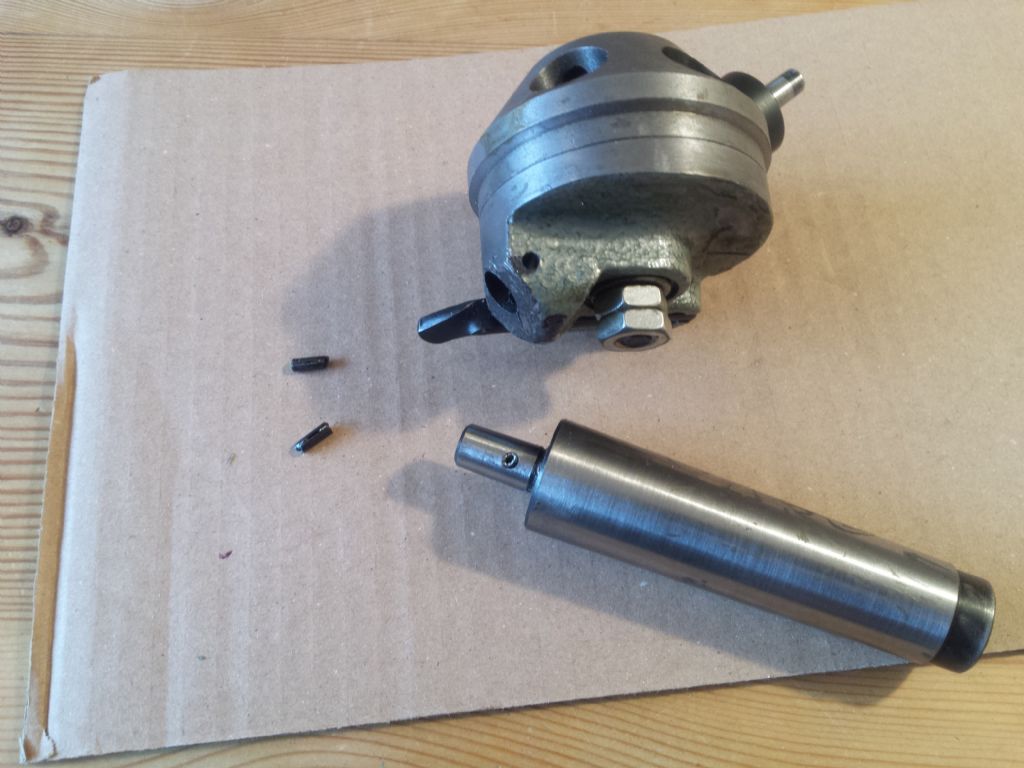

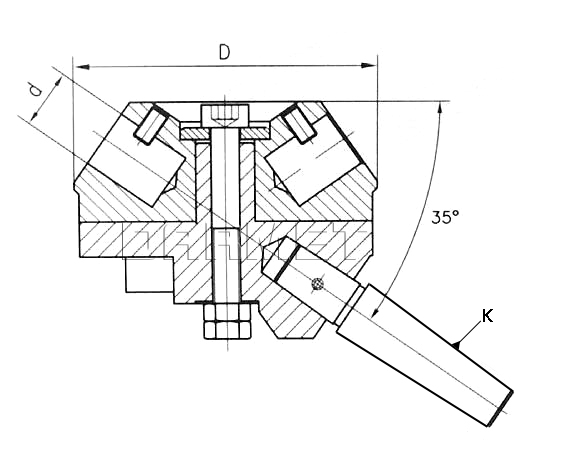

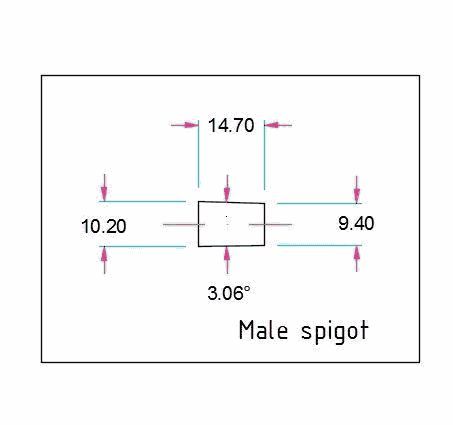

Is this Morse shank removable?

Is this Morse shank removable?

- This topic has 29 replies, 11 voices, and was last updated 12 December 2018 at 15:39 by

not done it yet.

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

Latest Issue

Newsletter Sign-up

Latest Replies

- “Your Sketch Is Not Closed,” says Alibre Atom, “So tough!”HERE?ERE?

- Clock gear cutting needed or advice in setting up from scratch.

- How to balance a cup grinding wheel

- Unusual Crow Bar Type Tool? Fire Brigade?

- Instrumatic Hardness Tester

- Thread restorers

- Bridgeport ways and wear

- smokeless cutting oil

- Smart Meter Change-over Problems

- Amadeal lathes – Any good??