From a previous thread :

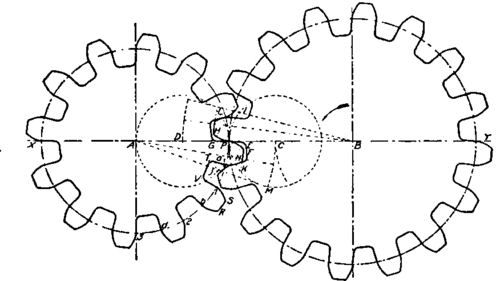

One of my college lecturers giving the Theory of Machines course had some very large Perspex gears segments – just a few teeth but accurately profiled . Watching the interaction of pairs of these gear segments at a size big enough to see what was going on was very instructive indeed .

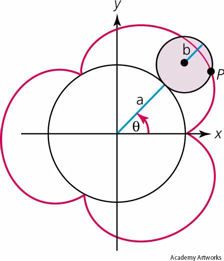

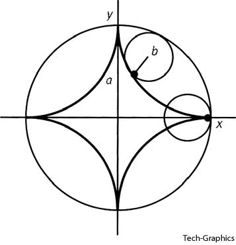

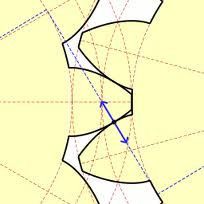

He had examples of involute gears of different pressure angles and also cycloidal , lobal and conformal gears .

Apart from just seeing how the teeth interacted it was possible to see how the gear meshing action varied with depth of engagement errors .

Anyone that thinks a gear is a gear and they all work the same way would be astonished if they tried a similar experiment for themselves .

Two further things that the lecturer pointed out by a simple additional demonstration with a segment of a disk of Perspex were that in the local zone of contact of the various types of gear teeth they all had more or less the same curvature and that it was the local flank angle of the gear teeth that made the meshing gears different in action and more/less sensitive to depthing errors .

More :

Clock gears only have to index – even in large clocks the forces involved and the amount of power transmitted are very small . There is wide choice of suitable shapes for clock gear teeth – many early clocks and calculating devices had just simple peg teeth . The triangle shape also works reasonably well after it has been 'run in' – basically the teeth rub themselves into conformal shapes .

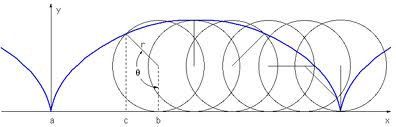

The cycloidal form has several possible origins :

Trial and error – generations of clockmakers tried this and that and found something that worked .

Scientific – Some early areas of mathematical study were conic sections and celestial mechanics and most astronomers and scientists would have had a profound knowledge of both . All early celestial mechanics was based on the cycloid and some sharp minds of the day probably saw the similarity between planetary motions and the interactions of gear teeth and used their insights to make practical gears for clocks and instruments . Knowledge of conic sections allowed these gear profiles to be understood further and defined in an easier manner for practical use .

Religious – Hard to understand now but life for many academics years ago was dominated by religion – not only by the Christian religion but also by the Islam , Bhuddist , Hindu and many other religions . Only a few hundred years ago the motion of ' The Heavens ' was seen as ' Perfection ' ie immutable and not to be questioned . Early mathematicians and astronomers accepted this and fitted their maths around it – hence the cycloidal model of the sun and planets . As far as anyone could tell it was correct anyway – the model worked quite well for predicting the motions . The cycloid itself , since it defined heavenly motion , was itself seen as ' Perfection ' and it was but a small step from there for religiously minded people to consider the cycloidal motion as the pinnacle of mechanical nicety and use it for gears in their clocks and instruments .

More :

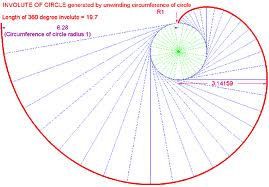

Power train gears not only have to transmit higher forces and powers – they also have to do so synchronously – as nearly at constant speed as possible for many applications . The involute was deliberately derived scientifically for this purpose .

I'm pretty sure however that eary millwrights would have observed that wooden cog teeth and as cast iron gear teeth wore themselves into something like involute shapes after a few years use and they may well have made new teeth something like the correct shape long before the scientific derivation .

Regards ,

Michael Williams .

Andyf.

. But I just need the screw cutting gears as i need to put power feed back onto it also I want to make my own set as a gear is something ive never made before and I want to learn how to do it and this would be perfect for it.

. But I just need the screw cutting gears as i need to put power feed back onto it also I want to make my own set as a gear is something ive never made before and I want to learn how to do it and this would be perfect for it.