Despite assistance I think I'm out of my depth on this one!

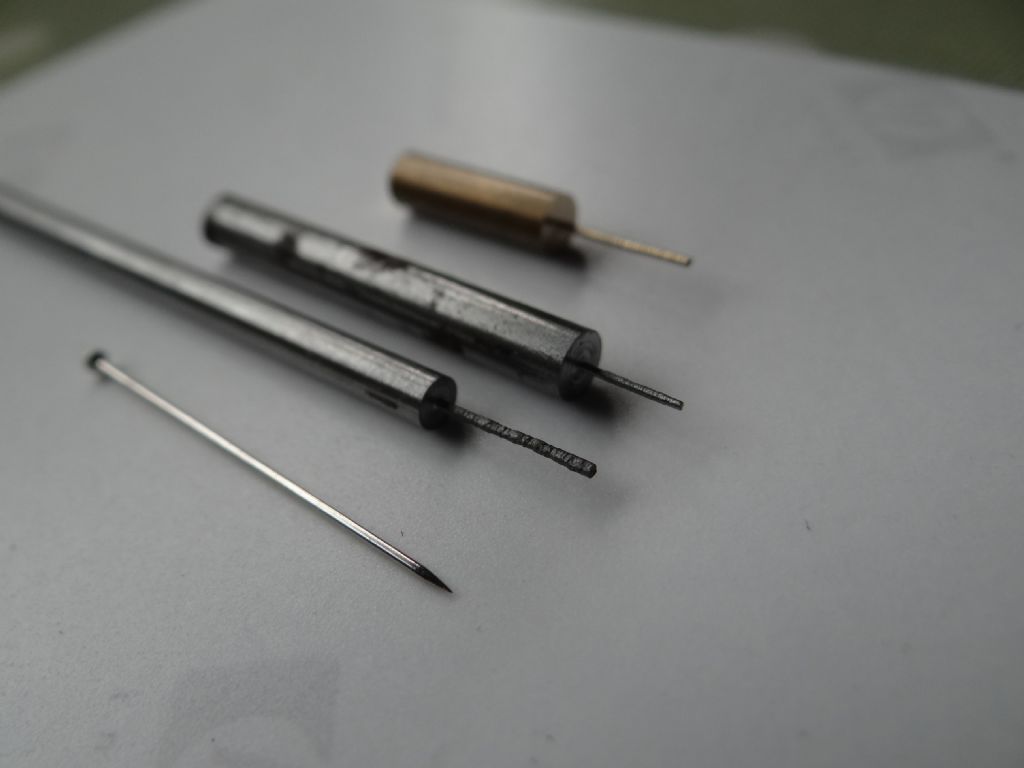

Made progress cutting thin rods, my technique has improved. The material matters. Not difficult in brass, tricky in mild-steel, awkward in silver-steel. I can turn down to 0.5mm without too much bother, less than that and the rod becomes fragile and breaks easily. Photo has dressmaking pin for scale.

I haven't tried a specially sharpened HSS tool yet and hope that will fix the poor finish.

