Haydn –

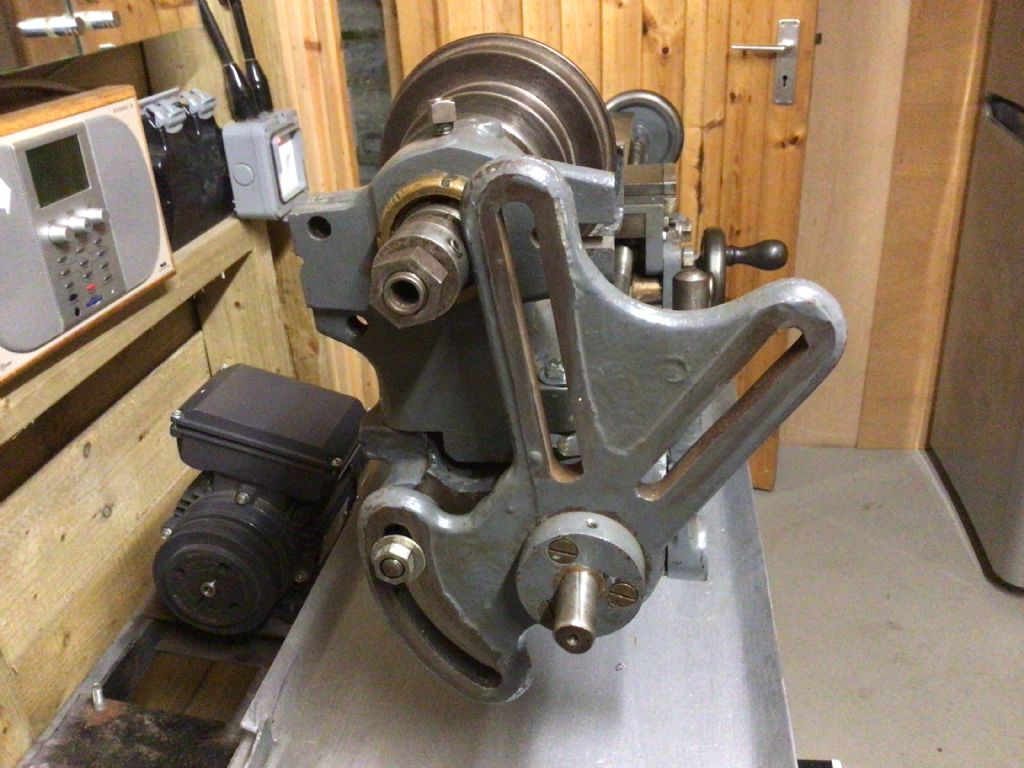

"Back-gear" is a low-ratio gearing on the headstock itself, used when extra low spindle speed is necessary, especially in screw-cutting.

Only, your lathe has lost it, unless it is all in the assorted bits that came with it.

The holes in lugs on the back of the headstock show where it may have been fitted -but the spindle seems to have nowhere for its back-gear wheels.

