I assume actually you are asking for the step by step procedure on how to do it as this is in the 'Beginners' section. If not – don't bother reading this post

How long is the travel on your compound slide? If it's long enough to cover each of the tapers this is what I'd suggest you do:

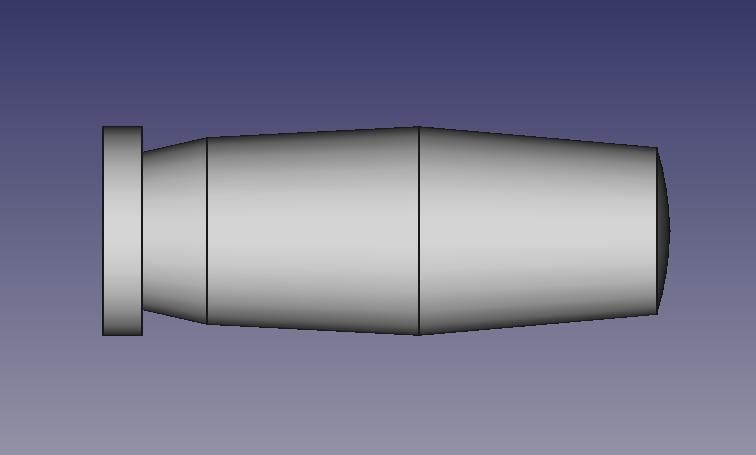

Cut two rods about an inch over size. Put one rod in the chuck. Set the compound to the correct taper angle on the right of your model (it will be parallel to the desired cut, with the tool at the headstock end and handles at the tailstock end, the left end of the compound will be further from the lathe axis tan the right side. Furthermore, wind it towards the headstock as far as it'll go to zero the travel).

Turn to diameter and face the end of the rod off. Now move the saddle towards the chuck the distance of the length of the main taper (horizontal distance in your diagram above). Engage the saddle lock and now only work using the compound slide and saddle cross feed. NO axial feed.

Wind the compound slide out so the tool is on the tailstock side of the end of the work, and feed the saddle in until the tool just nips off the corner of the rod when using the compound feed. Now feed in a bit more using the saddle cross feed, and cut the work using the compound feed. Continue this until the tool just touches the work when the compound feed is at the extreme end of its travel towards the headstock.

Unlock the saddle and repeat above 2 paras with the second handle.

Unlock the saddle. Now wind the compound slide in towards the headstock as far as it'll go, and change the compound angle to the angle of the taper on the left of your model. This time the left end of the compound will be nearest the centreline. Rotate the toolpost on top of the compound slide so it's parallel to the lathe axis, and zero the tool at the tailstock end of the work using the lathe axial feed. Now move the saddle towards the headstock the amount of distance between the end of the work and the END of the second taper. Lock the saddle here against axial movement. Turn the lathe on and start cutting by feeding in on the saddle, and getting the compound to do the actual cutting work. Once the taper is long enough, stop and repeat the process with the second handle without altering the compound angle.

Now, finish with a file/emery or whatever.

Finally, set the compound angle to zero & part off each handle.

Hope that explains how to do what you have shown, bearing in mind I've assuming you are a total beginner and possibly barely/if ever tried taper turning with a compound slide.

Regards,

Richard.

Edited By richardandtracy on 02/03/2017 15:36:45

SillyOldDuffer.