Posted by fizzy on 09/11/2012 17:45:17:

also, when the motor gets very hot, which it does after prolonged use, the gear on it goes soggy ant the key tears through it. I have to praise machine mart for their parts service and cost of new gears, they are pennies each, usually in stock and posted straight out. I try to keep 3 of each in stock. Alas the electronics are utter rubbish and readily fail! Only on the machine mart model I am led to beleive?

I dont know what electronics are inside the machine mart model. ARC has sold plenty of the SX1/L over many years. Failure rate has been low. Based on conversations had with buyers who buy replacement gears from ARC, breakage has usually been when using a two tipped indexable carbide end mill – due to intermittent cut with incorrect feed/speed/depth, or when using a fly cutter at incorrect feed/speed/depth, depending on the material being milled.

Again, this is a light duty machine, designed for intermittent and not prolonged continuous industrial type use. It is a hobby machine, built for the hobby market at a price dictated by mass affordability, rather then rugged precision continuous/industrial use, which in turn would be more costly which in turn would suit a more limited affordability market.

First you suggest that the gears are rubbish and then you suggest that the electronics are rubbish. Perhaps you need to pay the price and consider a bigger machine more suited to your needs, rather then slagging off a machine which is not designed for the purpose of YOUR intended use!  .

.

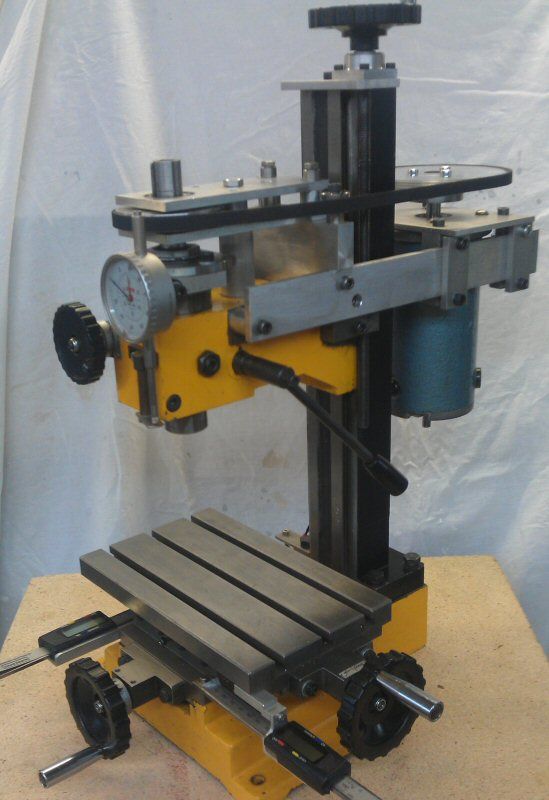

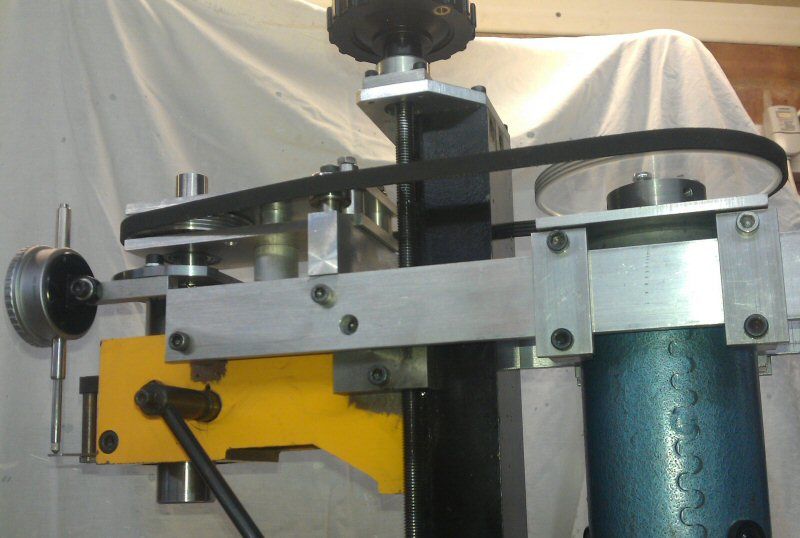

At the end of the day, you definitely get what you pay for. ARC has been extremely happy with the sales of SX1/L over the many years we have been selling them. What customers wish to do with them in terms of adding belt drive is entirely up to them. At the end of the day it starts off as an economical light duty machine. This is a hobby, and the conversions I have come across are good, bad and ugly.

Ketan at ARC.

John Stevenson 1.

.

.