I had to take the apron off my lathe yesterday. An opportunity to take a picture of some modifications. I also discovered that the bent washers(!) keeping the clasp nut gib in place were a complete waste of time, as it was badly out of alignment.

I took everything apart, deburred the gib strip and lightly refinished it on some wet and dry over the surface plate. I also removed some burrs on the cam plate.

I then made a strip with a 20-thou step (measure your own lathe) to replace the pair of washers that clamp the gib strip in place. There are two adjustments for the clasp nuts – three screws through the side of the apron that adjust the gib, and a fourth screw up through the bottom of the lower clasp nut. This should be set to allow the correct degree of engagement of the nuts with the leadscrew. Interestingly Ian Bradley made a similar modification to his Myford 7-series lathe, although he left out the locknut as his tap was dodgy and he got a stiff thread!

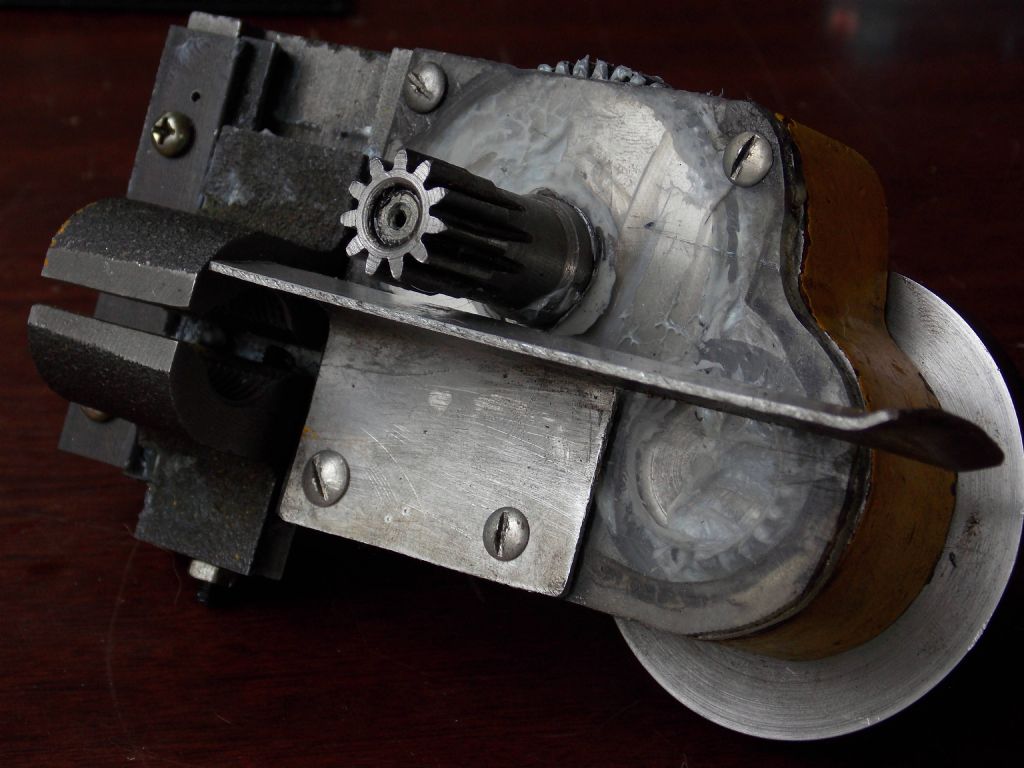

These pictures show the mod:

This final picture shows two long-standing modifications. The clear cover for the gears is made in two laminations, as the gears are slightly proud of the back surface of the apron. Without this modification you will continually be getting frustrated by tight spots in the saddle handle action to due swarf in teh gears.

The simple swarf guard is just cut and filed and then bent up from some 16-gauge aluminium sheet. It isn't perfect, but it keeps lots of swarf off the leadscrew in the area of the clasp nuts.

The white stuff everywhere is Finish Line teflon grease. I doesn't seem to dry out as badly as moly grease and is a lot 'cleaner' (at least it doesn't eave tell-tale grey marks on the towels…)

I'm not sure why the lighting on those pictures is so perfect. Perhaps it's vbeacuse I set the digital to 80ASA, or it was just the diffused, overcast daylight in our conservatory, but it has captured the metal tone and texture wonderfully.

Neil

Sub Mandrel.