Hi Matthew. I run the G1MRA Surrey Group and nearly all of my engines are meths fired, including several LBSC designs.

A few points.

1. Meths can indeed be of very variable quality, especially if somebody has left the cap off since it is hygroscopic.

Most of my group use B&Q bioethanol which is sold for flame effect fires. As well as being very good quality, it is typically cheaper than most DIY available meths. Sometimes it is hard to find in store – just ask. I know the name is odd. It's not as though the ethanol in meths isn't bio in origin…

If you really want a fierce fire, then some folk like isopropanol. This makes my engines a bit too frisky so personally I stick to bioethnol.

2. Your observed loss of pressure when the blower is opened is more likely to be lack of water in the boiler than a problem with the drafting arrangements. When there is only a small amount of water inside you could still get a high registered pressure on the guage, but as soon as you take some of the steam off there isn't enough thermal mass of boiling water to replace it. On the other hand, completely filling the boiler is bad too because that leaves little steam space and will lead to priming (water in the cylinders).

For a new engine that you haven't yet got experience of running, I suggest you take the safety valve out and invert the boiler with the blower open so that it completely drains. Then use a syringe and water to fill it up completely so that you can see the top of the water in the safety valve, keeping a note of the volume of water you've put in. Now drain again, close the blower and half-fill the boiler.

3. The recomendation to use glass fibre wicks is optimistic, in my experience. Glass softens at the sort of temperatures you'll get in a meths fire box, and the ends will fuse into blobs at which point the wicking action is inhibited. The best wick material available at the moment is probably ceramic fibre. This stuff is used for very high temperature insulation but is hard to get hold of. Some folk like cabon fibre. If you contact me privately me I will send you some of my ceramic fibre. Cotton wicks are pretty much useless in high performance engines as they char away so quickly. Traditionally asbestos was used: if you have an old engine with odd looking wicks in it then I would dispoase of them carefully.

4. For most 'internally fired' meths engines, including Smithies boilers, you initially need a small suction fan to draw the combusting gases through the tubes (or through the outer shell for a Smithies). Once the boiler gets a bit of pressure up you can crack open the blower (don't open it too wide and lose all your pressure!) and the entrained air will do the job instead. If you don't use a blower, the meths flames often will just billow about under the engine, which is a hazard to paint and fingers and theormdynamically hopeless too. Some engines will, on a calm day, eventually get up to pressure without a fan – I have an LBSC Chingford express which can get going without a fan as I discovered one day when I was testing a burner and hadn't fully extinguished it…

5. I've never encountered problems with soot in G1 meths engines. Now, coal fired G1 engines are another story and need very careful cleaning after a run. However, the smokebox doors of my meths engines are rarely opened, and I've never cleaned the tubes of a meths engine.

6. If this is a new build engine, pay very careful attention to sealing the smokebox to the boiler barrel, and also to sealing the entry of the exhaust and blower jets into the smokebox. The 'entrainment' effect depends on there being essentially only one way for air to get out of a smokebox, and that's up the chimney. Most of us use bathroom sealant to give airtight seals.

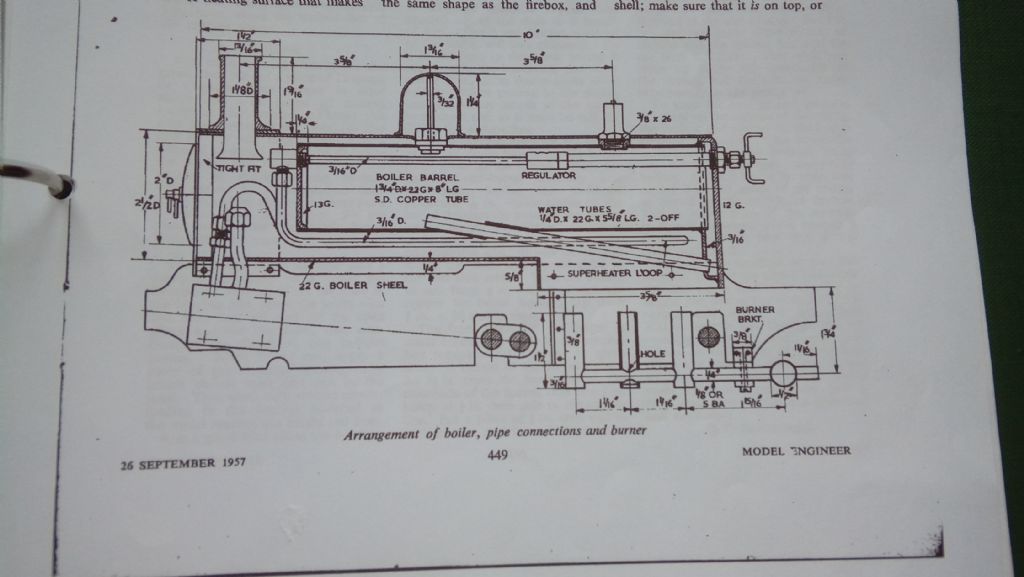

Of course, you also need to make sure that the firebox door has a good seal too – I see you diagram requires a 'tight fit'

7. Check the positioning of your exhaust and blower jets. The normal way to do this is to fill the boiler with water, attach a compressor (or even just a bike bump) in place of the safety valve and open the blower or turn the wheels. You should get small jets of water shooting out of the centre of the chimney orifice. If the jets are off centre or colliding with the chimney tube then you need to bend the exhaust/blower connections at the bottom so as to get good alignment.

Adrian

Edited By Adrian Johnstone on 07/08/2017 13:10:05

Edited By Adrian Johnstone on 07/08/2017 13:10:42

Edited By Adrian Johnstone on 07/08/2017 13:12:50

Mark Hogan.