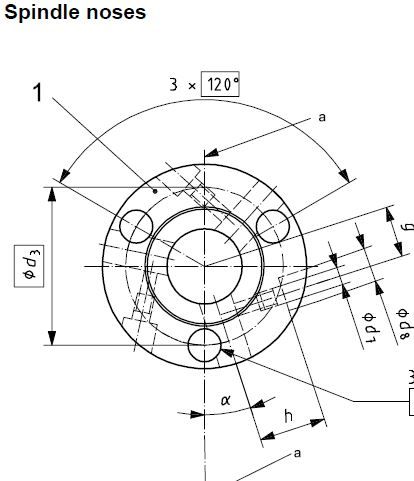

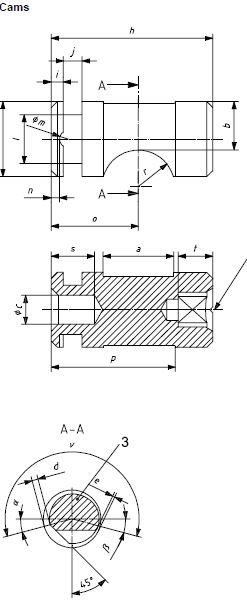

I created these parts in Alibre (now called Geomagic) using the 30 day trial. I also saved them as .PAR and .ASM files which work with Solidworks and Solid Edge – and 3D PDF files (for the models) and PDF (for the drawings). However, you lose the history (feature) tree when you export to another application like this, so if you wanted to edit them yourself it would be preferable to use Alibre. So if you have any of these CAD applications or just want the PDF and dimensioned drawings, that's no problem – let me know. Apart from the mounting bolt holes (to suit your setup), you could make most of it from the drawings.

