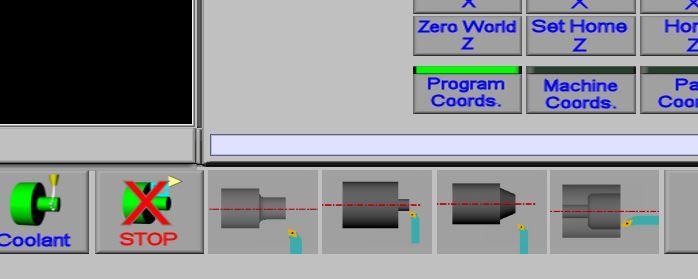

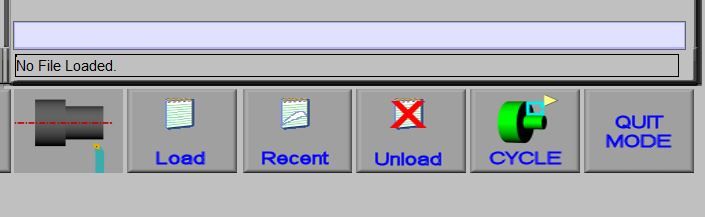

On the opening screen pressing keys m, a, t or d will take you to the Manual, Auto, Tool or Diagnostic screens. In the manual and auto screens pressing q will take you back to the opening screen. On the Tool and Diagnostic screens there is a blue arrow next to the Reset button, this takes you to the Auto page. These few buttons and key presses mean you can move from screen to screen quite easily.

If there has been a change from feed in mm/min to mm/rev then this can be changed back to mm/min by entering G94 in the MDI input window. Change to mm/rev is done by entering G95 in the same way or by having it in the Gcode program. This is often the case when the Gcode is for thread cutting, there is a G95 instruction but not a G94 to return it to mm/min. I suspect that this is what is happening to you. I think you also need to be in mm/min mode to jog if the spindle is not rotating.

Regarding jogging, is the Jog On LED green, if not click on Jog On, is the Jog Inc. LED green if not then click on jog mode to change from continuous movement to jog. If you are on the Auto Cycle screen after the Gcode has run then you need to use the blue arrow button to the left of the Cycle Start button to return to the previous screen with the jog selection buttons on it to do this.

Alternatively if you toggle the jogging screen you will be able to change jog mode and also see a few keyboard shortcuts on some of the keys, these also work when the the jogging screen is hidden. You can toggle Jog Mode by using Ctrl J on the keyboard if you do not want to change screen. And Alt J changes the jog distance setting.

One other thing to note is that I have had the occasional seemingly random problem of the Slow Jog Rate on the jogging screen reset to 0% and this needs to be raised to a rate that suits your machine. I suspect there is some keystroke combination that acts like the rate lowering button that can be accidentally pressed. The first time this happened I spent a lot of time finding what the problem was.

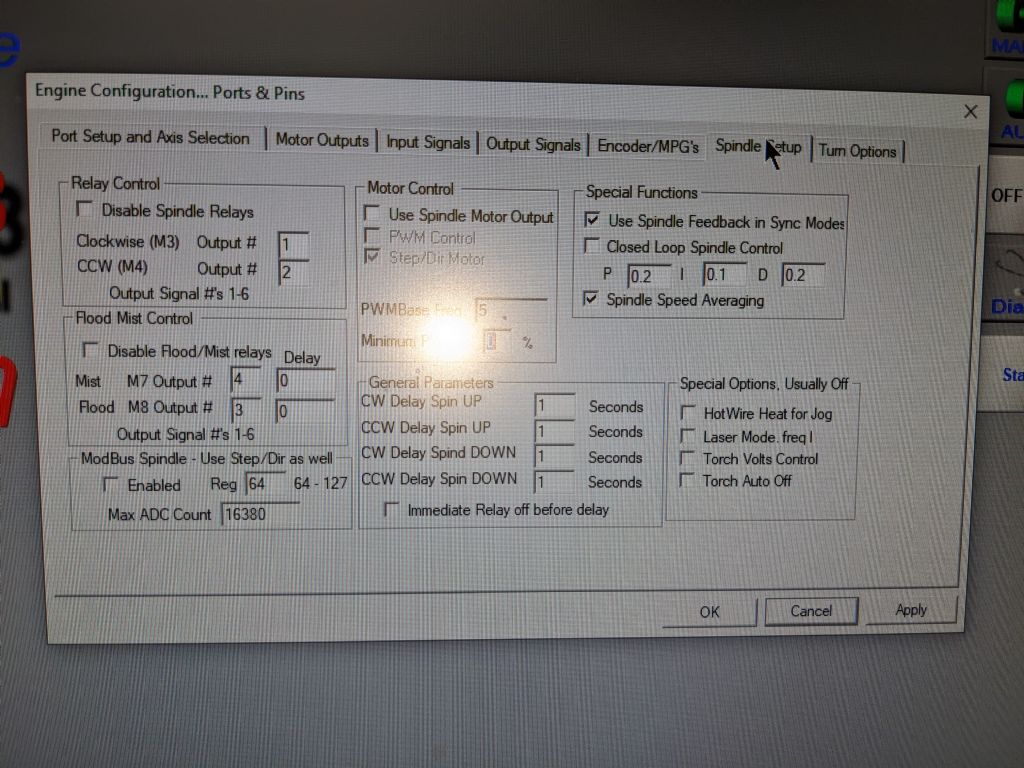

The index pulse caused me some problems when I tried out a different controller. I used a generic board that picked up the index pulse and also showed it working in Mach3. Trying everything to solve the problem of threading not working I reverted to my original Smooth Stepper (I had used it to get CNC working on my mill) and that cured the issue of threading not working. The reason behind the problem is that when using an external controller Mach3 uses the external controller to trigger the motion for threading. This means that the Smooth Stepper works as it is designed to do, threading using the index pulse. The generic board did not work as it did not have the built in ability to wait for the index pulse to trigger the threading motion. The point here is that for threading using Mach3 with an external controller is that the external controller must be capable of working with the Mach3 system otherwise you will be struggling to find a problem that is due to an unsupported board. This is a case of asking the right questions before buying a board. It is not well documented and I found this out by asking a Mach3 group. You need one that explicitly states that it is Mach3 threading compatible or that the vendor says is compatible. That way you have grounds for a refund if it is not compatible. If you still have the Smooth Stepper board I would use it on the lathe.

Martin C

Edited By Martin Connelly on 19/09/2023 08:58:25

Edited By Martin Connelly on 19/09/2023 09:10:10

Tony Jeffree.

Tony Jeffree.