As luck would have it I've just crated up my ML10 for a house move so can't check it, but I do have the Myford owners manual to hand which has the section drawings and parts lists in the back. On section D-D that shows the upper shaft (for the carriage handle) as part no 228, and the lower shaft as part no 122.

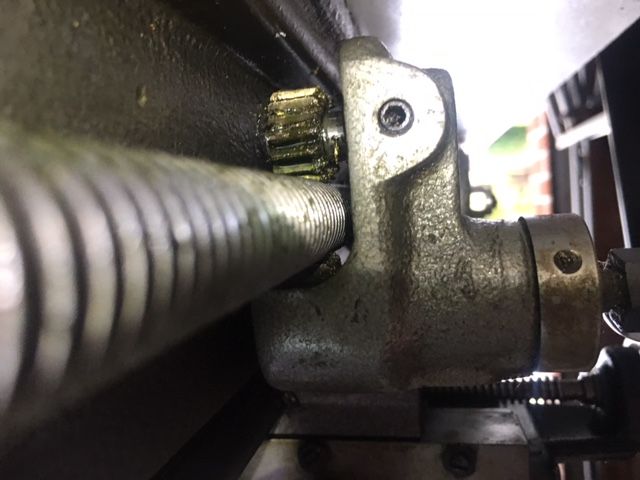

No. 228 is the handle spindle so rotates and does not have any eccentric adjustment, but does have a groove in it for the retaining grub screw (part no. 120), visible immediately behind the carriage handle as Roger mentions.

No. 122 is listed as 'eccentric' and appears to be intended to be rotated to raise or lower the lower gear to engage with the leadscrew. If set too low it will allow the leadscrew to deflect downwards out of engagement with the carriage handle spindle gear and may be the cause of your problem – worth checking. No. 122 is drawn with a groove in it for a retaining grub screw, part no. 124, which is inserted from the right hand edge of the apron.

If adjusting 122 doesn't work then have a good look down behind the apron – I was surprised to find large amounts of swarf down there on mine, which could easily fill between gear teeth causing problems. Worth a look.

Hopper.