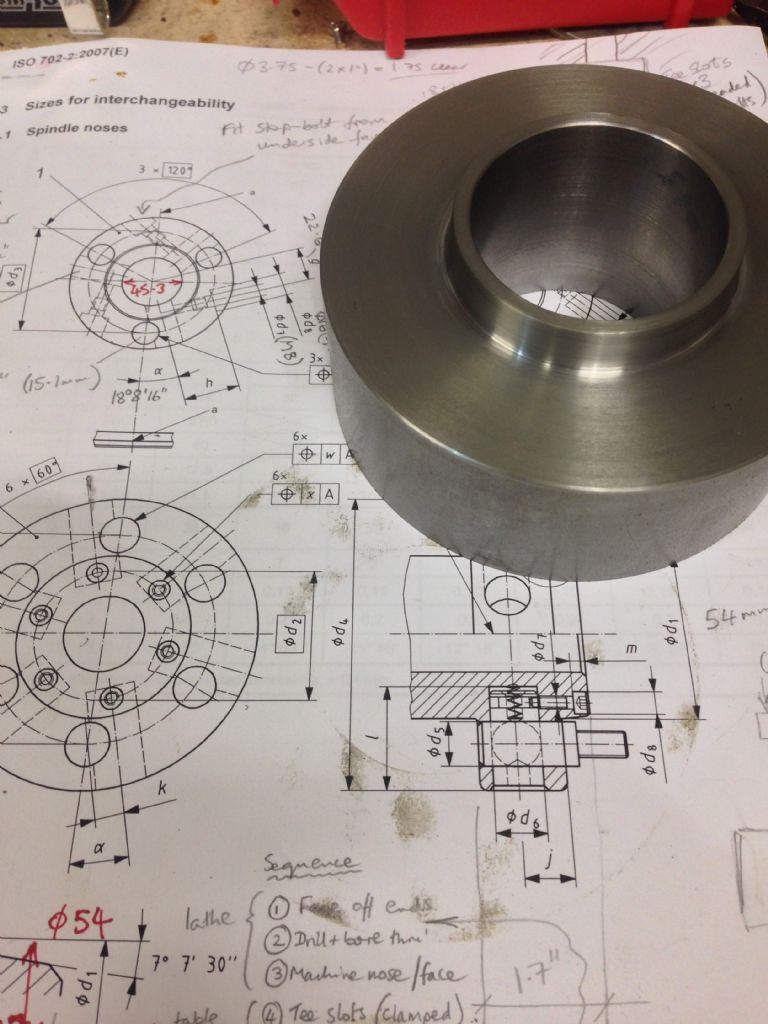

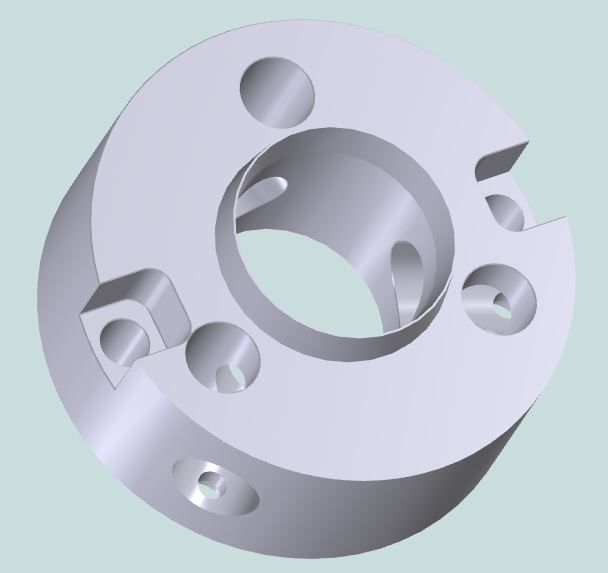

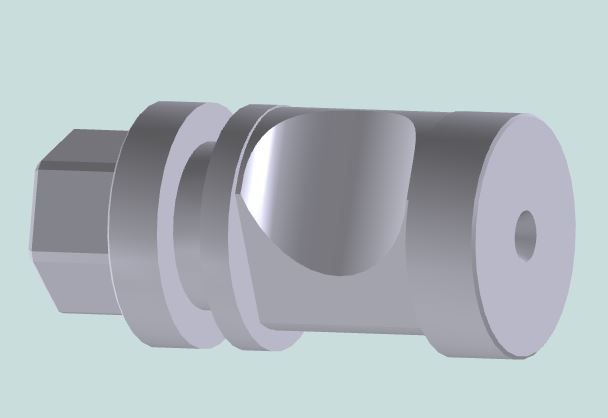

If you are planning on using one of these with a rotary table, it would be convenient if yours had 3 slots to start with. The D1-3 and D1-4 noses have 3 studs and my challenge was getting the 3 studs to co-exist with the 2 mounting slots within the adaptor. As I said, my task would have been easier if I'd started with a larger diameter lump of steel but I was brassic at the time, having just coughed up for a…..rotary table.

A lot of the work is done on the rotary table, so if you have one of these already, creating the fixing holes early on helps the workflow. I also found the DRO I fitted to my milling machine to be invaluable and I suspect I'd have made a pig's ear of it otherwise. I used a centre finder a lot on this job during setup with the DRO and I'm ashamed to admit I hadn't realised how they are supposed to be used until this point! The power of Youtube!

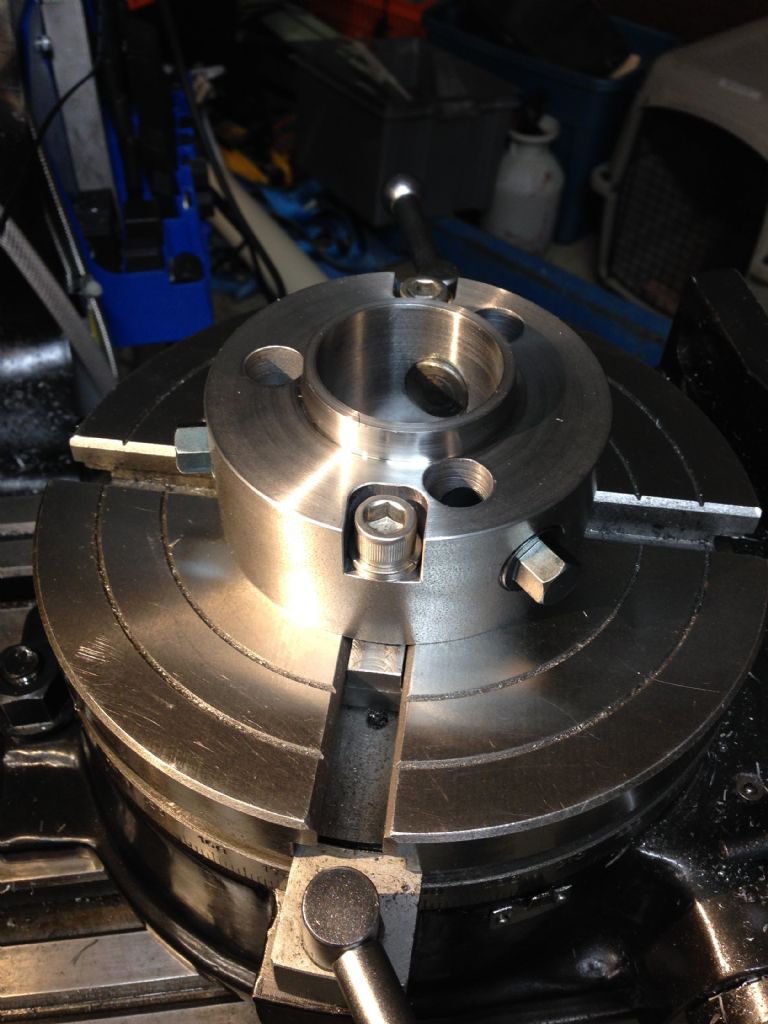

Apart from the various boring operations, careful setup of the 3 cams in the 4-jaw was the other critical activity but it all worked out nicely in the end. I've now used it a few times since I made it and it's been pretty useful.

I'm really not likely to write up anything for the magazine. I'm much more inclined to use my free time in the workshop but you'll notice I've created a couple of short photo journal type postings like this which I hope people find interesting in the same way I do when I browse other people's work looking for ideas and inspiration.

Muzzer

Nealeb.