Posted by Andrew Tinsley on 05/06/2022 10:09:16:

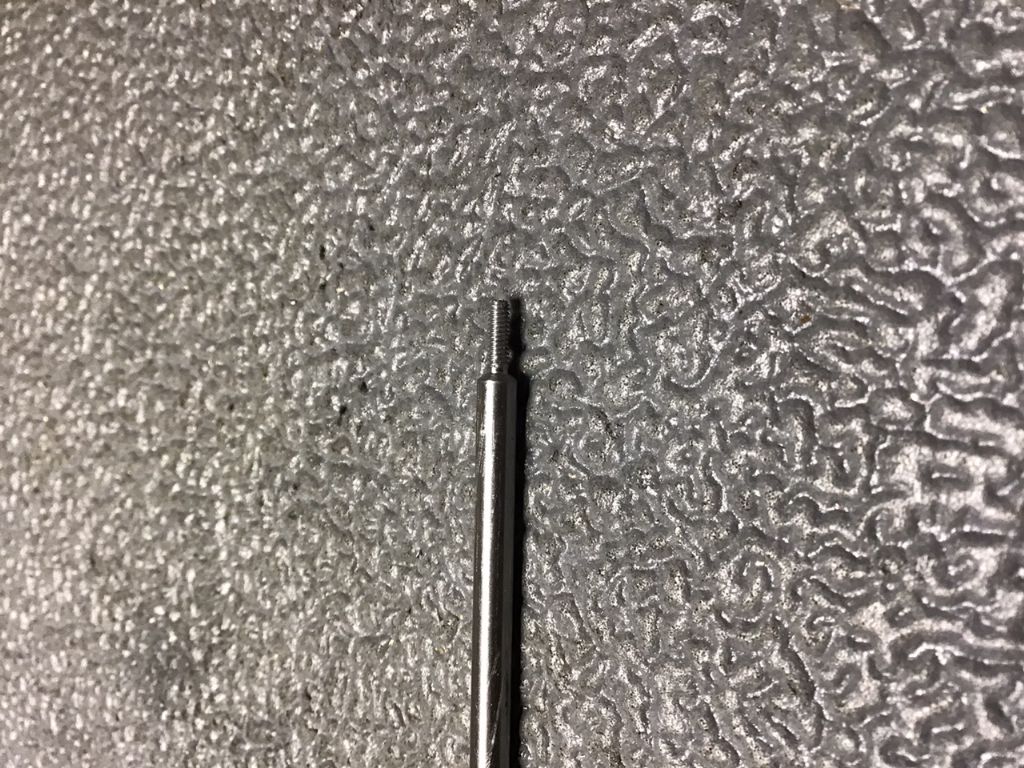

I have also had this problem recently. I needed to thread some silver steel 2BA. I used a die holder in the tailstock. First three were fine,then one like the OP's photo. The following four were just fine.

I can only think that the material was somehow faulty, accounting for the poor threading. A bit of a mystery!

Andrew.

Not impossible the material was faulty, but unlikely! I've noticed most of the 'poor materials' reported on the web are found in hobby workshops, not on production lines churning out thousands of identical items!

I suspect trapped swarf wedging into the die. As the die cuts down the rod, we hope the swarf escapes through the slots provided, but they aren't very big and there's always a risk swarf is going to get minced and pulled into the cutting edges. Enough of that will cause the die to blunt and jamb, and – because the screw thread provides a massive mechanical advantage – the turning force is enough to gouge the rod as it enters the die.

Not enough to be conclusive, but in my workshop:

- Brass never mangles.

- Soft Aluminium often strips,

- EN1A-Pb rarely strips

- Ordinary mild steel sometimes jambs and strips

- Some stainless steels are vile!

- Much more likely to happen cutting by hand when nothing apart from me is keeping the die straight. I put this down to the wobbly operator skewing the die into the rod.

- Power cutting with a die on the lathe rarely strips. I think this is all to do with steadiness; the die goes straight down the rod at a steady speed with no jerks or twists. I suspect the swarf comes off cleanly with enough energy to eject away from the cutting edges.

Assuming the rod is the correct diameter and the die in good condition, I think the answer is plenty of lube, periodically winding back the die to clear swarf, maintaining a steady cut-rate, and keeping the die absolutely straight.

Dave

Neil Lickfold.