Hi Jamie.

As a relative newbie to all this machining malarkey myself, I can sympathise with your frustration. I would like to take this time to give you a few pointers that I have learned since getting my milling machine.

Sorry if some or all of this is obvious, but I knew none of this when I started out.

Tightness is everything. Well, that and rigidity. Both of the machine, cutters, collets and work piece, and I have to say, you are already onto a loser with the work piece being held vertically as you currently have it.

I would first suggest that the collet is not in the holder correctly. As others have said, the front face of the collet should be flush with the front of the collet nut. that could be why your cutter is slipping.

ER collets are designed to seat into an offset ring at the bottom of the nut. If you find your collet is left in the holder after releasing the nut, then the collet was not correctly inserted into the nut.

You should also ensure that both the tool holder taper (MT3) and the bore on the mill are free from grease, oil and dirt; as dirt and grease can, on occasion, prevent the taper from seating securely. Not to mention running an increased risk of scoring the internal taper.

It's also important that the drawbar is tightened sufficiently. Now, this, does NOT mean hauling as hard as you can on the top nut, the drawbar should be just about a quarter turn past finger tight, just enough to prevent the taper tooling from slipping. Do the drawbar up too tight and you end up having to wail on the top of it with a hammer to release the tooling from the taper and that can be bad for the bearings.

Also, the collet nut should be good and tight otherwise, again, you have the possibility of an end mill slipping.

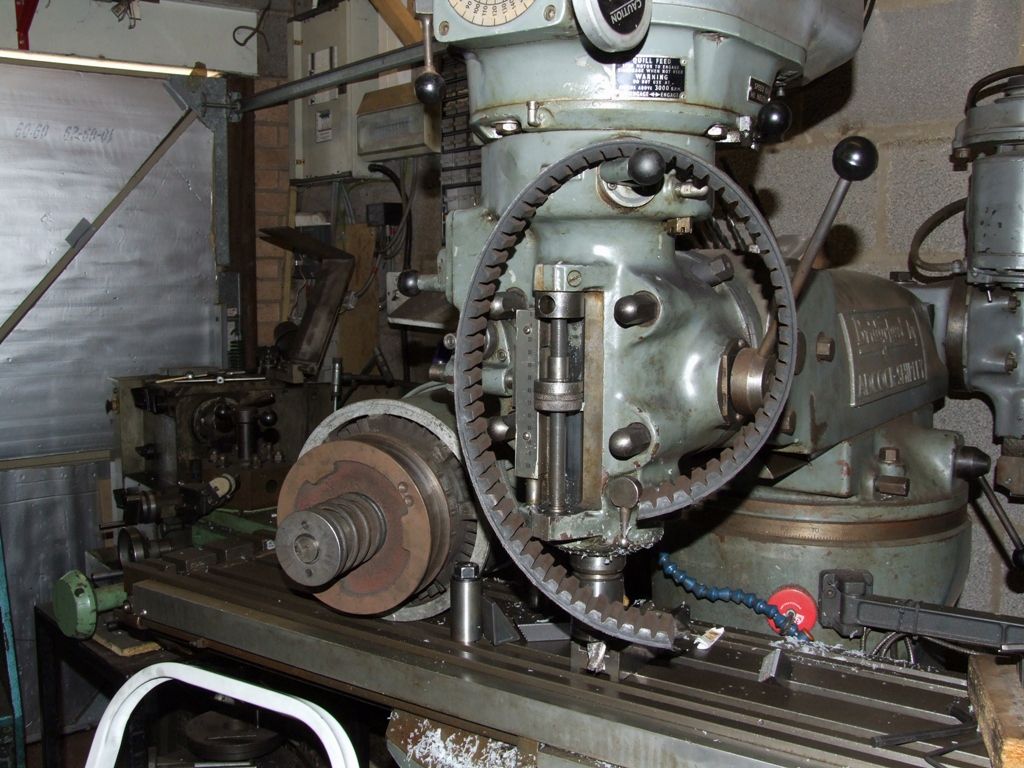

Most oriental milling machines benefit from the head of the machine being kept as low as possible, a setup I think you will agree, you do not have with your current setup.

