Posted by Hopper on 16/11/2019 10:44:24:

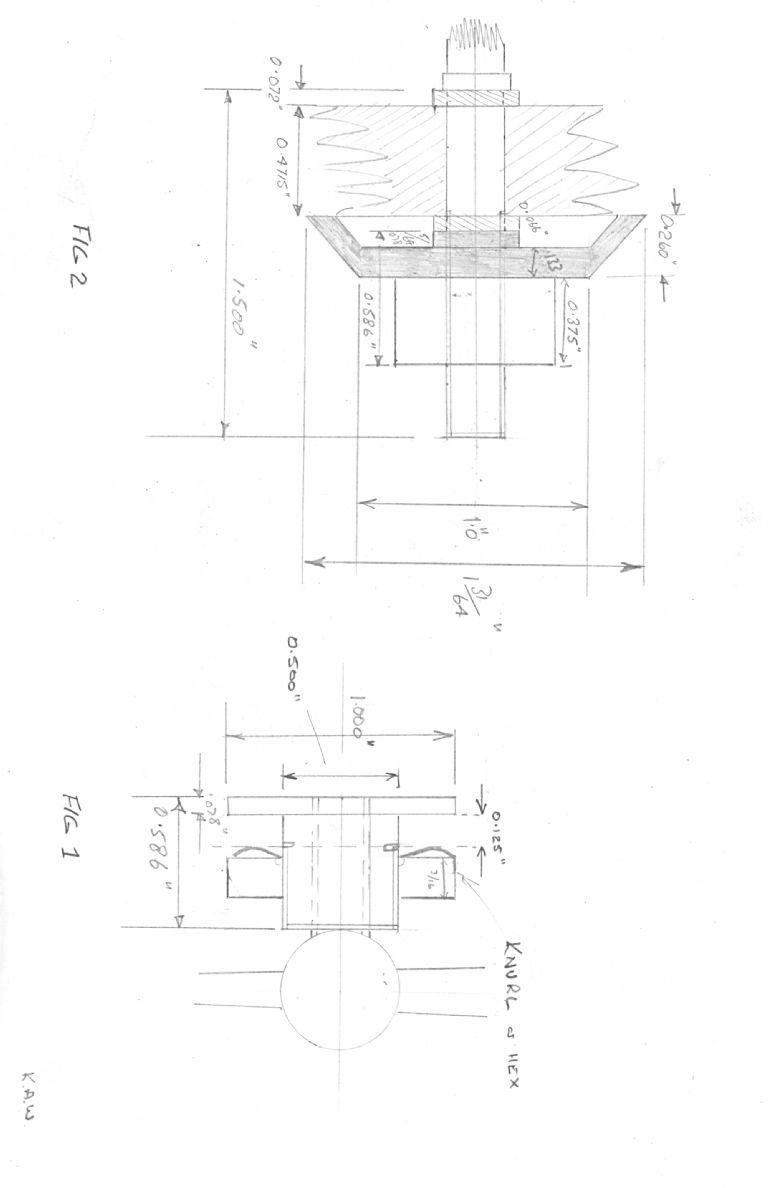

YOu hold the dial with a spanner on the two flats. Then turn the ball handle anti clockwise so it loosens off. Then you hold the feedscrew still and tighten the dial until end float is taken up. Then you screw the ball handle clockwise until it locks the dial in position.

Given your beginner level of mechanical experience, you should hold off from disassembling your lathe any more than is absolutely necessary to get it running. It is not a beginner project to put it back together correctly from scratch.

Yes you can get lengths of feed screw blank. It is an Acme thread. 10 TPI. Diameter, I forget but you can measure that.

If you want to convert to metric, you will need instead to buy lengths of metric trapezoidal threaded bar. Pitch I THINK wouild be 1mm But check that with someone who has a metric Myford lathe. So long since I worked in metric I don't remember.

You might find some metric trapezoidal threaded rod on eBay, Aliexpress etc. Otherwise there are several suppliers in the UK who have been mentioned on the forum before so a bit of searching around past threads should find them. But you will need to be able to use a lathe to turn the ends down and thread them to suit the dials and handles etc.

Another old trick is to cut the threaded section off the feedsrew and turn it around and reattach using a spigot etc so the unworn section of the feedscrew is now in the high-use zone. Probably more effort than it is worth these days.

Oil splatter from these lathes is not a problem. It's normal. That's the way they did things back then. It does not indicate anything wrong with the bearings. OIl will come out of a brand new bearing because there is always clearance between shaft and bearing — to let oil flow through! A strip of rag tied around the gap between chuck backplate and the headstock bearing will stop most of the "fling". And don't stand in front of the chuck. Work standing in front of the carriage or even a bit further toward the tailstock. Keeps you out of the hot swarf zone somewhat too.

To test the bearings, hold a length of solid bar or pipe in the chuck, about a foot (30cm for you metric types) long. Grip the end of the bar and try to move it up and down and side to side. Measure the amount of movement of the spindle right at the headstock with a dial indicator. Or if you have no dial indicator you might get a rough idea by holding a finger on the spindle and bearing and feeling for movement. Should be about one thou (two or three hundredths of a mm) of movement. IE only just discernible by feel and that's all.

Edited By Hopper on 16/11/2019 10:51:29

Its all good, I think I was just being overly cautious. The handle was just on too tight. I managed to unscrew it easily enough and take a better look.

Just as i guessed, the washers were added to pull back more thread to catch all the way down since half the thread on the nut is missing and the unthreaded part at the end of the feedscrew would not catch.

Im going to have to rebuild both slides as a minimum.

It seems to be the most need of attention to make the lathe usable.

Good news is that I think the rest of the lathe is in fairly good condition for its age, does not seem to be heavy wear on the bed and minimal wear on the bearing from what I can tell.

Oil splatter, thats good to know its normal, yes where i stand it does not hit me, but it leaves a trail on the walls and floor so I want to address this if possible.

Have made a few cuts on bronze stock and even in the poor state of the lathe, currently things seem to measure up OK.

Right now the lathe is not very usable until i sort out the slides anyway.

Will do the test with a dial indicator to check the bearing wear as you suggest.

Was looking on myford site and yes the imperial leadscrew is 10TPI 3/8 diameter.

the metric feedscrew is quoted as Threaed 3/8" x 2mm pitch

I may just ordering everything from myford, but ive got a friend who can probably machine these easily enough for me which would be useful.

One other question, is with the apron assembly, are you supposed to lock down the power feed lever to stop it moving when making cuts?

I find the saddle will move across the bed if making an end cut with the top slide as I move the cutting tool into the stock. I found locking down the powerfeed lever would help, although i question whether or not it might need tightening up?

ega.