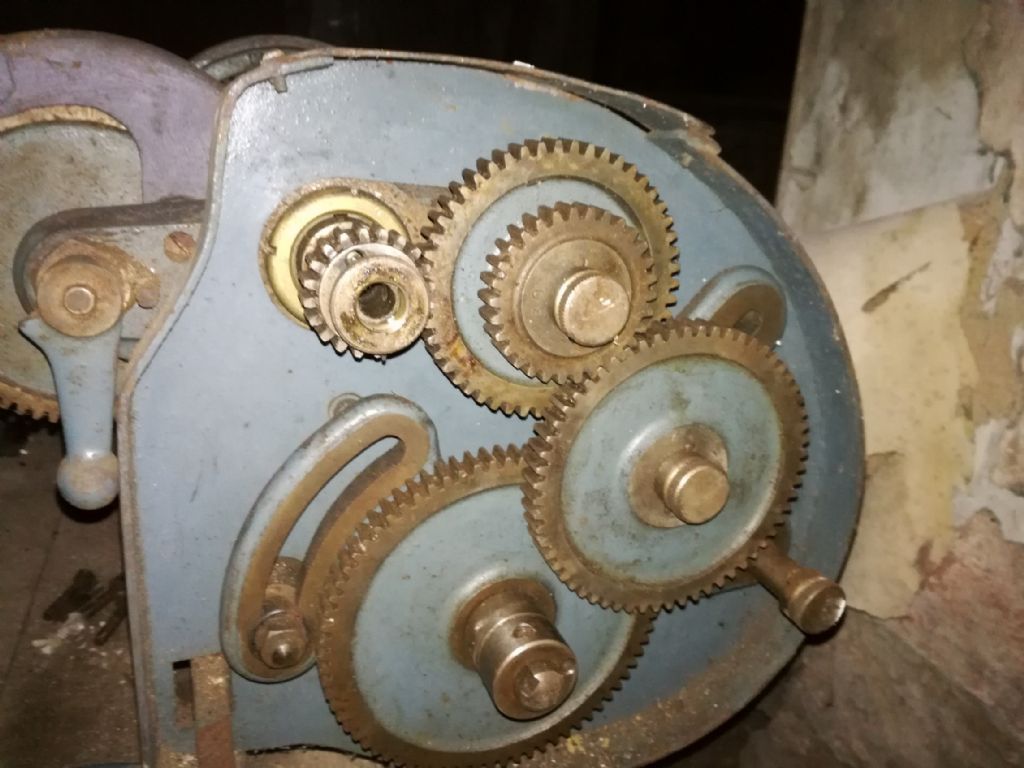

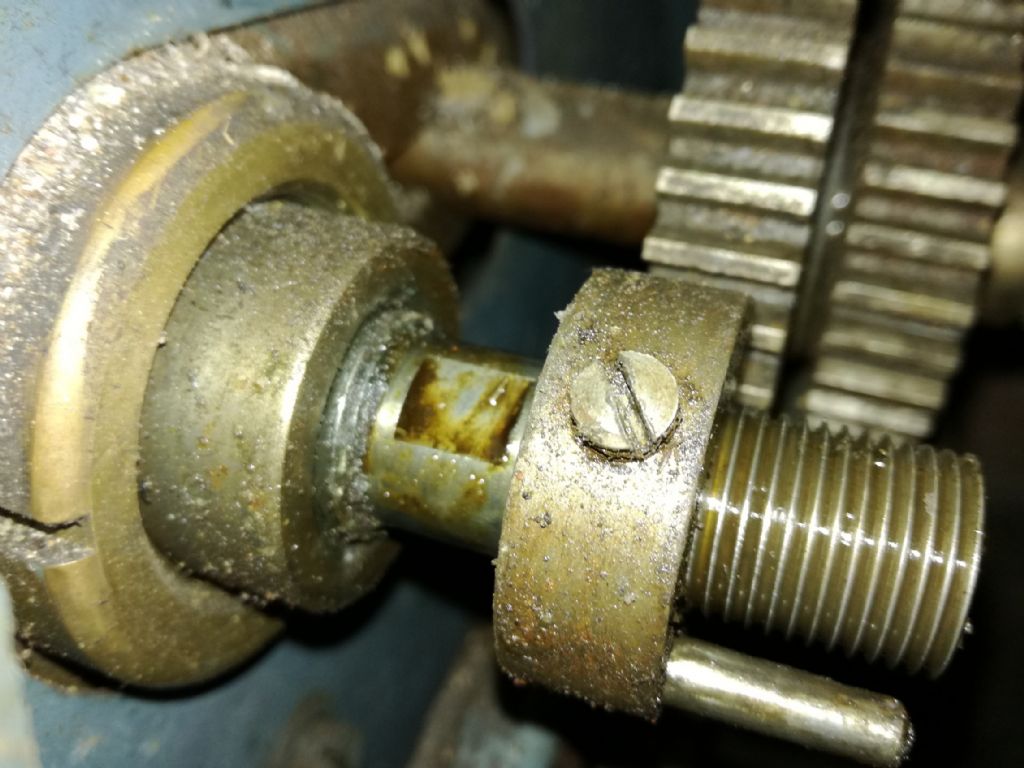

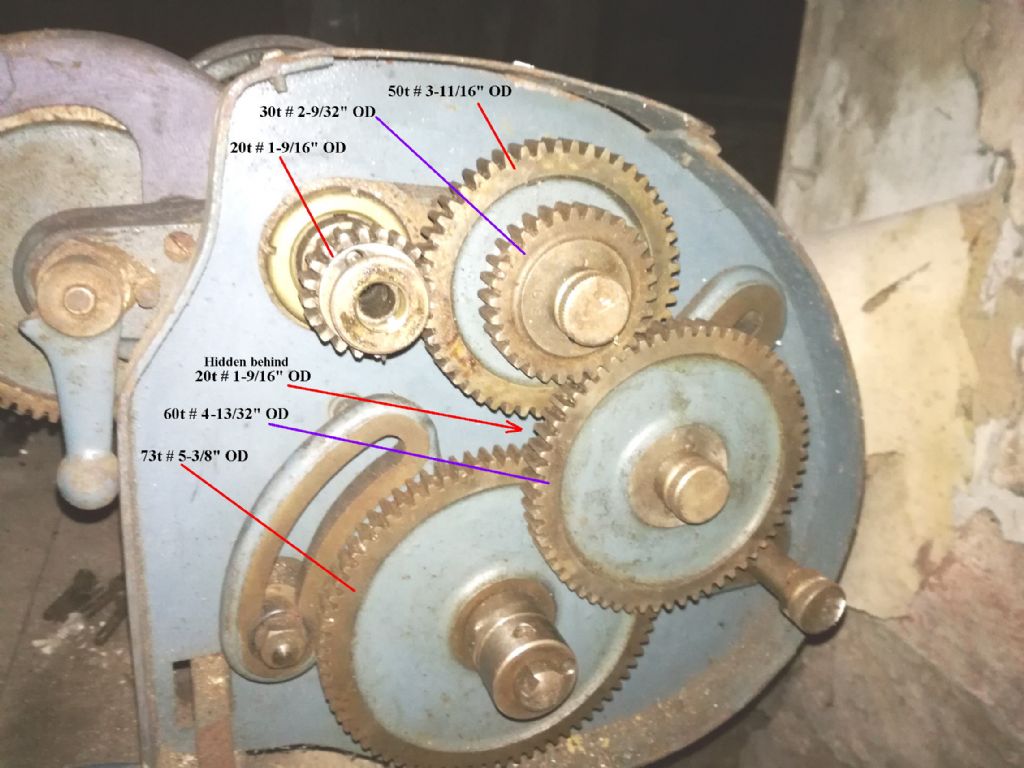

It would show as a large gear on the chuck end of the spindle, and a smaller one at the other end, but both inside the headstock. They would have been matched by two gears on a shaft mounted on rearwards extensions (bolted on, on this machine) of the headstock; with an arrangement for engaging / disengaging them, and for disconnecting the larger spindle-gear from the spindle to allow it to work.

.

That separate assembly with the pulleys is the Counter-shaft, acting as the primary speed-reduction from the motor, and carrying the speed-change pulleys. With the back-gear lost you could replace it by additional belt-gearing. It would be feasible to make a new back-gear, but not easy, and a lot of work – then you'd need make up a set of change-wheels either with additions fully-compatible with the existing ones, or all-new.

