John Stevenson’s comment about 60/63 being used “instead of” 120/127 might, for some, leave the impression that the approximation comes about because 63 is the closest integer to one half of 127 and is, in comparison, compact and hence more convenient. But not so – the error would be one part in 126 (or 127 for their reciprocals). As stated in other posts, a 127 tooth gear will produce a mathematically exact metric pitch on an imperial lead screw, being the exact number of mm in 5 inches and the lowest integer pair that expresses this exact relationship.

For metric pitches using an 8 tpi leadscrew, the exact desired conversion ratio is 25.4/8 mm per one leadscrew pitch, or 25.4/8 = 127/40 = (127/100) x 2.5 = 3.175 (exactly). It just happens that this is closely approximated by 200/63 = (80/63) x 2.5 = 3.174603…, just 1 in 8001 smaller (12.5 microns per 100 mm, or 0.0005” per 4".

Notice though, that whereas the 127 tooth gear forms the numerator (a driven gear), the 63 tooth gear forms the denominator (a driver gear). It is not performing the duty of an approximate 127 tooth driven gear (i.e. not 63 x 2 approx. equals 127). The actual comparison is between the ratios 127/100 and 80/63 (ignoring the 2.5 common multiplier).

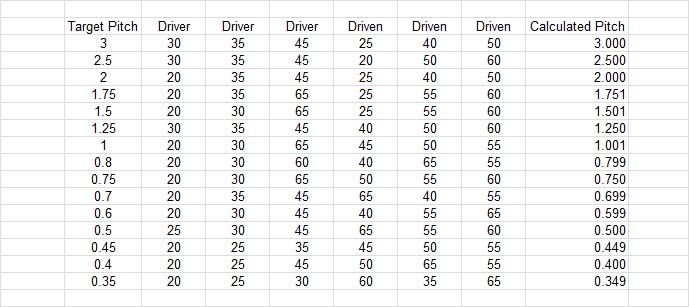

Since 21 and 3 are factors of 63, a 21 tooth gear can also serve as a driver, with the factor of 3 formed by other train gears. For example, a 1 mm pitch from an 8 tpi lead screw requires a lead screw to spindle turns ratio of 63/200 = for example (21/40)·(30/50), or, as per Roderick's table, (45/40).(21/75)

Edited By Rodney Entwistle on 14/01/2016 06:36:48

Edited By Rodney Entwistle on 14/01/2016 06:37:28

Edited By Rodney Entwistle on 14/01/2016 06:58:45

Edited By Rodney Entwistle on 14/01/2016 07:00:14

Neil Wyatt.

Neil Wyatt.