Alan,

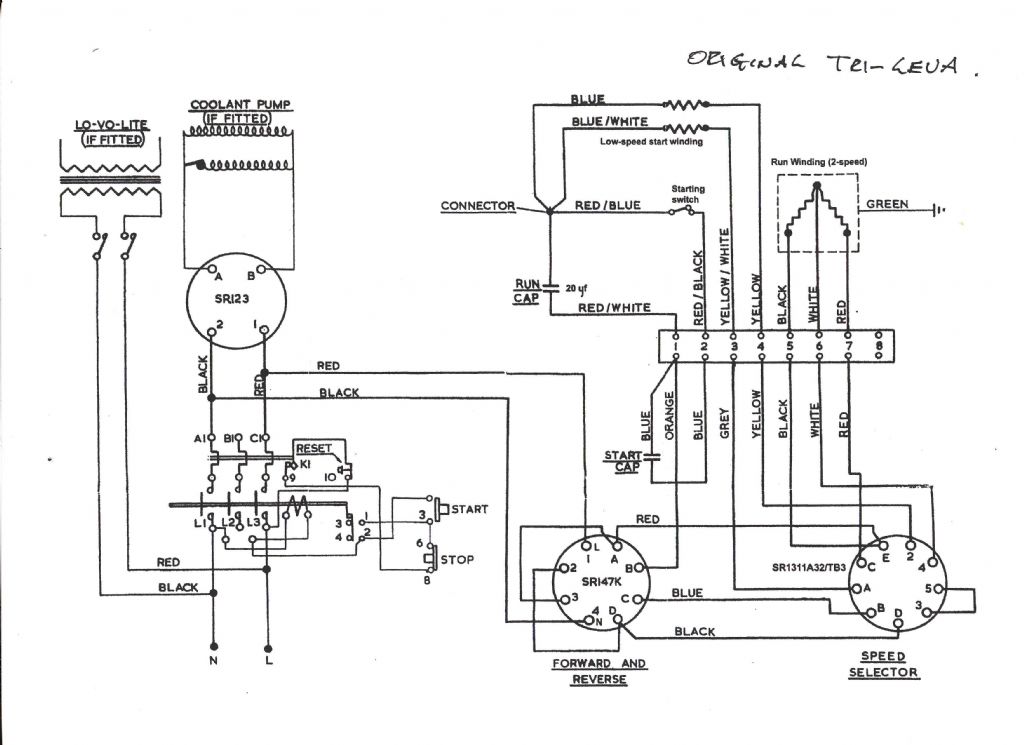

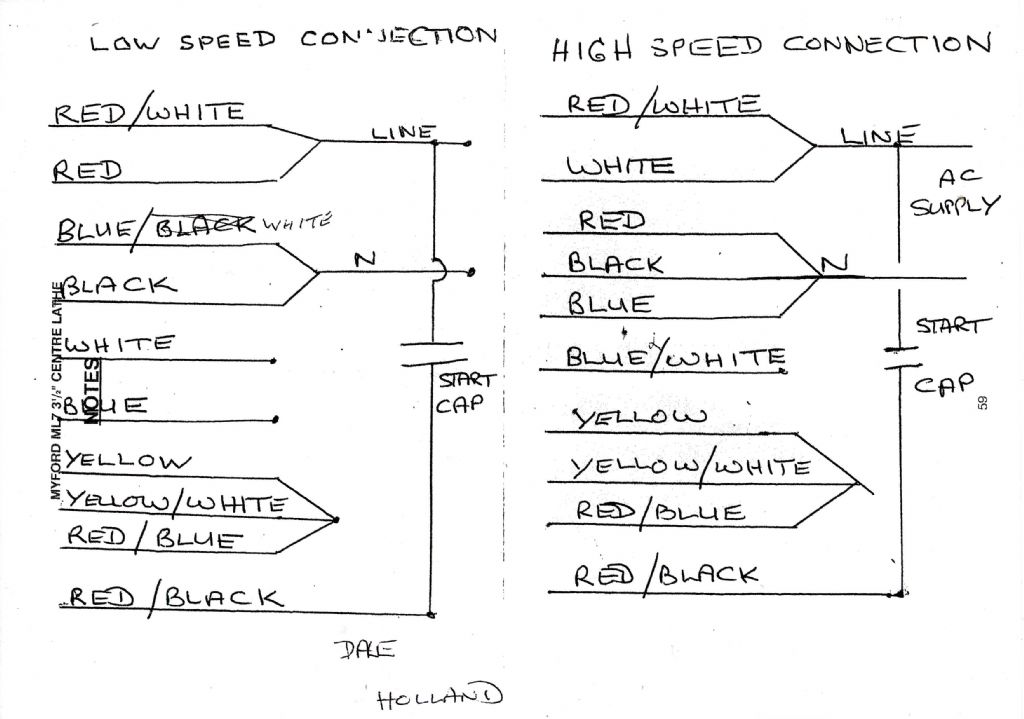

Thanks for replying. I was advised when I bought it that it is a two speed motor and on the drum type switch (fitted into the cabinet) it has forward and reverse with low and high speeds available on both via the selector switch which is clearly original. The motor has 5 leads (including the green, presumably the earth). This should according to the Myford brochure and the trileva plate give 6 speeds and another 6 when the back gear is selected .

The difficulty is that the Myford ML7 and Trileva manual doesn't give any wiring diagrams appropriate for a two speed motor and local sparks I've spoken two say it isn't possible on a 1ph motor! However, I have found other data on the net which says it is though and I do have the physical proof of the machine!

The trileva works fine on the lower speed though but I simply cannot remember if it worked on all 6 speeds when I bought it. I've now decided to replace the conector box with one which permits easier connections visibility (the original was small and difficult to see if they were made correctly) and will wire it up the same as it was just to check the connections were made correctly.

For anyone more knowledgable than me with motor electrics, the motor leads are red, black, brown, yellow and green. The motor has a single capacitor and might be a Crompton although it has no nameplate. . It has 4 terminals Z, A, ZA, T and earth. which appears to be the Crompton designation and the manual for the standard states these are start, running, running and start windings respectively.

All I can think is that the complicated switch somehow links different windings together to get the 2nd motor speed…. Arghh my brain hurts!

john fletcher 1.