John ( Pace), Thank you for the time you have taken to explain and help me along. I have a much better understanding and the concept of not eroding away the teeth with my setup is also better understood. Thanks to everyone who joined in as well – this stuff is not rocket science, but appears so while the fundamentals elude one!

The penny dropped here:

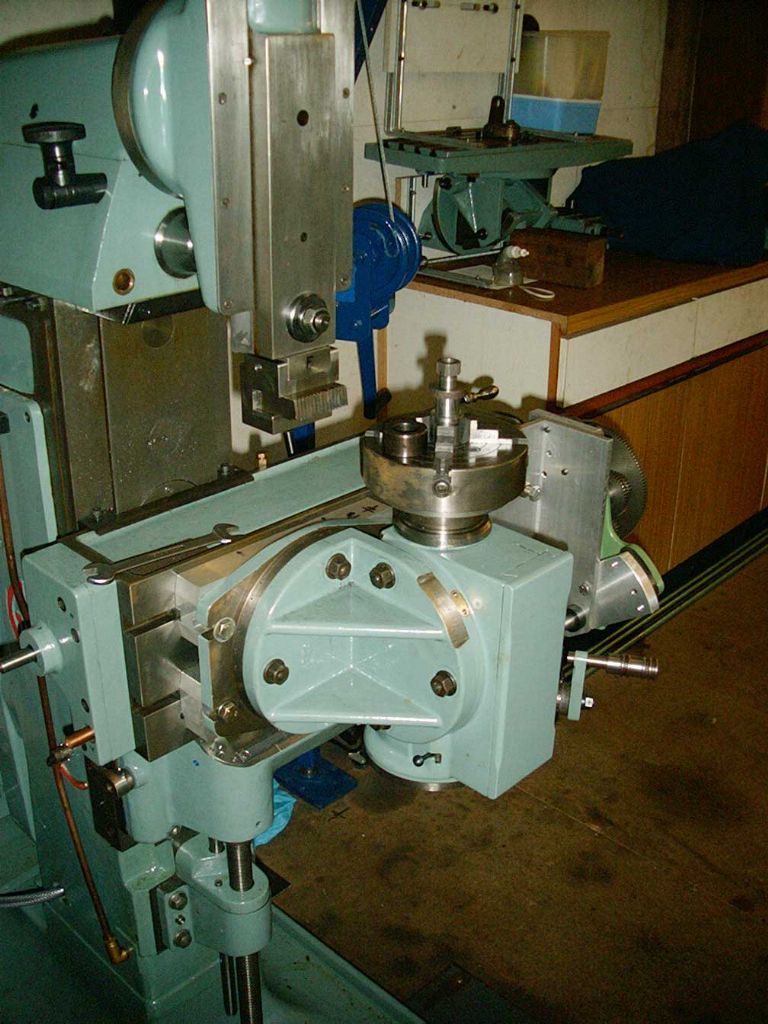

The 2nd photo here is a worm wheel that would be suitable to

transmit power cut with a 0.9 module hob and is overcut

the calculation for the size was about 53 1/2

tooth but was cut at 56 tooth ,the target tooth count was 60

but the tooth shape was becoming too degraded on a test piece

and 56 was about as far as i was prepared to go to be safe.

The difference in the shape of the teeth can clearly be seen

in comparison with a tap cut wheel.

Since in my first runs I did erode away the teeth, but realise now that was because my ratios were way out for that tooth pitch and blank diameter – the teeth did not walk over each other, as I thought was happening, but per you explanation above, they simple began to thin out to the point of vanishing…

I am going to make up a handful of scrap plastic blanks , start with the computations and go and experiment to see what actually happens.

John, my application does not require any appreciable power in the transmission – zero backlash is very critical though. That is why I considered a screw thread type tooth profile as appropriate – esp as I can adjust the worm shaft easily to squeeze worm and gear together, forcing the flanks of the teeth of worm and wheel to ride hard on each other, hopefully eliminating backlash. I am also banking on that form providing some protection in the event of things going awry while in motion and the arm being forced into a hard stop – hopefully the worm wheel teeth will just give way..

Before I started with all this, I read through Ivan Law's ' Gears and Gearcutting' – but did not absorbs what I should as I did not know what I did not know… Having read Chapter 7 thoroughly again I have rekindled confidence..

Thank again to all, very much appreciated.

Joe

Phil P.