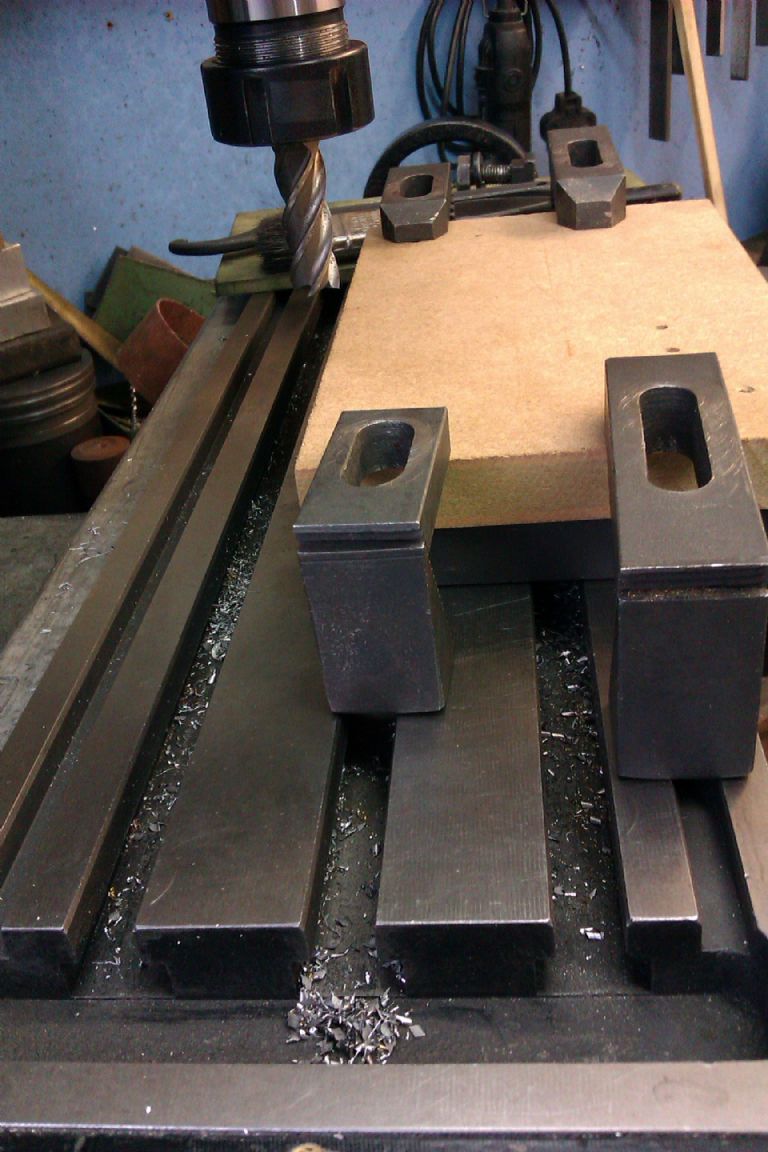

If at all possible, try to lay the plate flat on the table (With something sacrificial underneath it) and clamp it there, rather than have it as you have now, it's much more likely to result in a better finish.

Even though you have the vice clamped down there will still be movement.

Remember to lock off all unused axis on X,Y & Z. It may seem trivial but it makes a HUGE difference to how the machine reacts to a cut.

Know & respect the machines limitations.

These machines, although capable, are NOT industrial grade machines and should not be expected to perform as such. I would suggest that your cutter is too big for the machine. having looked at machines similar to yours, they quote a maximum cutter size of 12mm so as you can see 20mm is well above that suggested maximum.

I would also suggest that a 25mm cut is too big a cut to be taking all at once. Especially in steel. I have found that even with all the axis locked off chatter and excessive vibration will start.

Were I making the cut, I would have the plate clamped to the table and slowly lower the cutter down in increments until the cut is finished.

Do not try to climb mill, especially with such a large work piece, it will end in tears, ruined work and possibly a broken cutter. Again, these oriental machines are great at what they do but climb milling in thick steel isn't one of the things they do well. Ideally, especially when starting out, you should be using the conventional milling mode.

In conventional milling, the work piece is presented to the cutter AGAINST the rotation of the cutter, thus the cutter tries to push the work piece away from it.

In climb milling, the work piece is presented to the cutter WITH the rotation of the cutter, thus the cutter tries to pull the work into the cutter.

Climb milling is the setup you have pictured and as these machines are not as rigid as they could be (especially with the setup as pictured) you are asking for trouble. It's important to remember that the lead screws WILL have some play in them, even from new, and even with the unused axis locked off, the forces generated by the cutter can be enough to overcome the locks.

I suspect this, along with the less than ideal setup is your main issue.

Unrelated things to consider with ANY metalworking and especially powered metal working:

1. Did I tighten EVERYTHING down?

2. If it DOES all go wrong, what's the worst that can happen & how can I prevent it happening in the first place.

3. NEVER operate your machines while tired or feeling less than well.

4. There are days when everything seems to be going wrong. Don't fight it, shut down and walk away, it'll wait until tomorrow. Increased frustration leads to mistakes, leads to injury.

5. If it doesn't feel right, it almost certainly isn't. stop and check.

I apologise if my post seems to be all negative, I had no intention of it coming across like that.

For engineering videos, try You Tube, there are loads of videos on there that have helped me in the past but, do be aware that everyone has their own ideas of how things can and should be done.

Have fun and the very best of luck.

Bill.

Edited By Bill Robley on 26/05/2014 14:10:05

Edited By Bill Robley on 26/05/2014 14:11:37

Bob Brown 1.