Oh dear, the 290VF stand seems a bit disappointing. With the lathe weighing close to a quarter of a ton it does need a fairly solidly made stand.

Regarding the gap piece on the other new Chinese lathes, it is very odd to be discouraged from using a feature that they are built with and that is used as a selling point in the advertising.

The improved manuals on the Grizzly Machine Tools website have a few paragraphs on removing the gap piece, but they then strongly recommended that you do not attempt to replace it and that you accept the reduced travel of the carraige towards the chuck because of the open gap section that would leave the saddle partially unsupported, crazy!

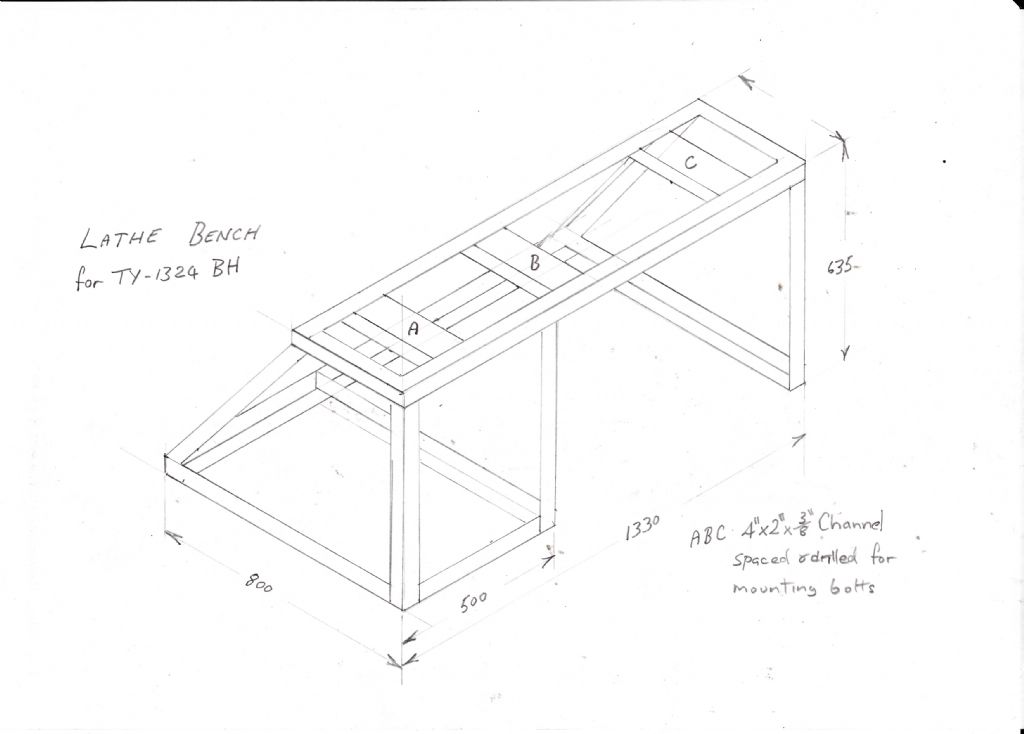

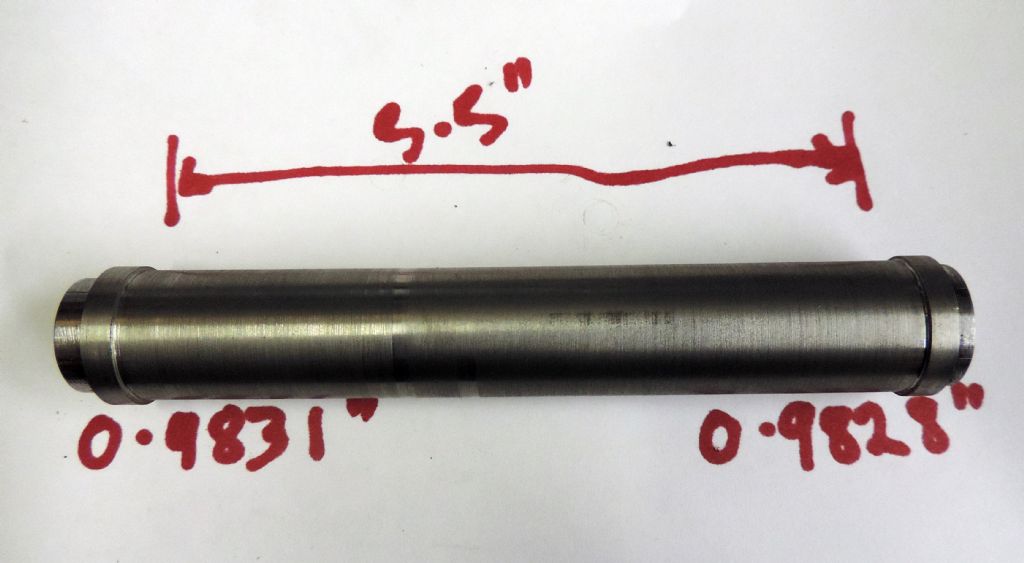

I have removed the gap piece on my Warco 1330 lathe, and despite the lathes other faults the gap section had been well prepared and fitted before machining and grinding in situ. I managed to refit it without too much fuss with careful tightening and a few deft strokes with a rubber mallet in the right places, so I don't know why they make a bit of a fuss about it. Maybe there have been some badly fitted examples from the factories that just cannot be refitted accurately enough.

Anyway Mark, have you run your new lathe yet or done a bit of turning with it?

Edited By Lathejack on 29/10/2014 00:02:31

Jesse Hancock 1.