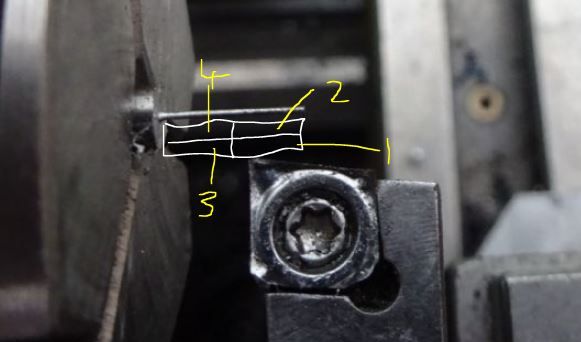

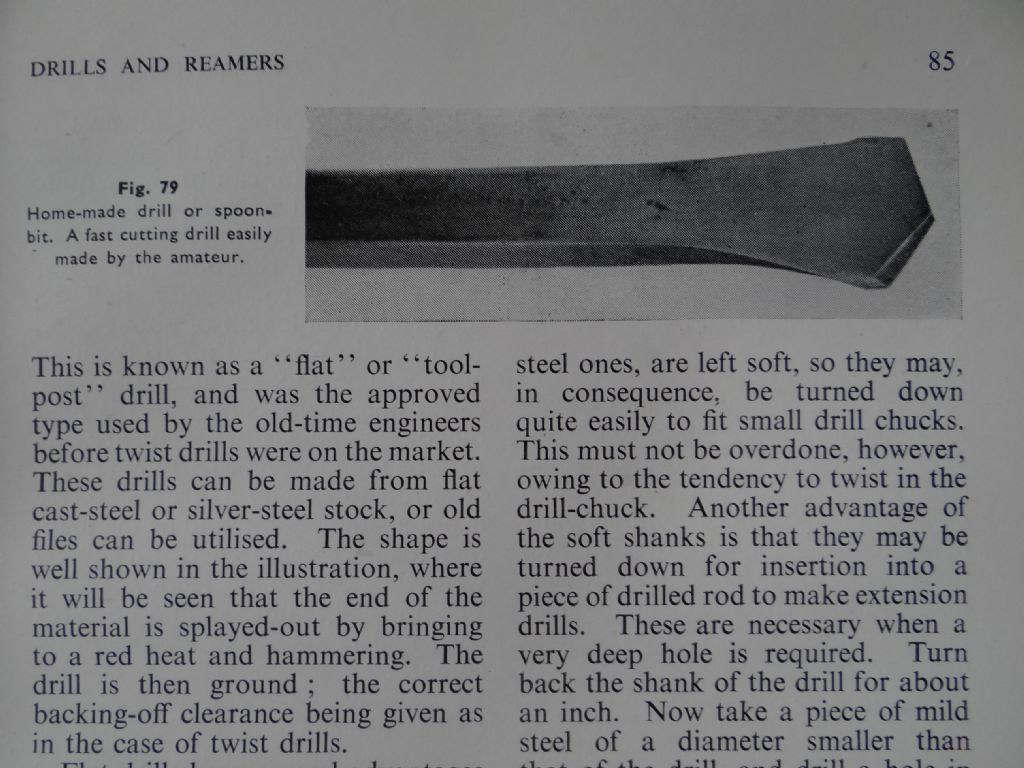

So far so good except I now need to drill deep holes through brass with one of those spindly rods. The plan was to make a spade or spoon bit drill as per Sparey:

Seems simple enough, and Sparey says "easily made by the amateur". With help from Michael Gilligan (thanks) I was able to make a crude drill on this pattern from 3/32" (2.4mm) steel, and to drill a hole in brass with it. Hard work, about 10% as efficient as a twist drill. No doubt the cutting rate could be improved by more careful grinding but this type of drill needs more force than a twist drill, doesn't clear swarf at all, and I despair of drilling a hole 0.3mm diameter hole 10mm deep with one.

More bad news, I struggled to produce a decent drill tip at 2.4mm diameter. My fat fingers and poor eye-sight made heavy weather of the job. Now I've tried it, I've no idea how to scale the process down to 0.3mm. I have to heat the rod without melting it, flatten the end, and then grind a pair of relieved cutting edges without breaking a delicate sliver of metal. I am intimidated!

Final blow, I dropped the prototype drill and it's joined my missing Biros in another dimension. Woe is me.

Making fine drills in a home workshop must be possible, any ideas?

Dave

PS Jason's suggestion that Neil cover this in 'Lathework for Beginners' is excellent. Full of good advice though 'be prepared to use your ingenuity' didn't work for me as I've lost it. Neither did 'Turn off your phone!', though at least I managed that without breaking anything…

Michael Gilligan.

Michael Gilligan.