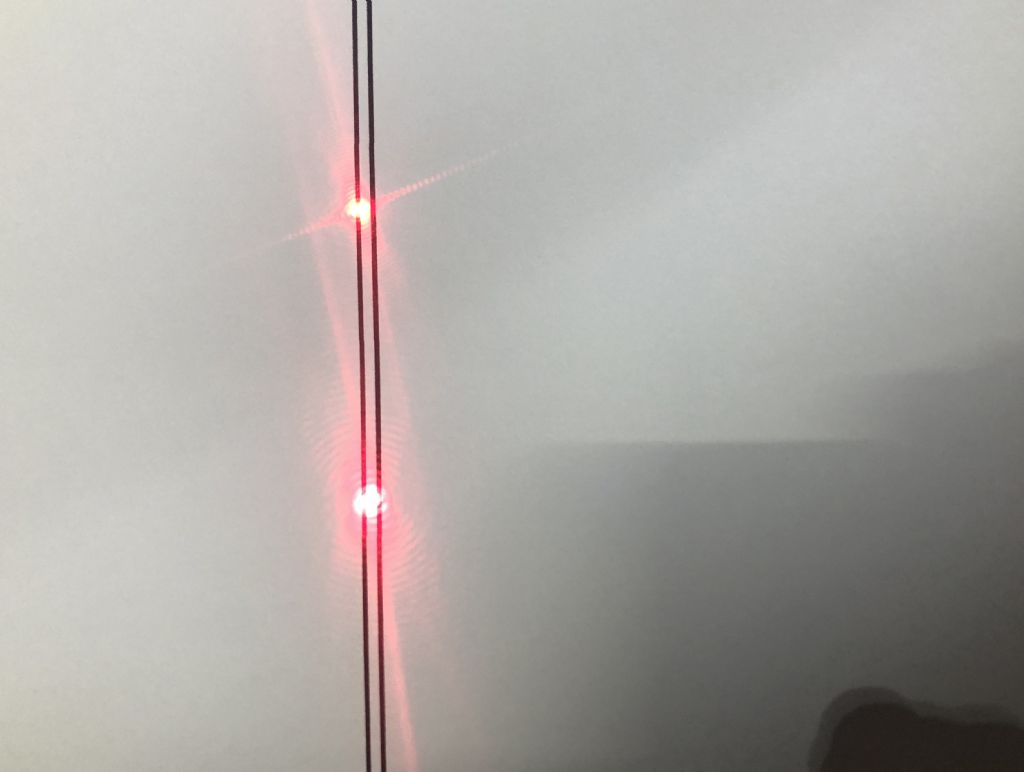

The ( expensive ) surveyors laser measuring device only gave a marginally better 'dot'.( The top one in this picture )

When used in comparison with the dial gauge on the quill I found that I could get results which allowed me to carry on.

I positioned the head .03mm off centre on the gauge and could see the core of both lasers displaced to the left line and return to centre when I 'zeroed' the head /guage position.

The object of the exercise is to measure the lowest position of the head and fix / screw the bottom of the rack there.

Then raise the head to its highest position, use the laser and gauge measurements to restore it to a correct alignment and fix the top of the rack there.

I have chosen to use two 8mm countersunk socket headed screws 40mm apart at each location to give the strength necessary.

Then I should be able to raise and lower the head and watch the laser dots track up the twin lines and watch any displacement on the dial gauge.

My mill is not horizontal on its stand so I will first measure the true extent of that error accurately ( thanks 'old mart'. ) and then angle the lines to the same degree so that the tracking is a true measurement of the head position. The guage reading should confirm the accuracy..?

Best Wishes

Terry T

Edited By Terry Turner 2 on 15/08/2021 20:12:08

Terry Turner 2.