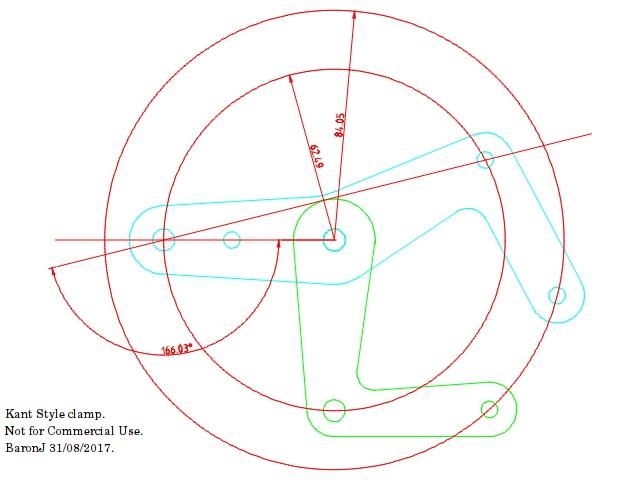

Way back when I started scratching out my DIY version of the Kant-Twist / Crab clamp on the backs of envelopes I reckoned the riveted pin and spacer construction was a major potential weak point if not precisely made. Seemed to me that it was one of those things that could only be done accurately and precisely on a production line with professionally set up tooling.

Getting things sufficiently precise with joint and gaps tight enough to ensure that things wouldn't try to twist whilst still being free moving looked to be a nightmare by one-at-a-time methods with simple pin and rivet construction.

Ended up with various combinations of welding, pressed in spacers having washers on the outer ends so the riveted over through pins wouldn't be hammered down against the arms and other associated exercises in misguided creativity to properly support the joints. None of which gave that nice warm feeling of working really well first time out.

After a week of lunchtime efforts I concluded that I didn't want some that badly and would be unlikly to seriously worried by not having any. 30 or so years on that turned out to be about right. Maybe half a dozen jobs where they would have been seriously better than what I had.

My then boss reckoned the reputation was mostly "American Hype" and flop-slop was inherent.

Clive

Tony Pratt 1.