I have two vices, both supplied by Warco:

I don't require them to 'last a lifetime'; I'm past my 'Before Date', and the hobby doesn't require me to thrash my tools. I'm sure they will last longer than I do!

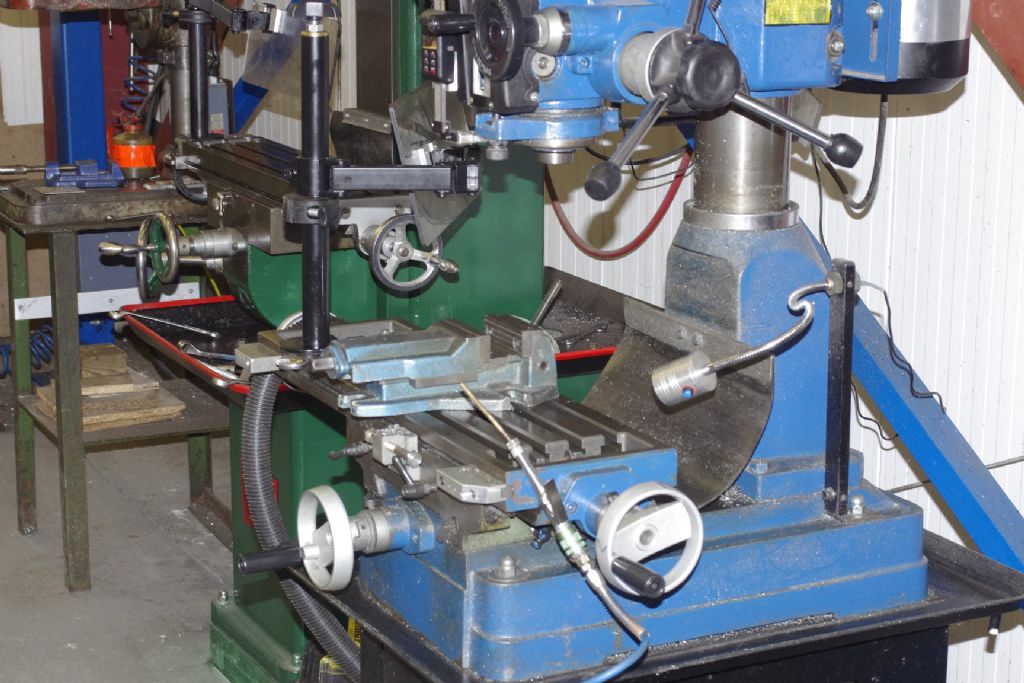

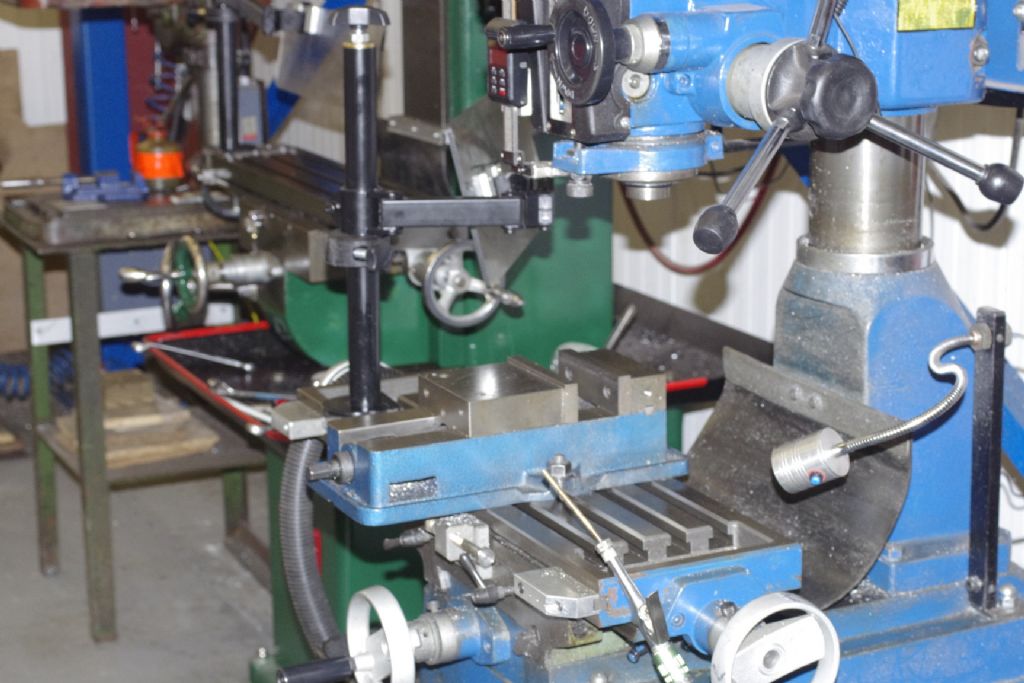

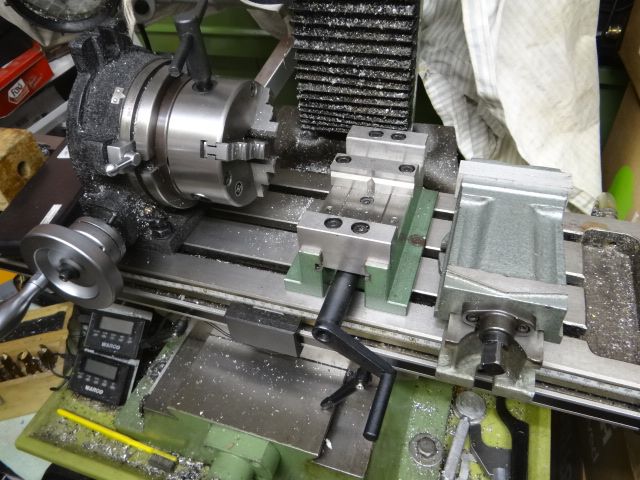

The vice on the right is an ordinary 100mm machine vice. That in the centre is a DH1, with 80mm jaws. Note both vices are removed from their turntable bases. Swivelling is rarely required, and the bases take up space and reduce rigidity. Turntables are almost unnecessary in my workshop, and many others agree. For the same reason I'm suspicious of Angle/Swivel vices – bendy!!!

Although the DH1 is only 80mm wide, it's holding capacity is greater than the 100mm vice. Its jaws can be unbolted and moved, providing much wider jaw opening. I mostly use it in the plain 80mm configuration, but every so often the wider grip is handy.

The 100mm vice has a couple of vices, ho ho! There's a slight tendency for the jaws to lift on tightening, which is so common that it's respectable in professional workshops to tap jaws and work down with a mallet to correct the problem. More serious is a design compromise. The rear jaw has a stress-relieving gutter, also serving to collet swarf. Unfortunately spacing parallels tend to fall into the gutter and making sure they haven't is a time-waster. Not a problem with thicker work, but I mill lots of stuff under 10mm thick, which is spaced carefully to height.

There's no doubt the DH1 is a better vice, but 80% of what I do can be done just as well with an ordinary one!

I think both vices are about the right size physically for a WM18. Wider jaws come with a disproportionate increase in size and weight. A 100mm vice weighs about 10kg, 125mm about 15kg, worse as they get bigger!

Dave

Edited By SillyOldDuffer on 12/08/2021 10:39:03

old mart.