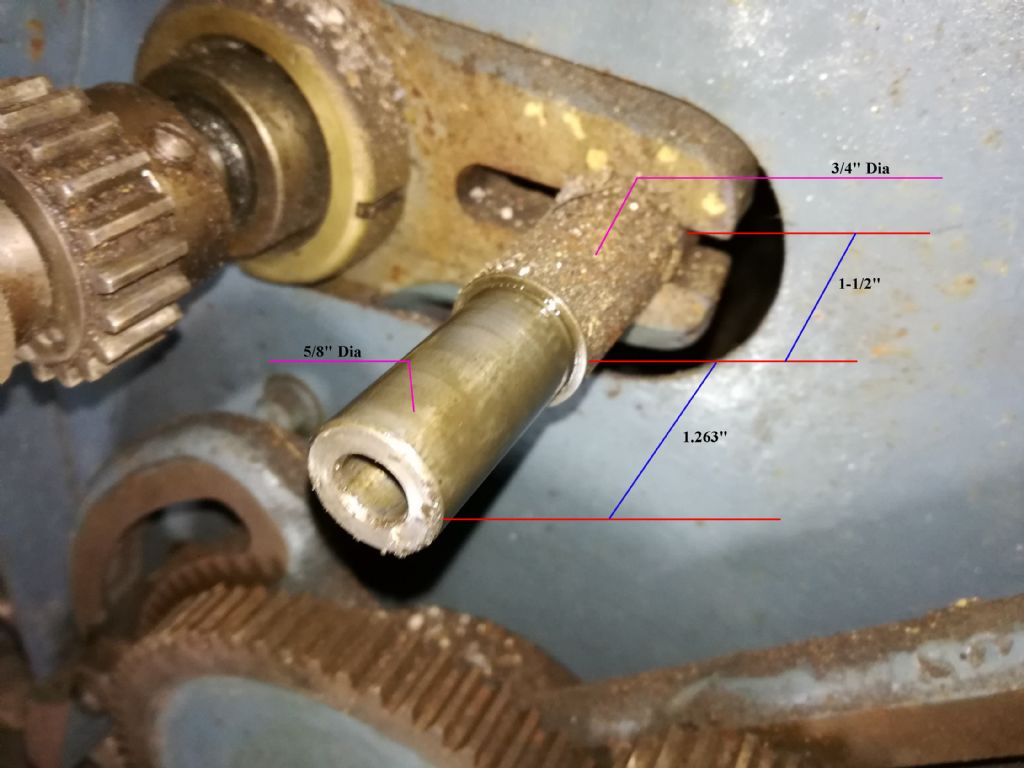

Unless you intend cutting many, long, large threads, it is perfectly possible and indeed not unusual, often even advantageous, to do so by slacking the drive-belts and rotating the spindle by hand-crank. Remember to remove the handle before using the motor again! Myfords do sell a mandrel-handle for their lathes but it won't necessarily fit this one. Various designs for making them are in the model-engineering literature, and can be adapted to the specific machine. The basis is an expanding collet a bit like a masonry-bolt.

.

It is sad to see an old lathe damaged by some previous owner, as appears here. It is very hard to imagine why he removed (and lost?) the back-gear, and cut off that lug on the front of the headstock. If it was to allow fitting a new belt-guard, the motive is good but the method poor!

I think the forked lug still at the other end was for a reversing-pinion used when cutting left-hand threads.

Nigel Graham 2.