The quill is out, the spindle is out and all the bearings removed.

The problem….and this is where some of you will say " I told you so"…..there was a bruise/ burr right at the top of the spindle splines which was sufficient to hold the pulley shaft so strongly that after the WD 40 loosened everything and I raised the quill using a wooden lever ( with a wooden block underneath for protection ) it pushed the pulley shaft and bearings out the top of the head….!!!

I was then able to remove it and all the bearings and spacer using a gear puller and the quill dropped out….!

I was then able to remove it and all the bearings and spacer using a gear puller and the quill dropped out….!

I had twice listened to your advice about the possibility of burrs on the splines and inspected those splines but missed what was in fact a flat round edge ' bruise'…? no sharp edges.

I had twice listened to your advice about the possibility of burrs on the splines and inspected those splines but missed what was in fact a flat round edge ' bruise'…? no sharp edges.

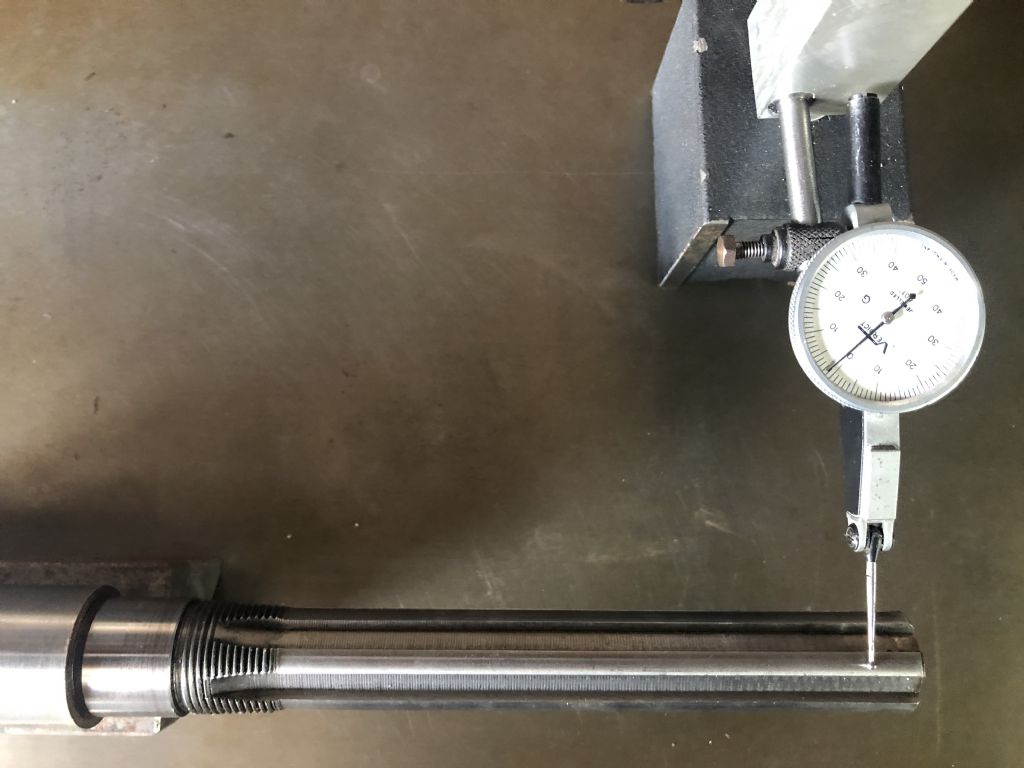

I did not believe that the 'bruise' was sufficient to jam things that hard so I put the spindle between two 'v ' blocks on my surface place and checked that it was true………it was…………the bruise/ burr was the actual / only culprit.

Both spindle bearings were in a shocking condition and I am ashamed that I continued to use the mill with that excessive run out and noise…

Both spindle bearings were in a shocking condition and I am ashamed that I continued to use the mill with that excessive run out and noise…

I have owned the mill from new and at some point I had damaged the top of the spindle..I was the author of my own misfortune.

Thanks again to everyone who responded and tried to help, Old Mart, DiogenesII and John Baguley who continues to share valuable information.

At some point I will put the whole photography sequence together with a narrative as a U Tube video so it is available to everyone…

I am truly grateful for your information and interest.

Edited By Terry Turner 2 on 07/08/2021 20:17:35

Terry Turner 2.